Oceaneering invests in M-Skip solution for non-destructive inspection of components

03/08/2007

Leading inspection provider will use M-Skip to examine corrosion levels of inaccessible plant componentsESR Technology, one of the UK's leading engineering, safety and risk consultancies, has announced that it has won a contract to license its M-SkipTM solution to Oceaneering, a global provider of non-destructive testing and inspection services to the oil, gas and power industries.

M-Skip enables owner operators to non-destructively examine plant components rendered inaccessible by obstructions. The corrosion levels of pipes, risers and vessels in oil and gas, chemical and process facilities can be measured without the need to move obstructions such as supports, clamps and saddles which can prove costly and time consuming.

M-Skip was initially developed within the HOIS joint industry project for improved NDT in the oil and gas industry. HOIS is managed by ESR Technology and has recently benefited from a large increase in membership which now stands at twenty one. This includes many of the world's largest oil and gas multinationals, as well as leading inspection service and vendor com

panies.

panies.ESR Technology has developed advanced analysis software for the interpretation of data obtained using the M-Skip ultrasonic inspection technique. This software has been implemented as part of ESR Technology's NTPLOT Windows software package for the display, processing and analysis of NDT data.

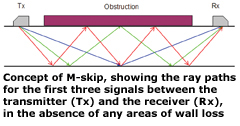

M-Skip is a new variant of the time-of-flight-diffraction (TOFD) inspection technique and is based on angled shear wave probes, separated by the distances required to inspect wider pipe supports and clamps. The signals traveling between the probes then typically experience many reflections, or skips, between the front and back component surfaces. Measurements of the arrival times of these skip signals can be used to establish the average wall thickness along the line of sight between the probes.

The presence of wall-loss flaws on both component surfaces can be detected by either loss of the skip signals, or by arc-like signals generated by scattering from the 'tops' of the flaws. Measurements of the time difference between the flaw signals and the associated skip signals provide quantitative information on the through-wall extent of the flaws and therefore the corrosion levels of the component.

"The development of M-Skip within the HOIS programme is an excellent example of successful shared cost research and development with rapid progress from initial laboratory tests, through independently validated blind trials to successful deployment for in-service applications in an offshore environment," said Steve Burch, Manager of ESR Technology's NDT group.

"M-Skip is an important addition to the family of ultrasonic techniques that help with the integrity management of inaccessible regions of critical structures," added Geoff Eckold, ESR Technology's Engineering Director. "Oceaneering has a strong reputation in the industry for its practical application of cutting edge inspection techniques and we know that M-Skip will support its excellent work in this area."

www.esrtechnology.com