A better perspective with Yxlon HDR technology

09/07/2012

The firm Martinrea Honsel Germany GmbH numbers among the main suppliers of renowned national and international automobile manufacturers. For years, the company has been setting standards in inspecting the quality of cast products. X-ray inspection bears a particular importance towards accomplishing this.In its capacity as a leading provider of industrial X-ray and CT

systems, Yxlon International fosters an intensive, long-standing partnership with Martinrea Honsel. This is displayed especially in the procurement of new systems, as well as in the continuous maintenance and upkeep of the existing X-ray systems in place.

systems, Yxlon International fosters an intensive, long-standing partnership with Martinrea Honsel. This is displayed especially in the procurement of new systems, as well as in the continuous maintenance and upkeep of the existing X-ray systems in place.The mutual drafting of solutions towards quality optimisation is an integral element of this successful cooperation. This is equally the case for inspecting a significant cast part. The X-ray cabinet from the Y.MU2000 line being used to do this is currently equipped with analogue image analysis technology. During inspection of a certain region of the part, it quickly became clear that the physical limits of image intensifier technology had been reached.

Thanks to the excellent work together on a partnership level, the problem with this crucial area was able to be resolved impressively within the course of a live demonstration using HDR technology from Yxlon.

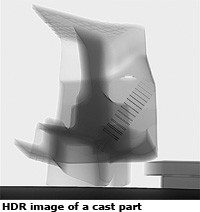

Thanks to the excellent work together on a partnership level, the problem with this crucial area was able to be resolved impressively within the course of a live demonstration using HDR technology from Yxlon. HDR – highly dynamic radioscopy – designates a procedure in which an irradiated inspection item seems ‘as if made of glass’ in a low-noise live image, due to a digital flat-panel detector and a special image processing filter.

As a result of this glass-like depiction, the inspection item can be tested at a glance, without having to adjust the X-ray parameters for thick and thin regions. Flaws become visible right away, and are thus detected with certainty.

Martinrea Honsel decided right then and there to refit the X-ray cabinet with the digital HDR image analysis and evaluation technology from Yxlon. The decision brings the system to a status exhibiting the most up-to-date technology.

With the apparent advantages obtained thereby, such as high detail detectability, high inspection certainty and inspection speed, detectability of all flaws in the live image at a glance and definition of the spatial position and shape of defects, Martinrea Honsel Germany GmbH is going to continue to set standards in inspecting quality and continue to meet its customers’ high-quality specifications in all respects.

www.yxlon.de