High-precision 3D measurement sensor

14/09/2021

Precision sensor manufacturer Micro-Epsilon has introduced a new range of high-precision 3D snapshot measurement sensors that are suitable for automated in-line measurement of the geometry, shape and surface quality of objects. The sensors stand out due to their extremely high resolution and repeatability, as well as their large measuring area.The new surfaceCONTROL 3D 3500 is a 3D snapshot sensor with a compact design and extremely high resolution in the Z-axis (from 1.0 µm). With repeatability of up to 0.4 µm, the sensor is said to set a new benchmark in high-precision 3D measurement technology. Due to its high performance, the sensor is able to reliably detect even the slightest of deviations in planarity, for example, or height differences of very small components (for example IC pins) on printed circuit boards (PCBs). A high data processing speed of up to 2.2 million 3D points per second enables the sensor to increase productivity in the respective application.

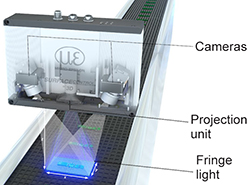

The surfaceCONTROL 3D 3500 sensor operates on the principle of optical triangulation based on fringe projection, which allows direct 3D measurement of components to be performed. Using a matrix projector, a sequence of patterns is projected onto the surface of the target object. The light from the patterns is viewed and recorded by two cameras either side of the projector. The three-dimensional surface of the target object is then generated from the recorded image sequence.

The surfaceCONTROL 3D 3500 sensor operates on the principle of optical triangulation based on fringe projection, which allows direct 3D measurement of components to be performed. Using a matrix projector, a sequence of patterns is projected onto the surface of the target object. The light from the patterns is viewed and recorded by two cameras either side of the projector. The three-dimensional surface of the target object is then generated from the recorded image sequence.The surfaceCONTROL 3D 3500 is available in two models, each offering a different measuring area and depth of field. Both models are fully integrated industrial sensors that are protected to IP67 with passive cooling (active cooling is available for higher operating temperatures).

The sensor is suitable for a wide range of applications, including: 3D measurement of high-precision mechanical parts; width, tilt angle and position measurement of rivets; surface defect detection; flatness inspection of circuit boards; planarity inspection of unpopulated PCB substrates; detection and evaluation of breaks on clutch discs; completeness check of electronic components on fitted PCBs; 3D text recognition of embossments that cannot be solved using 2D image processing due to lack of contrast; inspection of height and thickness of adhesive beading on smartphone shells; and determination of shape deviation defects on injection moulded parts.

The surfaceCONTROL 3D supports the very latest GigE Vision and GenICam standards for easy integration into third-party image processing software. A comprehensive software development kit (SDK) is also provided that allows customers to develop their own analysis software.

Also included in the scope of supply is Micro-Epsilon’s 3D View software, which offers a convenient user interface for surfaceCONTROL sensors. The software allows for fast commissioning and evaluation of the sensor, set-up and optimisation of parameters and ensures the correct positioning of the measuring object and sensor. The software can also be used to start data acquisition. It enables 3D data to be visualised and exports this in different file formats (ASCII, CSV, STL and PLY) for further processing. The software is particularly helpful to systems integrators, as it allows them to access all GenICam parameters and simplifies software integration. For in-line applications, the display of the measurement duration allows conclusions to be drawn about the process cycle time.

www.micro-epsilon.co.uk