Bloodhound SSC revealed in London’s Canary Wharf

22/10/2015

The Bloodhound SuperSonic Car (SSC) is on course to become the world's fastest and most advanced land vehicle and is the product of eight years of research, design and manufacturing, involving over 350 companies and universities. On Friday 25 September 2015, the Bloodhound SSC made its world debut in London's Canary Wharf, with 8000 visitors attending what turned out to be one of the STEM events of the year.

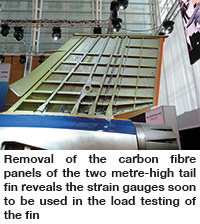

The Bloodhound was on display in the East Wintergarden Conference Centre, Canary Wharf, with one side of the car removed to show its inner workings and components. This included one side of the two metre-high tail fin, on display for the first time. The fin is required to keep the car stable while it travels at supersonic speeds of up to 1000 mph. With the skin panels removed, the numerous wires and strain gauges were revealed. The gauges used to monitor the loads on the fin are soon to be calibrated, a process that involves the fin being horizontally clamped to a wall and loaded with a known weight to see how much it deflects.

Safety is critical on the car and therefore this is not the only type of testing the car has undergone during its construction. The Bloodhound SSC has a carbon composite forward structure and a bonded and riveted rear structure with the fuselage skin made from titanium sheets with aluminium frames. The lower chassis is constructed using aluminium ribs and steel sheets that are also bonded and riveted. This process can leave the substrate and the adhesive open to separation or delamination, weakening the structure. Therefore, the team needed to determine the extent of any separation since the initial build and NDT was an essential requirement. Resonance-based equipment was used on the structure to detect any gaps in the layers and bond separation. A few tweaks were made to the chassis as a result of the testing, as there were one or two areas requiring attention.

One of the main concerns of running the Bloodhound SSC in the desert at supersonic speeds is the risk of debris causing damage to the body and ultimately endangering its driver, Andy Green. To minimise this risk, an area of two miles wide and 12 miles long has been cleared by hand on the Hakskeen Pan in the Mier area of the Northern Cape of Africa, where the Bloodhound SSC will attempt its world record. The underside of the car is steel and, for added safety, the sides of the cockpit are protected with ballistic armour to shield the driver against the debris.

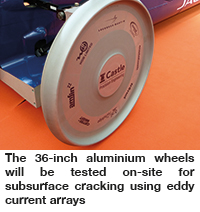

The 36-inch aluminium wheels need to be carefully monitored; this is another job for NDT. The wheels will be tested on-site for subsurface cracking using eddy current arrays between each run to see if they have been damaged. This is a relatively quick process that involves running a probe around the rim of each wheel to obtain a detailed picture; this same equipment may be used to inspect other parts of the car for damage such as potential impacts to the exposed suspension components or fatigue cracks in the aluminium alloy chassis frames. Testing at these stages will assist the team in acting fast where a possible safety issue is present and, as with all NDT methods, the idea is to carry out the tests without causing any damage to the car.

Other areas of the car due to be tested include the airbrake doors. The Bloodhound SSC currently has replica airbrake doors made from plywood in place to ensure that the hinges are aligned correctly and to enable the team to start constructing the mechanism while the actual doors, which will be carbon fibre composites, are in the manufacturing stage. The doors will open out whilst the vehicle is travelling at supersonic speed and therefore need to withstand the severe vibrations produced in order to slow the car sufficiently before the wheel brakes may be activated. Again, the same equipment as used in the testing of the chassis, wheels and frame will be used to ensure the bond will stay together, without having any deleterious effect on the car. Roland Dennison, Engineer Lead – Stress Analysis, said: “Olympus is one of a number of organisations providing tremendous support to Bloodhound by supplying not only various test equipment but also the expertise necessary to ensure accurate interpretation of the test results. A great help indeed.”

With the car almost 95% complete, the team has announced that it is now preparing for its first challenge of reaching 800 mph on 15 October 2016. If achieved, this speed alone will break the current land-speed record of 763.035 mph, set by Andy Green in 1997 with the British jet-propelled car Thrust SSC. However, the goal is to eventually push the record above 1000 mph.

See NDT News for news and updates on the progress of the Bloodhound SSC Project and the role of NDT and CM in it.