WCCM 2017

13-16 June 2017, ILEC Conference Centre, London

The International Society for Condition Monitoring (ISCM) and the

British Institute of Non-Destructive Testing (BINDT) are delighted to hold this global event. This congress is of major significance, being the first world event in its field. Ownership and overall control of the event rests with the ISCM and this premier event is being organised in the United Kingdom by BINDT in collaboration with almost all condition monitoring and NDT societies worldwide. This combination of efforts will create one of the largest events of its kind at a truly international level. The event will provide you with a unique opportunity to network with leading academics and industrialists from all over the world in the field of condition monitoring and related areas.

British Institute of Non-Destructive Testing (BINDT) are delighted to hold this global event. This congress is of major significance, being the first world event in its field. Ownership and overall control of the event rests with the ISCM and this premier event is being organised in the United Kingdom by BINDT in collaboration with almost all condition monitoring and NDT societies worldwide. This combination of efforts will create one of the largest events of its kind at a truly international level. The event will provide you with a unique opportunity to network with leading academics and industrialists from all over the world in the field of condition monitoring and related areas.The congress will embrace all aspects of condition monitoring and related areas and papers are invited from individual contributors, although it is expected that the majority of papers will be submitted from delegates who are members of the national condition monitoring and NDT societies, many of which are already members of the ISCM. The national societies are asked to encourage their members to actively participate in the event. Presenters of papers that are members of the national societies are welcome to attend the congress at discounted ‘Member’ rates.

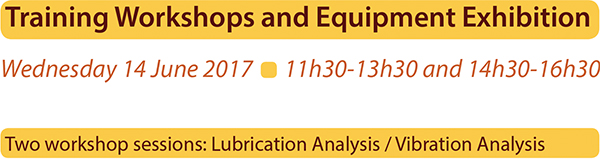

Each two-hour workshop will provide an industry-focused basic knowledge of the subject

Each two-hour workshop will provide an industry-focused basic knowledge of the subject One hour of basic theory and one hour of industrial applications

One hour of basic theory and one hour of industrial applications Workshop leaders are trainers and experts in their field

Workshop leaders are trainers and experts in their field The subject is taught from a basic level, no prior subject knowledge is necessary

The subject is taught from a basic level, no prior subject knowledge is necessary Ideal preparation for PCN Level 1 courses

Ideal preparation for PCN Level 1 courses Find out how basic CM technology can solve your everyday problems

Find out how basic CM technology can solve your everyday problems Exhibition of equipment covering both methods

Exhibition of equipment covering both methods  See equipment demonstrated by the tutors at the exhibition

See equipment demonstrated by the tutors at the exhibition

Lubrication Analysis – 11h30-13h30

Steve Greenfield, Eaton Aerospace

Steve brings 30 years’ experience of oil debris monitoring and analysis technology, focusing on real-time online systems for aerospace and general industry.

Vibration Analysis – 14h30-16h30

Dean Whittle, Training & Reliability Manager, Reliability Maintenance Solutions Ltd, MSc Condition Monitoring

Dean has over 31 years’ experience in electromechanical engineering and during the past 20 years has been committed to implementing plant reliability and condition monitoring improvement programmes throughout industry.

CPD points apply.

| Monday 12 June | ||||||

| 16.00 onwards | Registration – Room: ILEC Conference Centre Foyer | |||||

| 18.00-20.00 | Welcome Buffet – Room: London 9 | |||||

| 20.00-22.00 | Meeting of the ISCM Management Committee – Room: Hyde Park (first floor) | |||||

| Tuesday 13 June | |||||||

| 08.00 onwards | Registration – Room: ILEC Conference Centre Foyer | ||||||

| 08.45-09.15 | Opening Ceremony – Professor L Gelman, C Bull and C Sinclair | ||||||

| 09.15-09.45 | Plenary Keynote Lecture [101] History and future trends of machine condition monitoring – a personal perspective Professor R B Randall, University of New South Wales Chair: Professor L Gelman Room: London 7 and 8 | ||||||

| 09.45-10.00 | An Introduction to Condition Monitoring and Diagnostic Technologies – Promotion of CM Book Professor A Hope Chair: Professor L Gelman Room: London 7 and 8 | ||||||

| 10.00-10.30 | Tea and Coffee Break – Room: London 9 | ||||||

| Session 1A – Condition monitoring methods and technologies Chair: Dr T Ciszewski Room: London 7 and 8 |

