Software offers true digital continuity with a central interface

13/09/2021

Predictive maintenance is one of the big promises emerging from Industry 4.0 developments, but it can be difficult to achieve, due to the lack of data synchronisation and continuity between inspection results and reporting. Or, to put it differently, there is no use for big data without connecting different sources in a meaningful way. The risk is that asset owners and operators might face a lack of critical information related to the asset’s health status.

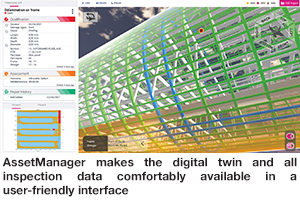

Predictive maintenance is one of the big promises emerging from Industry 4.0 developments, but it can be difficult to achieve, due to the lack of data synchronisation and continuity between inspection results and reporting. Or, to put it differently, there is no use for big data without connecting different sources in a meaningful way. The risk is that asset owners and operators might face a lack of critical information related to the asset’s health status.The solution is a central interface that congregates and links all data related to an asset. Testia’s software AssetManager provides real-time access to technical and visual data of damage and repairs on a digital 3D mock-up: the asset’s digital twin. This powerful tool helps to increase efficiency, savings and control of all manufacturing and maintenance activities for diverse asset portfolios.

It is claimed the improvements are immense for operators, engineers and quality managers: no more hassle with isolated data sources and reporting duplications, thanks to a one-point entry and user-friendly interface. Imagine having all of the following available in a single, central hub: recording, assessing, monitoring and reporting of damage, inspections and repairs precisely on any asset digital twin, as well as access to many manuals at the latest revision.

Through the software’s fully digital continuity and harmonised workflow, it is possible to achieve truly agile decision-making for any asset with an available digital mock-up. AssetManager connects team members transnationally and across all functions through its cloud-based functionality. With real-time data access and instant decision-making, inspectors are said to be optimally prepared for all time-critical operations such as hot-spots, health status checks, repairs, inspection work and much more.

Through the software’s fully digital continuity and harmonised workflow, it is possible to achieve truly agile decision-making for any asset with an available digital mock-up. AssetManager connects team members transnationally and across all functions through its cloud-based functionality. With real-time data access and instant decision-making, inspectors are said to be optimally prepared for all time-critical operations such as hot-spots, health status checks, repairs, inspection work and much more.www.testia.com