ABB modernises variable speed drives

13/01/2026

ABB has launched a new modernisation service for its variable speed drives (VSDs), embedding Samotics-powered electrical signature analysis (ESA) technology into legacy drives.

The announcement was made at the Abu Dhabi International Petroleum Exhibition & Conference (ADIPEC 2025), which was held from 3-6 November 2025 in Abu Dhabi, United Arab Emirates, offering industrial operators real-time insights into the health of their powertrain systems.

By integrating ESA technology, ABB transforms VSDs into intelligent sensors capable of monitoring motors, pumps, fans, mixers and conveyors. The drives can now detect changes in operating behaviour, such as:

- bearing wear or damage;

- coupling or gear misalignment; and

- pump cavitation.

“This leap forward in the modernisation of legacy drives promises to be a catalyst for the digital transformation of industry,” said Oswald Deuchar, Global Head of Modernisation Services at ABB Motion Services.

“It enables quick, seamless and cost-efficient adoption of ESA technology for enhanced uptime, with full support from ABB’s global expert network.”

| ||

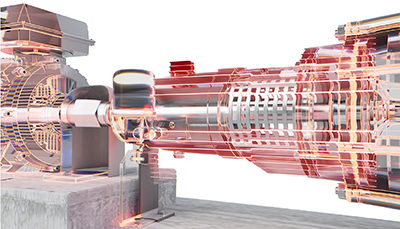

| ESA-enabled drives collect electrical data directly from the powertrain Image courtesy of ABB |

Embedding ESA directly into drives allows the technology to function in hard-to-reach or harsh conditions, including submerged pumps and areas with extreme heat or toxicity.

“This is a key step towards autonomous, self-optimising operations that are at the heart of the factory of the future,” added Simon Jagers, Founder and Co-CEO of Samotics.

ESA-enabled drives collect electrical data directly from the powertrain. Through Samotics analytics and ABB’s global support network, this data is converted into real-time, actionable insights, providing recommendations that maximise uptime, optimise maintenance resources and improve overall reliability.

The modernisation service initially targets ABB’s low-voltage ACS 600 and ACS 800 cabinet-built drives, incorporating TÜV-certified cybersecurity measures to meet evolving industrial requirements.

As part of the ABB Ability condition monitoring suite, ESA complements the vibration analysis capabilities of ABB, offering users a complete view of powertrain health. Together, these solutions ensure early fault detection, clearer service actions and maximised reliability across both low- and high-speed systems.