Product Technology Online Training

Introduction

In response to a demand from industry, ISO 9712:2022, the standard to which the PCN Scheme operates with respect to NDT certification, now requires that all candidates demonstrate a prior understanding of materials and processes, also known as 'product technology', before undertaking training in any method in order to supplement their knowledge of the specific methods and techniques to which they are seeking certification.

To meet this requirement, BINDT has developed a new interactive online Product Technology training course to help PCN candidates achieve the required knowledge in a convenient way and at a time and pace that suits them.

The course is now available worldwide.

Click here to enrol and take the course.

This link will take you to an external website.

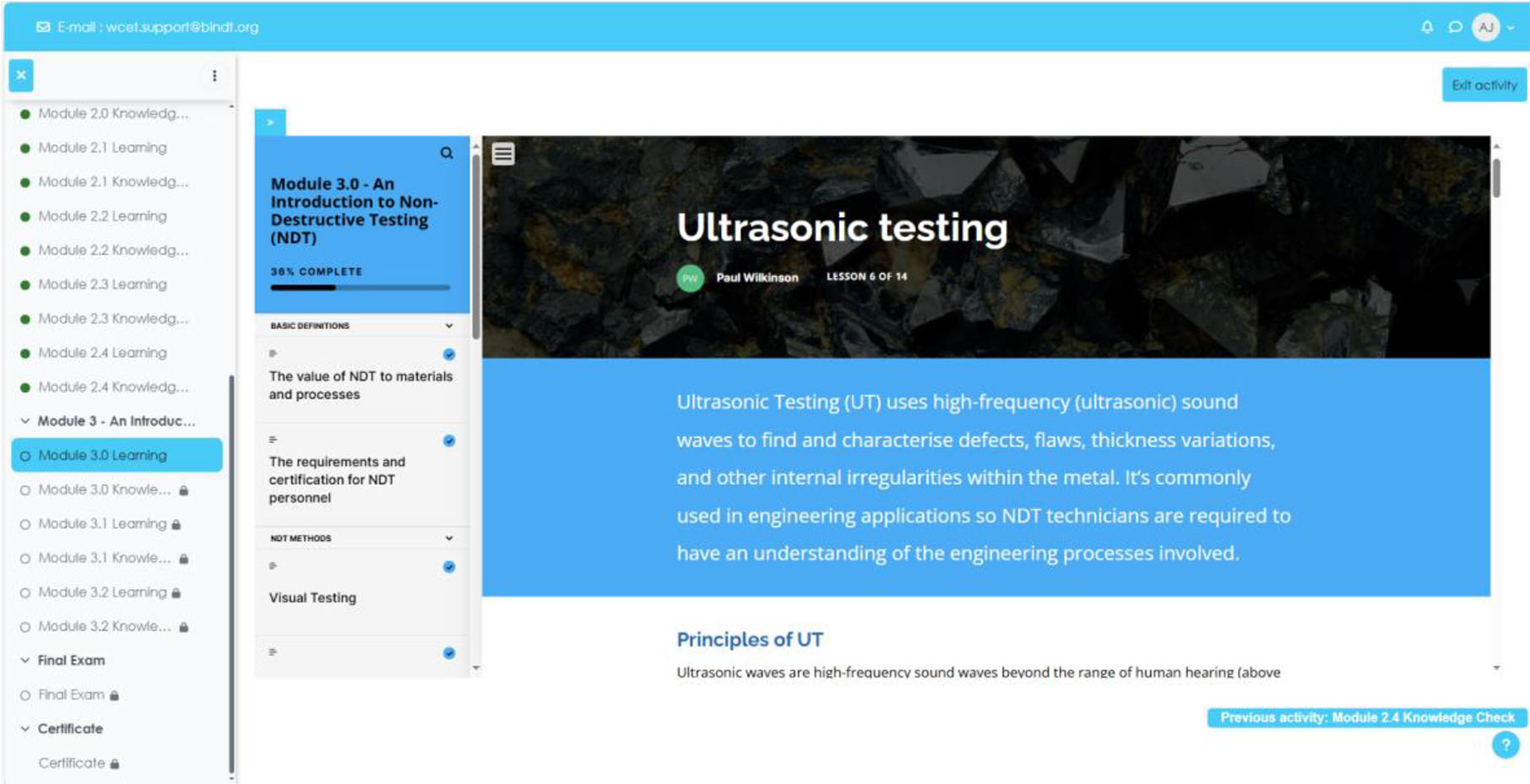

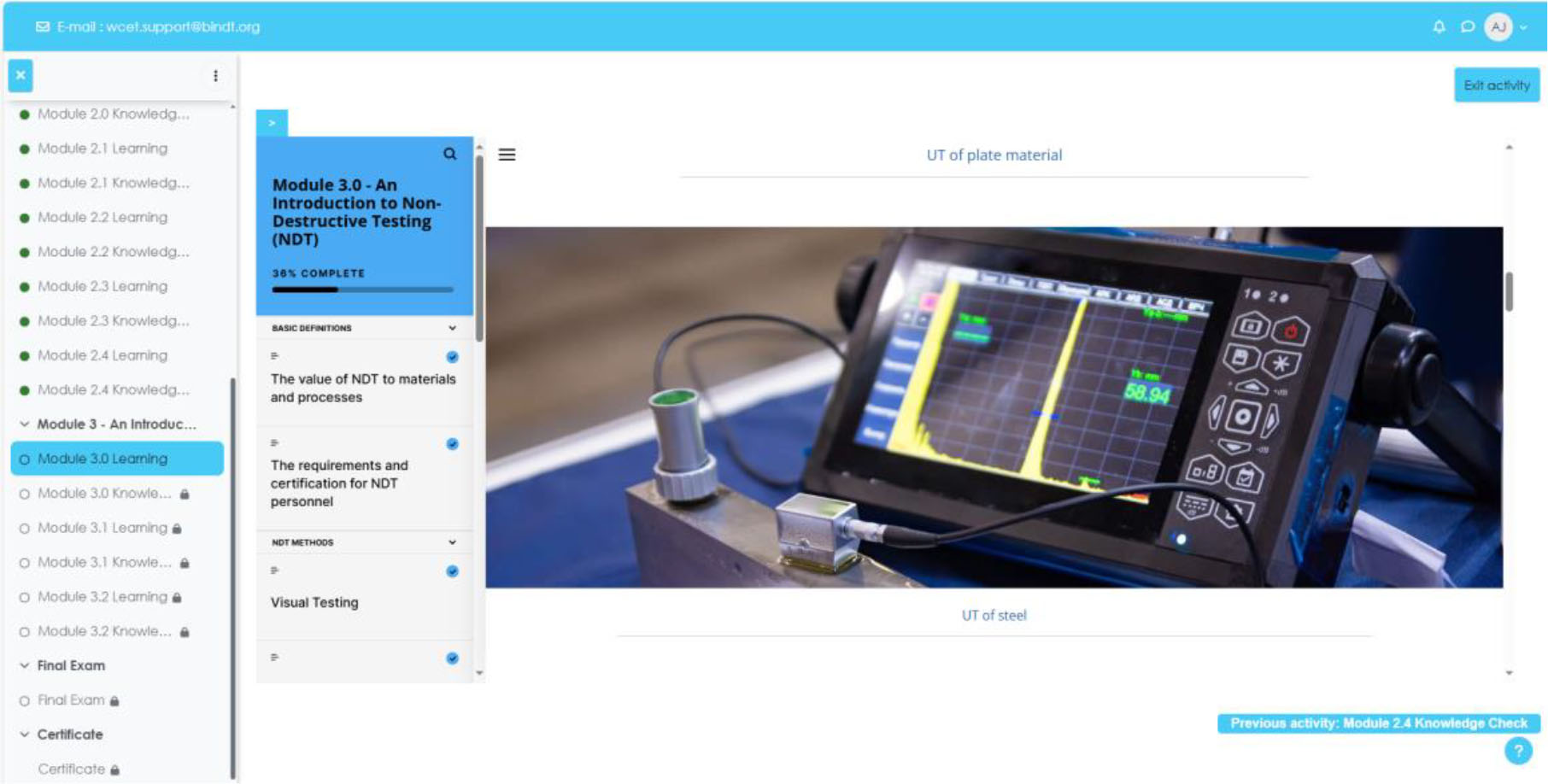

The online training course includes learning modules covering industrial materials, manufacturing processes and an introduction to non-destructive testing (NDT), with material presented in a clear and concise format through a range of videos, high-resolution images and graphs. Course content is organised in a logical manner, starting with how metals are created, through the processing of the raw materials to form components and the NDT methods and applications used to inspect them.

