AUT weld scanner

23/01/2025

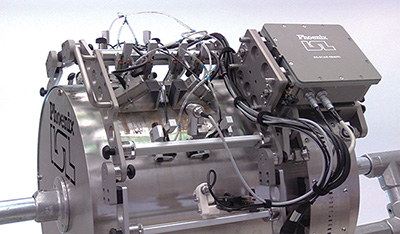

Phoenix Inspection Systems Limited has launched a new automated ultrasonic testing (AUT) weld scanner.

Orbital is a highly efficient solution that can inspect inside diameter (ID) and outside diameter (OD) pipe welds through to flat for tanks and vessels of any material, hold up to 12 ultrasonic testing (UT) probes and directly mount any compatible original equipment manufacturer (OEM) on-board acquisition unit, offering total versatility in one inspection solution.

The powerful scanner comprises an automated carriage with tracks that can adhere to any inspection surface via fully enveloping tension, magnets or vacuum in any orientation. The incorporated probe pan is configurable to inspection requirements and capable of holding a single UT probe up to a maximum of 12 probes simultaneously (diameter dependent).

Orbital can also transport a range of accessories to simplify site inspections, including a high-definition (HD) camera, global positioning system (GPS), thermal surface monitor and optional lighting. This combination of on-board solutions can provide a live visual assessment to support the most precise and efficient defect detection and data acquisition.

Ideal for pipeline girth weld inspection in the oil & gas industry as well as ID pipe weld inspection and welds in ferritic and non-ferritic tanks and vessels, Orbital is also suitable for use in the nuclear, power generation and aerospace

industries.

Orbital is a robust and dynamic scanner that is easy to set up with just one operator and provides an economical scanning solution for multiple applications.

|

Phoenix ISL