ETher NDE launches ET wheel inspection system

19/07/2011

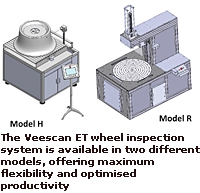

ETher NDE, a UK-based manufacturer of eddy current products, has introduced the Veescan ET wheel inspection system. The Veescan is ETher’s first wheel inspection system and is available in two different models: Veescan H for maximum flexibility and Veescan R for optimised productivity.

ETher NDE, a UK-based manufacturer of eddy current products, has introduced the Veescan ET wheel inspection system. The Veescan is ETher’s first wheel inspection system and is available in two different models: Veescan H for maximum flexibility and Veescan R for optimised productivity.The Veescan has a proven mechanical design and established record of breakdown-free operation for 365 days or more. Appealing to many companies in the aerospace industry and with the choice of two fully-featured options, the Veescan is ideal in all aircraft wheel-testing environments.

The Veescan can be configured with a wide choice of probes and allows any wheel testing facility the flexibility to select the system most compatible with their workload. Teamed with a full choice of operation modes, the Veescan maximises the probability of detection.

Available in two configurations, Veescan H is designed to lift the wheel and fix it with an automatic adaptor that uses the wheel inertia to centre it. Veescan H offers an integrated roller tray for easy manoeuvrability and integration into a conveyor system and can test wheels up to 900 mm in diameter. The Veescan H is designed with an adjustable-height control panel for operator comfort and can be positioned at a convenient distance from the main machine. Open on three sides, the Veescan H offers easy wheel loading as standard.

Alternatively, Veescan R clamps the wheel to a turntable with a pneumatic cylinder. With pneumatic control and electronics fitted into the frame, it allows access to the rotating table from both sides. On the rotating table, three rollers assist the wheel movement from three open sides. Able to test wheels of two size ranges, under 600 mm and 900 mm, simultaneously, the model R is as flexible as it is robust and reliable.

The Veescan is offered with the ETher NDE guarantee of complete client satisfaction and excellent technical support, inclusive of a two-year warranty.

John Hansen, Managing Director, said: “The Veescan product range offers our clients the ability to improve both inspection productivity and the quality of inspection, with low cost of ownership.”

www.ethernde.com