Interactive reading material requires candidate interaction both during the online training element and throughout the course assessments, featuring the use of traditional multiple choice-type questions and other questions that require candidates to select the most appropriate images and place them alongside the relevant text. Progress is automatically saved as candidates progress through the modules, meaning the course can be taken at the user’s pace.

The interactive element within each individual learning module has been carefully designed to make learning stimulating and enjoyable and to ensure that the candidate retains the required information through assessment at the end of each section.

The training module requires aspirant PCN candidates to successfully complete each individual section before demonstrating their knowledge in an end-of-course assessment, confirming their understanding of materials science and processes and the associated discontinuities that an NDT operative might encounter when deploying NDT within an industry and/or product sector(s).

A digital ‘Product Technology’ certificate will be issued following successful completion of the online training and achieving a pass in the end-of-course assessment.

There is a nominal charge of £60.00 + VAT to cover the cost of online hosting of the course, payable when signing up to start the course.

Access to the course will be available for 365 days from the date of purchase. (Please note that address details for the candidate will need to be provided for invoicing purposes.)

Where the facility is available, PCN entrants will have the option to carry out the Product Technology training at a BINDT ATO (at an additional cost determined by the ATO).

The course is mandatory for all new PCN entrants and is also recommended as an efficient and enjoyable way for anyone simply wishing to refresh their knowledge of materials and processes.

Course Content

Module 1.0 – Industrial Materials

Introduction • Objectives • Industrial materials • Engineering materials • History of manufacturing • Importance of manufacturing • Industrial relationships • Types of energy • Industrial materials • Processing steps • Metal process flow • Material consideration – process selection • Effects on properties due to manufacturing • States of matter • Shape-changing processes

Module 1.1 – Material Imperfections

Classification of materials • General properties of engineering materials • Composition of materials • Solidification, phases and microstructure • Heat treatment of metals • Influence of environment on properties • Material imperfections

Module 1.2 – Introduction to Material Properties

Introduction to material properties • Chemical properties • Acoustic properties

Module 1.3 – Industrial Materials

The production and properties of common metals used within industrial sectors • Polymers, ceramics and composite materials

Module 2.0 – Manufacturing Processes and Castings

Introduction to castings • Casting practices • Casting quality and defects

Module 2.1 – Manufacturing Processes and Forging

Introduction to metal forming • Forging • Sheet metal working • Powder technology

Module 2.2 – Joining Processes

Joining processes • Principles of arc welding • Weld discontinuities and defects

Module 2.3 – Material Removal Processes

Machine processes • Grinding

Module 2.4 – Surface Treatments and Coatings

Surface treatments and coatings

Module 3.0 – An Introduction to Non-Destructive Testing (NDT)

Basic definitions (the value of NDT to materials and processes, the requirements and certification for NDT personnel) • NDT methods (visual testing, penetrant testing, magnetic testing, ultrasonic testing, guided wave testing, radiographic testing, electromagnetic testing, acoustic emission testing, leak testing, laser testing, vibration analysis, spectroscopy)

3.1 – NDT Applications

NDT and manufacturing relationship • Materials characterisation • NDT of products • Failure of materials

3.2 NDT and Engineering

Role of NDT engineers • NDT procedures and acceptance criteria • Design for inspectability • NDT/inspection plans • NDT probability of detection (POD) • Fitness-for-service assessment (FFSA)

The BINDT Early Careers Branch hosted a Product Technology for beginners meeting presented by Patrick Boulton, Technical & Certification Engineer, BINDT. During the presentation, Patrick discussed the launch of the new interactive online Product Technology training course. Watch the full video to learn more at: https://www.youtube.com/watch?v=TR1k4iXqluQ

For further information contact: Certification Services Department, The British Institute of Non-Destructive Testing,

Midsummer House, Riverside Way, Bedford Road, Northampton NN1 5NX, UK. Tel: +44 (0)1604 438300; Email: pcn@bindt.org