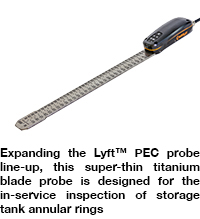

Eddyfi launches tank floor pulsed eddy current (PEC) probe

21/11/2016

As a world leader in advanced electromagnetic inspection technologies, Eddyfi has launched the tank floor PEC probe. The probe was developed for the in-service inspection of storage tank annular rings and Eddyfi claims that no other inspection technique can currently achieve this without emptying tanks.

With its super-thin 4.8 mm (0.2 in) titanium blade, the probe can slide up to 400 mm (16 in) under tank floor edges to assess the remaining wall thickness of this critical region exposed to corrosion. This latest addition to the Lyft™ solution makes it possible to include storage tank annular rings in asset integrity management (AIM) programmes, minimising the risks of unforeseen and potentially hazardous failures.

Eddyfi used all of its know-how to develop this probe and included support for features customers already appreciate from its existing standard Lyft probes, for example the built-in remote controls and status LEDs for efficient one-person operation. The tank floor probe’s bottom surface is also magnetically shielded, maximising sensitivity for optimal component analysis and protection against signal distortion from potential disruptive ferromagnetic structures. Finally, the probe’s titanium blade is designed to withstand harsh field conditions.

“This new addition to the Lyft family further demonstrates our commitment to pulsed eddy current technology and how we will continue to tackle new applications,” said Martin Turgeon, Instruments and PEC Product Manager at Eddyfi. “One of the main advantages of pulsed eddy current is its ability to be used as an in-service screening tool to assess general corrosion, something this new probe does perfectly.”

www.eddyfi.com