‘Vivid’ images for improved quality assurance of steel components

06/07/2020

Parents-to-be are familiar with them – ultrasound images of their unborn child: pin sharp and brilliant, they convey an almost photorealistic level of detail and a deep impression of the child in the womb. The Fraunhofer Institute for Nondestructive Testing IZFP is researching and developing a technology to bring this type of vivid image to industrial applications. As part of a project funded by the German Federal Ministry of Education and Research (BMBF), scientists at the research institute in Saarbrücken have started to develop a novel imaging method that will generate vivid images of microstructural changes and stress distributions in real time. This technology will provide significant information on the load capacity and lifetime of steel components in a completely new way.Material properties affect the load capacity and service life of steel components. Particularly in the case of safety-relevant components, their reliable and fast quality assurance with optimised real-time capacity is indispensable for the prevention of unwanted changes in the microstructure and unwanted residual stresses in the material. Such alterations can already arise during production, but also after completion and commissioning. Due to their negative influence on product quality and suitability for use, they are highly relevant for both operational safety and added value.

Until now, there has been no technology for the fast and non-destructive determination of microstructure and residual stress distributions for industrial quality assurance in the case of lateral resolution or where high depth resolution is required. For safety-relevant components of different size scales, for example in the automotive and railway industries or for power plant components, there is a considerable need in this respect.

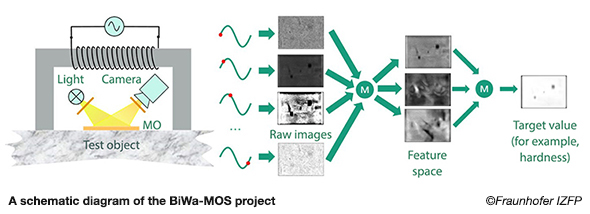

“The direct objective of this research project comprises the development, testing and validation under laboratory conditions of a novel imaging method for non-destructive material analysis by means of magneto-optical sensor technology. The innovative aspect of the project relates to the combination of the current state of magneto-optics with that of micromagnetics and thus to the application of optical technologies in the field of quality assurance,” explained Dr Madalina Rabung, responsible project leader and scientist at Fraunhofer IZFP. With the help of this method, a non-destructive magneto-optical system will be developed and tested that will be able to visualise the distribution of microstructure and stresses over large component surfaces down to a depth of approximately 1 mm below the surface. The near-surface spatial resolution is better than 50 μm and the method will generate and record the images within a few seconds.

The ‘BiWa-MOS’ project – imaging material analysis using magneto-optical sensor technology for rapid quality assurance of steel components – deals with the development of non-destructive methods for quality assurance and condition assessment of steel and cast iron components. Through the approach of an imaging method for material analysis based on magneto-optical procedures, the brilliance of vivid images showing unborn babies in the womb will be realised by other means for use in industrial settings.

The ability to extract and process parameters from magneto-optical images for immediate visualisation of the surface distribution of material properties represents a milestone for the transition of classical non-destructive testing (NDT) to intelligent cognitive sensor systems. In this context, the development of material innovations within the framework of the Industry 4.0 concept plays a decisive role.

“As a completely new method for spatially resolved material analysis, our process approach utilises optical technologies for quality assurance in product development and component monitoring,” continued Dr Rabung. This new method, capable of real-time application, for the visualisation of microstructural changes and stress distributions to the highest quality is the basis for non-destructive real-time imaging material analysis, for which an enormous scientific and, prospectively, also economic potential exists.

The field of non-destructive magnetic materials characterisation has been, and continues to be, significantly improved by Fraunhofer IZFP. For more than 30 years, the institute has been engaged in the indirect determination of mechanical properties (hardness, strength, etc) using magnetic effects (for example magnetic hysteresis, Barkhausen noise and eddy currents).

The Fraunhofer-Gesellschaft (the Fraunhofer Society), headquartered in Germany, is a world-leading applied research organisation. With its focus on developing key technologies that are vital for the future and enabling the commercial exploitation of this work by business and industry, Fraunhofer plays a central role in the innovation process. As a pioneer and catalyst for groundbreaking developments and scientific excellence, Fraunhofer helps shape society now and in the future.

Founded in 1949, the Fraunhofer-Gesellschaft currently operates 74 institutes and research institutions throughout Germany. The majority of the organisation’s 28,000 employees are qualified scientists and engineers, who work with an annual research budget of €2.8 billion (approximately £2.5 billion).

Of this sum, €2.3 billion (approximately £2 billion) is generated through contract research.

www.izfp.fraunhofer.de