Advanced Nuclear Research Centre’s manufacturing project AWESIM gets go-ahead from UK government

04/11/2020

A pioneering project that aims to embed inspection, closed-loop control and automation directly at the point of welding to deliver high-quality welds more accurately first time has won government backing.

A pioneering project that aims to embed inspection, closed-loop control and automation directly at the point of welding to deliver high-quality welds more accurately first time has won government backing.The Automated Welding Equipment System Inspection and Monitoring (AWESIM) project introduces groundbreaking technology that brings together machine learning, sensor development and advanced remote manufacturing processes to deliver welding, weld inspection and potentially weld certification all in near real time, thus providing the opportunity to create significant savings in terms of time, rework and cost. This will be achieved via the early detection of flaws as and when they arise; hence the ability to make significant savings in the manufacturing of nuclear components.

The work is being driven by urgent UK industry targets to achieve a 30% cost reduction in nuclear new build along with savings of 20% in nuclear decommissioning projects by the year 2030.

The Department for Business, Energy and Industrial Strategy (BEIS)’s Energy Innovation Programme (EIP) will allocate £1.3 million for phase 1 of the project, which will focus on technology development and last until the end of March 2021. The remainder of the funding will come from the industrial partners. Once developed, the technology will enable the detection of flaws as they occur, leading to significant reductions in cost and time in manufacturing processes.

The University of Strathclyde’s Advanced Nuclear Research Centre (ANRC) will develop a non-destructive examination system with Derbyshire engineering company Peak NDT as part of the project.

Cavendish Nuclear, working in collaboration with Doosan Babcock, will provide engineering expertise to ensure the technology is industry-ready.

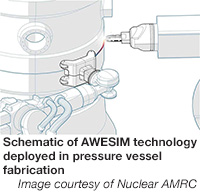

A large factory-scale demonstrator to showcase the integrated technologies will be built at the University of Sheffield’s Nuclear Advanced Manufacturing Research Centre (Nuclear AMRC) later this year.

Dr Charles MacLeod from the Centre for Ultrasonic Engineering at the University of Strathclyde, who is delivering the pioneering research in manufacture and sensor technologies, stated: “This funding, secured through the BEIS Energy Innovation Programme, enables the University of Strathclyde and ANRC to further translate this novel automated in-process inspection research through the Technology Readiness Levels.

Dr Charles MacLeod from the Centre for Ultrasonic Engineering at the University of Strathclyde, who is delivering the pioneering research in manufacture and sensor technologies, stated: “This funding, secured through the BEIS Energy Innovation Programme, enables the University of Strathclyde and ANRC to further translate this novel automated in-process inspection research through the Technology Readiness Levels.This research, previously developed under the £2.6 million Engineering and Physical Sciences Research Council (EPSRC) Prosperity Partnership, will deliver impact and benefit directly to the nuclear industry at pace and at scale, ensuring that this critical UK engineering sector continues to advance with cutting-edge and high-value manufacturing and asset repair activities.”

Professor Campbell Booth, Head of the Department of Electronic and Electrical Engineering at the University of Strathclyde, commented: “How great it is to have ANRC hosted in one of the largest and foremost EEE departments, and it is fantastic to witness ANRC’s success, with the work bringing together multiple disciplines and, importantly, assisting the department and the university in translating our research into industrial and commercial impact.”

Mark Gayfer, Professor of Practice and CEO of the Advanced Nuclear Research Centre, said: “I am proud and delighted that the University of Strathclyde’s ANRC is able to play a key role in developing this game-changing technology. As a leading international technological university, this ambitious and innovative project plays to our strengths and those of our team of cutting-edge researchers in this field and I look forward to seeing the impact of this research across the nuclear sector and beyond in the years ahead.”

www.strath.ac.uk/research/advancednuclearresearchcentre