Festo’s AI cuts downtime by predicting pneumatic wear

23/12/2025

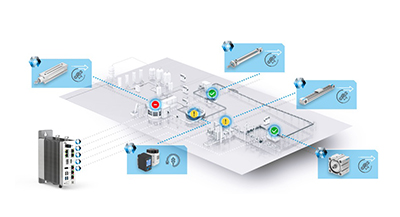

Festo has launched its artificial intelligence (AI)-enabled monitoring and predictive maintenance technology, Festo AX Motion Insights Pneumatic. This technology offers an affordable, user-friendly way to avoid expensive unplanned machine downtime by monitoring pneumatic cylinders for wear and anomalies. The company claims that this AI-driven industrial app improves operational reliability, efficiency and profitability.The system applies AI to spot abnormal behaviour in pneumatic drives and cylinders without requiring extra sensors. It reports a ‘health score’ as a ‘risk of failure’ indicator for each cylinder. Connectivity is provided via a programmable logic controller (PLC) function block. The solution supports actuators from multiple manufacturers and includes specific connectivity details for Siemens, Rockwell and Beckhoff controllers.

| ||

| The system applies AI to spot abnormal behaviour in pneumatic drives and cylinders without requiring extra sensors |

Motion Insights Pneumatic lets maintenance teams plan tasks ahead of time, greatly lowering the chance of unexpected downtime. The platform supports on-premises deployment so end-users retain full control over their data and how the system is run. As an open system, it works with both Festo and third-party components. The AX platform emphasises ease of use and smooth integration, making it easier for customers to adopt the AI- and data-driven solutions of today and advance their digital transformation.

A key component of Motion Insights Pneumatic is its integration with Festo’s Smartenance maintenance management system. Motion Insights Pneumatic identifies when maintenance is required and Smartenance organises and tracks the resulting tasks. Together they form a unified, end-to-end workflow that ensures predictive insights are both visible and acted upon efficiently.

Motion Insights Pneumatic installs and operates simply. The app’s ‘plug-and-play’ design, intuitive interface and standardised AI models lower the barrier to entry. This benefits original equipment manufacturers (OEMs) and end-users beginning their digital journeys by delivering AI advantages without deep data-science expertise. Both OEMs and end-users can download the app, install it and integrate it themselves.

Festo AX Motion Insights Pneumatic complements the Festo AX Motion Insights Electric app, which targets electric components, and Festo AX Data Access, which exposes operational technology (OT) data for information technology (IT) analysis. Customers can deploy the apps individually or together. CODI Manufacturing in Littleton, Colorado, USA, recently installed all three on a compact gantry palletiser to maximise uptime and operational efficiency insights for its customers.

The apps deploy on-premises using standard hardware and container technology such as Docker. Containerisation enables flexible deployment across industrial PCs, virtual machines, servers and edge devices. Insights Electric and Pneumatic are available by subscription. Data Access is sold under a perpetual license.

Customers choose a license package based on how many cylinders they want to monitor. Unlike competitors that may provide a single software tool, Festo AX apps integrate into a complete, one-stop automation solution that includes electrical and pneumatic components, simplifying integration and providing a single support contact.