Metrology service provider expands with second LK coordinate measuring machine

19/09/2019

Contract inspection and reverse engineering capacity has doubled in terms of throughput, while the size of components that can be measured has increased more than five-fold at Laser Scanning Ltd, based in Chapeltown, near Sheffield. This follows the installation of a second, larger coordinate measuring machine (CMM), built by LK Metrology at its Castle Donington factory.The latest LK 20.12.10 ceramic bridge CMM with 2000 x 1200 x 1000 mm working volume has joined a smaller 8.7.6 model. When Johnathan Rigby, Laser Scanning’s Managing Director, started the company in September 2016, he brought the original machine with him from his previous employer, PMS Diecasting, Rotherham. This firm now subcontracts much of its metrology requirement to Laser Scanning, with both firms being members of the Glide Group, along with plastic injection moulding specialist Loadhog, toolmaker GoTools and wire joining and tensioning product manufacturer Gripple.

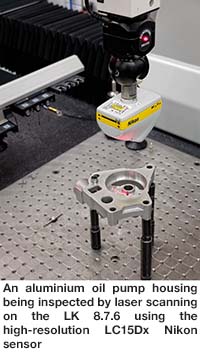

As the inspection provider’s name implies, most data acquisition is carried out by laser scanning on both of the LK CMMs, as well as on two articulated arms supplied by Nikon Metrology. All of the equipment is housed in a temperature-controlled room, held at 20 ±1°C, at the Chapeltown facility. Parts delivered for inspection are acclimatised in the same room for 24 hours to reduce measurement uncertainty.

Three types of non-contact sensor from Nikon Metrology are in use on the CMMs: an XC65D cross scanner and line scanner models L100 and LC15Dx, which provide a measuring accuracy of 13 µm, 6.5 µm and 1.8 µm, respectively. The latter provides performance equivalent to tactile probing, which is also utilised by Mr Rigby and his team for capturing physical dimensions, such as hole diameters, using a TP20 touch probe and an SP20 scanning probe, both from Renishaw. A changing rack mounted on the CMM table allows automatic sensor exchange to be performed within an inspection cycle.

The purchase of the larger CMM was prompted by Mr Rigby’s receipt from JCB Power Systems, Derby, of a contract to assist with the quality control (QC) of cylinder blocks and heads for the engines that power the original equipment manufacturers (OEMs) off-road vehicles. JCB has its own LK machine equipped with a touch probe that serves the production line in Derby. Laser Scanning assists by providing measurement and inspection of goods that are received, where it has a QC engineer permanently stationed.

Additionally, the Chapeltown centre helps out with preparation of CMM programs and proving them out, as well as inspecting prototypes to support JCB’s research and development department. Especially for this purpose, the service provider is able to furnish much more comprehensive and accurate information about a new component than is possible using touch probing techniques at JCB Power Systems.

Although the engine plant does have laser scanning capability on an articulated arm, the level of detail that can be acquired is less, as its scanning resolution is 23 µm, much lower than the best CMM-mounted scanner in use at Laser Scanning’s offices in Chapeltown. In any case, inspection using an arm would be a manual process and almost impossible to replicate on subsequent occasions, whereas running a program on a CMM is automated and provides a high level of repeatability.

Mr Rigby explained: “By working with JCB’s inspection department and research and development (R&D) team, we have been able to free up our customer’s machine to concentrate on production QC. They also appreciate the greater detail we are able to provide about new prototypes, as laser scanning allows us to show them the form of a component as well as supply measurement data.

“For example, they recently asked us to help them with a new rocker cover housing that had been plastic injection moulded, to determine whether the gasket area was within tolerance after shrinkage in the manufacturing process.

“For example, they recently asked us to help them with a new rocker cover housing that had been plastic injection moulded, to determine whether the gasket area was within tolerance after shrinkage in the manufacturing process.“Inspecting a planar surface such as the gasket area by touch probing at multiple points would not give an overall idea of its flatness and, in all probability, if the exercise were repeated the results would be different.

“In contrast, scanning generates millions of points to provide a detailed 3D picture of the entire surface to a very high level of precision and the deviations can be quantified. It enables JCB to show its mould tool supplier exactly where any inaccuracies are.”

The Chapeltown metrology company is ideally placed to help any manufacturer that uses LK measuring machines and software, as work and programs can be transferred seamlessly to run on either CMM. Projects have involved a Midlands-based tier-2 supplier to the global aerospace industry, which used Laser Scanning’s subcontract services for inspecting components while its own machine was out of action, and a medical equipment manufacturer that wanted to verify its in-house QC capability. Operator holiday cover is another regular source of business.

About half of Laser Scanning’s turnover is derived from reverse-engineering legacy components for which models and drawings do not exist. Machine shops and toolmakers are frequent customers and the company also provides a service to designers. A recent job entailed taking sketches for the frame of a new downhill mountain bike developed by Stewart Palmer, Director of F1 subcontractor North Bucks Machining, and creating a 3D computer-aided design (CAD) model so that the frame elements could be produced on one of its machining centres. The contract machinist is also an LK CMM user.

The latest version of LK CAMIO software, version 8.5, is in use at the Chapeltown facility. Featuring interoperability across CMM platforms and sensor technologies, it is designed to create efficient inspection programs for measuring geometrical features and evaluating surfaces using advanced point cloud analysis, with part-to-CAD comparison and full reporting capability.

The latest version of LK CAMIO software, version 8.5, is in use at the Chapeltown facility. Featuring interoperability across CMM platforms and sensor technologies, it is designed to create efficient inspection programs for measuring geometrical features and evaluating surfaces using advanced point cloud analysis, with part-to-CAD comparison and full reporting capability.Mr Rigby concluded: “CAMIO software has a Microsoft Office feel to it, with a similar, customisable icon ribbon at the top of the screen. It is very user friendly, as programming functions are easily accessible and not buried within drop-down menus.

“The new version interfaces with our Geomagic software from 3D Systems, allowing us to create accurate models from 3D scan data as well as use it for QC and measurement.

“We regard our association with LK and also Nikon as two-way partnerships, whereby they provide us with all the support we need and we feed back information to the OEMs to assist in their development of the next generations of products.”

Laser Scanning is accredited to ISO 9001 for quality management, ISO 14001 for environmental management, OHSAS 18001 for occupational safety and health and ISO 27001 for data security. It is a member of the Gauge and ToolMakers Association (GTMA), the Federation of Small Businesses (FSB) and the Employee Ownership Association (EOA).

www.laser-scanning.co.uk

www.lkmetrology.com