Why eddy current sensors are replacing inductive sensors and switches

03/02/2022

Both eddy current sensors and inductive switches and displacement sensors have their respective advantages when measuring the position and displacement of objects in harsh environments. However, recent advances in eddy current sensor design, integration, packaging and overall cost reduction have made these sensors a much more attractive option, particularly where high linearity, high-speed measurements and high resolution are critical requirements. Glenn Wedgbrow, Business Development Manager at Micro-Epsilon UK, explains…In order to appreciate the inherent advantages of eddy current sensors relative to inductive switches and displacement sensors, it is important to first understand the operating principles behind these approaches.

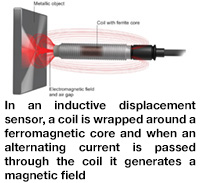

The classic inductive displacement sensor comprises a coil that is wound around a ferromagnetic core.

When excited by an alternating current from an oscillator-based driver circuit, the coil generates a magnetic field that is concentrated around the core. The lines of flux interact with the target conductor as it approaches, creating eddy currents that are the reverse of the initial excitation current and have the effect of reducing the voltage across the oscillator. These variations in voltage due to the change in air gap distance are detected and converted to an analogue output signal, such as a 4-20 mA loop, and then processed upstream to determine displacement.

A proximity sensor, also called a proximity switch, involves a simplified application of the principles behind the induction effect, detecting only whether or not an object (the conductive target) is present. A comparator (Schmitt trigger) detects the drop in voltage and sends a signal to an amplifier.

This in turn switches the output in a binary fashion. The output can be normally open (NO) or normally closed (NC), depending on the user’s choice of configuration.

Because of the ferromagnetic core in an inductive displacement sensor, the output is non-linear and so it needs to be linearised, either in the sensor electronics or mathematically using polynomials in the plant or machine control system.

Along with non-linearity, another downside of using a ferromagnetic core relates to the ‘iron losses’ due to the core itself absorbing the magnetic field. These losses increase with frequency, to the extent that an inductive displacement sensor maxes out at around 50 measurements per second.

A third problem with inductive displacement sensors is poor tolerance to wide temperature variations because of the high thermal coefficient of expansion of the ferrite core material. This wide variation makes temperature compensation very difficult, usually resulting in a large thermal drift for inductive displacement sensors.

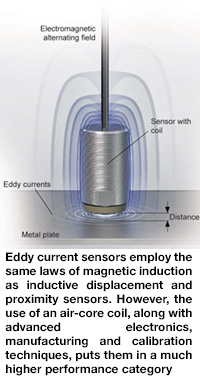

To overcome these limitations, eddy current sensors, which represent a certain class of inductive displacement sensor, have been developed. Rather than a ferrite core, these sensors use an air-core coil.

While the operating principles of the eddy current sensor are in line with Faraday’s Law, it is the effect of the eddy currents on the impedance of the coil that is measured rather than the voltage change of the oscillator. The controller calculates the impedance by looking at the change in the amplitude and phase position of the sensor coil.

While all the sensors mentioned are able to detect targets such as metals and ferromagnetic and non-ferromagnetic materials in harsh non-contact environments, the architecture of the eddy current sensor, as well as the advanced electronics, manufacturing and calibration techniques employed, put it in a much higher category in terms of performance.

These performance characteristics can be broken down into two categories: inherent characteristics and characteristics resulting from product design, manufacturing and calibration. The three most exciting inherent features are the very high measurement frequency of up to 5 kHz, high resolution down to 0.5 µm and high linearity and temperature stability.

Because of the use of an air-core coil versus a ferrite core, an alternating current of up to 1 MHz can be used, although the electronics in devices such as the eddyNCDT 3001 and the NCDT 3005 provide measurement frequencies of 5 kHz. This is still 10× that of their inductive displacement counterparts, which typically top out at 50 Hz (translating to 50 measurements per second). Higher-end Micro-Epsilon eddy current sensors can reach 100 kHz.

In terms of linearity and temperature, the air-core coil does not have to deal with the flux losses or compensate for the thermal expansion of a ferrite core, so it has a 10× improvement in linearity. This linearity is also the result of Micro-Epsilon’s manufacturing and calibration process, whereby the coil is placed in an oven and cycled between −20°C and +60°C. The changes in the material are stored in the calibration set-up in the sensor and used to compensate for temperature fluctuations.

While some inductive displacement sensors also have compensation built into the sensor, it is typically limited to ±3-5% of the full-scale output (FSO). Eddy current sensors provide compensation for the full measurement channel (±0.025% FSO). It is also important to note that eddy current sensors are calibrated to the target material at the factory for maximum accuracy, which puts a higher premium on these devices.

Both proximity and inductive displacement sensors can be housed in solid metal (food-compatible high-resistance grades). The operating principle of eddy current sensors means they must use a non-metallic cap. Despite this, Micro-Epsilon eddy current sensors are still certified to IP67. In addition, the packaging of eddy current sensors has been advancing rapidly, with the electronics being integrated into the device.

Most significantly, the eddyNCDT 3001 product line signifies a new class of eddy current sensor that comes in an M12 housing with both the integrated controller and signal conditioning unit. This makes these sensors much more amenable to standard mechanical formats and requirements, as well as making them a more attractive replacement option for inductive displacement sensors.

The new eddyNCDT 3005 from Micro-Epsilon has separate compact electronics, which enables many different sensor measuring ranges to be packaged with compact ‘in-cable’ M12 electronics. Other characteristics include the ability to withstand up to 300 bar of ambient pressure. Also, the voltage output is the same as that of inductive displacement sensors, covering the full 0.5 V to 9.5 V, making them fully comparable on a 1:1 basis.

The high cut-off frequency of eddy current sensors enables metrological detection of distance values, even in high-speed processes such as the operation of machine tools and crankshafts. IP67 protection ensures they can also be used in harsh industrial environments and dirt or humidity will not influence the measurement result. A classic example is monitoring the lubricating gap in a combustion engine.

Custom sensor designs for specific needs are possible, including specific target object calibrations, mounting options, individual cable lengths and modified measuring ranges, as well as pressure tolerance to 2000 bar.

When using eddyNCDT sensors, care must be taken to ensure they are placed as close as possible to 90° relative to the target surface in order to achieve the highest resolution and measurement accuracy.

Sometimes, an exact right-angle mounting of the sensor to the target is difficult or impossible. In such cases, the measured values will deviate marginally from those acquired at a right angle, so the sensor supplier’s graphs can be used to factor in the effect of a tilted sensor. For example, with a 4 mm sensor and an aluminium target, an inclination of ±4° can be accepted and neglected in most applications. For placement, note that the use of an air core means that the distance from the sensor head to the target should be 4 mm or less.

www.micro-epsilon.co.uk