Computed radiography reveals hidden details in historical artworks

26/01/2026

The Dresden State Art Collections (Staatliche Kunstsammlungen Dresden (SKD)) consists of 15 museums, which are claimed to be amongst the most important in the world. Together with four other institutions, it represents a thematic diversity that is unique in its kind internationally. One of its central tasks is the preservation and research of art objects made from a wide variety of materials. | ||

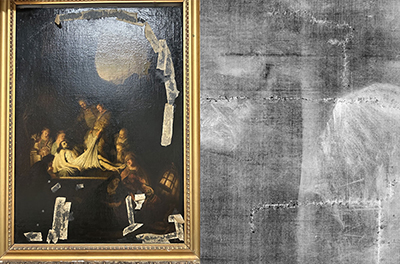

| Rembrandt, The Entombment of Christ (copy); visible canvas structure with large tear, which was invisible under repairs Image courtesy of Laura Princzes, SKD |

Modern digital radiography makes it possible to dive deep into the history of artworks and reveal previously hidden details. Over the past six months, 11 different objects have been examined, including canvas and panel paintings and a rhinoceros horn cup. By using computed radiography (CR) technology from Dürr NDT, the analysis was carried out with impressive time savings: instead of half a day for four analogue X-ray films (30 × 40 cm), the duration was reduced to half the time. In addition, the use of chemical development processes was eliminated, which reduces costs while protecting both the environment and the health of the employees.

A key advantage of digital imaging plate technology is its flexibility and extreme thinness. This allows even fragile and unusually shaped objects to be examined with precision. Using image stitching in combination with a panorama program, high-resolution X-ray images in TIF format were created, showing even the finest details of the artworks.

| ||

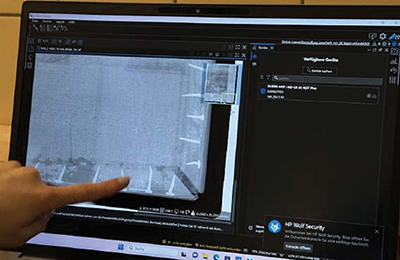

| The system offers preset parameters for examining artworks to optimise the imaging process |

The investigations were primarily initiated by SKD, including requests from the Green Vault, the Albertinum and the Old Masters Picture Gallery. Computed radiography was used to analyse works of art, including copies of Rembrandt’s painting The Entombment of Christ. This resulted in valuable insights into the creative process behind the works. By comparing temporal characteristics, it is possible to determine whether certain details were added later. These characteristics include the quality of the canvas, painting techniques, materials and paint. The type of canvas in particular can be determined and compared really well using X-ray images.

As a preliminary step to X-raying, infrared reflectography was used to make underdrawings visible. The grazing light technique was also used to reveal relief-like elevations or structures. While the identification of forgeries was not the main objective of the investigations, X-ray analysis revealed evidence of later alterations and retouching.

Thanks to digital radiography, detailed conclusions can be drawn about the structure and restoration history of canvases. Previously hidden damage has become visible, including tears and colour loss, where the painting has been smoothed by sewing or filling. This is invaluable, especially for museums and galleries, as many works have to be taken out of storage and restored before an exhibition.

| ||

| Digital radiography reveals details about the structure and type of canvas |

In the case of wooden panels, X-ray analysis provides insights into the joining techniques used for the individual boards. Without X-rays, it would not be possible to determine whether the panels were simply glued or joined with dowels. It was also found that the joints varied by only a few millimetres, which is impressive evidence of the high precision with which the panels were manufactured.

High-resolution imaging plates (HD-IP 30 × 40 cm) were used for the examinations in combination with the CR scanner HD-CR 35 NDT and the X-ray inspection software D-Tect X. The user-friendly system is said to be easy to operate, while preset parameters for artworks optimise the processes. At the same time, the system offers extensive export options for further analysis and documentation.

Dürr NDT’s digital X-ray images have proven to be just as accurate as traditional film images and offer significant advantages in terms of speed, environmental friendliness and detail accuracy, it is claimed. CR technology thus makes a significant contribution to the scientific examination and preservation of valuable art objects.

Dürr NDT is a German manufacturer of innovative digital industrial X-ray inspection systems and equipment for non-destructive testing (NDT).

www.duerr-ndt.com