Midas installs new ten-axis ultrasonic inspection system

22/04/2009

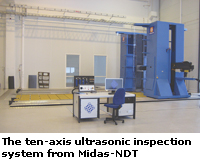

Midas-NDT has installed a new C-GIS2 type ten-axis ultrasonic inspection system at an aerospace customer in Norway. The system will be used for the inspection of complex shaped aerospace components manufactured from composite materials.

Midas-NDT has installed a new C-GIS2 type ten-axis ultrasonic inspection system at an aerospace customer in Norway. The system will be used for the inspection of complex shaped aerospace components manufactured from composite materials.The system was fully manufactured at Midas-NDT in England before disassembly and delivery to the customer in Norway where full installation, commissioning and training was carried out as part of a turn-key operation.

The combination of all ten axes of movement allows the system to follow any component shape in a scanning envelope of 8000 mm by 2500 mm by 1200 mm and a full video presentation of system movement can be seen on the company website at www.midas-ndt.co.uk

Complex curved shapes can be easily programmed using simple teach-and-learn techniques. This style of system is also capable of importing CATIA shape information and processing all necessary scanning parameters from the information to create a scan pattern. Any scan parameters can be stored and recalled by the operator using the given scan shape name. This allows a customer to carry out the inspection of multiple components of a similar shape.

This installation is the second C-GIS2 system to be supplied in the last twelve months following a recent installation in Burnley, England, of a similar system.