Patent granted for STARS mapping capability to Eddyfi Technologies for through-coating imaging

02/01/2019

Equipment manufacturer Eddyfi Technologies has recently been granted a patent (number EP2506003A1) for its proprietary technology to map near-surface discontinuities on ferrous materials through thick coatings in excess of 10 mm. As magnetic flux leakage (MFL) signals alone are unable to reliably discriminate between near-side and far-side material loss, the complementary surface topology air-gap reluctance sensor (STARS) approach was designed to perform discrimination automatically.STARS technology is included in the company’s flagship MFL tank floor scanner, the Floormap3Di-R, which uses an array of sensors to give a clear presentation of product side features with an image of the plate surface that is nearly photographic in quality. With STARS, the Floormap3Di-R can automatically make product-side or soil-side calls on MFL data and display these calls as near-side and far-side maps.

STARS works on the principle of air-gap reluctance located under the magnetic poles of the tank floor scanner. Any deviation in the air gap, by a near-side defect for example, causes a change in the reluctance of the magnetic path and thus a change in flux density amplitude. The shape of the defect can also influence the direction of the magnetic field to provide phase information. In the region of a defect, the magnetic field will take the path of least reluctance. Then, during a scan, as a defect passes under the pole, the field lines will direct towards the sides of the defect profile. So the flux density not only changes in strength, but also in direction. The field direction is a key component to the high-resolution images that can be created with the STARS approach because it creates a bipolar signal, which identifies the rising or falling edge of a defect’s profile. As shown in the first image, a near-surface map of the plate is obtained with a detailed representation of corrosion features that can help inspectors identify the shape of corrosion and its distribution across large areas.

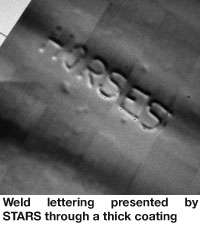

STARS not only responds to a loss of ferrous material but also to additional ferrous material, such as remnant welds. The ‘HORSES’ image is an interesting example to help illustrate all of the above. Most tank bottoms do not have lettering welded onto them. However, this is a real-world example of welding being practised on a tank floor, which was then detected by STARS underneath a non-ferrous thick film coating.

STARS not only responds to a loss of ferrous material but also to additional ferrous material, such as remnant welds. The ‘HORSES’ image is an interesting example to help illustrate all of the above. Most tank bottoms do not have lettering welded onto them. However, this is a real-world example of welding being practised on a tank floor, which was then detected by STARS underneath a non-ferrous thick film coating.The phase change from additional material applied to the floor of this storage tank is identified as the colour transitions from white to black, whereas the signal phase of material loss tends to be from black to white. Some minor product side pitting can also be seen surrounding the weld, demonstrating this discriminatory phase change. This is an excellent classification tool, when reviewing MFL data, for recognising MFL ‘false calls’ due to passing the scanner over remnant welds.

Stuart Kenny, General Manager of Eddyfi Technologies, based in Swansea, said: “STARS technology is another great example of how Eddyfi Technologies, through the Silverwing brand, is pushing the boundaries with sensor development and analysis software. Although specifically designed to help MFL operators differentiate between near-side and under-side corrosion, we believe there are vast applications that would benefit from high-resolution imaging through standard coatings and other protective layering.”

Stuart Kenny, General Manager of Eddyfi Technologies, based in Swansea, said: “STARS technology is another great example of how Eddyfi Technologies, through the Silverwing brand, is pushing the boundaries with sensor development and analysis software. Although specifically designed to help MFL operators differentiate between near-side and under-side corrosion, we believe there are vast applications that would benefit from high-resolution imaging through standard coatings and other protective layering.”www.eddyfi.com