Session 1B – Condition monitoring methods and technologies Chair: Professor A Lucifredi Room: London 1 |

Session 1C – Trained structures and statistical methods in condition monitoring Chair: Professor L Kuravsky Room: London 2 |

Session 1D – Condition monitoring methods and technologies Chair: Professor A Hope Room: London 3 |

Session 1E – Vibration condition monitoring methods and technologies Chair: Dr S Ganeriwala Room: London 4 |

Session 1F – Signal processing: Identification, fault diagnosis and reliability for complex system monitoring – Part 1 Chair: Dr N Martin Room: London 5 | ||

| 10.30-10.50 | [102] Novel condition monitoring of induction motor bearings via motor current signature analysis T Ciszewski1, A Dzwonkowski1, L Swędrowski1 and L Gelman2 1Gdańsk University of Technology 2Cranfield University | [103] The diagnosis and prognosis of analogue and digital electronics using biologically-inspired neural networks and artificial intelligence B D McCartney | [104] Applied multi-agent system to study the behaviour of operators of complex technical systems L S Kuravsky, S I Popkov and S L Artemenkov Moscow State University of Psychology and Education | [105] Research on image comparison processing technology in electrical equipment infrared thermography detection Y Yu1,2, G Shen1,2, C Ye1 and Y Li1 1China Special Equipment Inspection and Research Institute (CSEI) 2AKLNDE, China | [106] Probe track run-out identification and compensation to benefit machinery diagnostics P Barrowclough GE Oil & Gas | [204] Invited overview presentation Signal processing for condition monitoring – exciting challenges ahead Dr N Martin |

|

| 10.50-11.10 | [108] Condition monitoring of superconducting magnets M Wołoszyk1, M Ziółko1, M Michna1, L Swędrowski1, A Wilk1 and P Szwangruber2 1Gdańsk University of Technology, Poland 2GSI Helmholtz Centre for Heavy Ion Research, Germany | [109] What is big data? Nothing new, just true all-encompassing condition monitoring of your rotating plant, which is beneficial as a management and risk reduction aid C J P Fryer Sulzer Dowding & Mills | [110] On the approach to adaptive psychological testing of CM personnel L S Kuravsky, S L Artemenkov and G A Yuryev Moscow State University of Psychology and Education | [111] Comparative assessment of manual and automated fault detection methods for railcar air brakes D Juhaszova and M Lipsett University of Alberta, Canada | [112] Using cepstrum information to detect gearbox faults in wind turbine planetary stage gearboxes K Marhadi and G A Skrimpas Brüel & Kjær Vibro A/S, Nærum, Denmark | [113] Belt looseness monitoring through the analysis of both amplitude and phase components of stator currents A Picot1, E Fournier2, C Filleau1,2, J Regnier1, E Mouni2 and P Maussion1 1LAPLACE, Université de Toulouse 2Leroy Somer |

|

| 11.10-11.30 | [114] Multi-parameter modular single-platform monitoring system for large motors and generators B Fruth Quartzteq GmbH, Switzerland | [115] Deeper insight into railway switch condition nowcasting B Dutschk1, J C Groos2, E Hadzic3 and T Böhm4 1Karlsruhe Institute of Technology (KIT), Germany 2German Aerospace Center (DLR) – Institute of Flight Systems 3Strukton Rail Netherlands, Utrecht 419055 Schwerin, Germany | [122] On the problem of detecting abrupt changes in the time histories of diagnostic symptoms T Gałka Institute of Power Engineering, Poland | [117] Location and quantitative evaluation of impact fatigue defects in metallic components with eddy current thermography S Yang, L Liu and B Bahrami Mianrood School of Manufacturing Science and Engineering, Sichuan University | [118] Wind turbine gearbox fault prediction algorithm based on feature subspace P Yubin, R Hong, J Chen and H Wang Nanjing University of Technology | [119] Rotating machine speed estimation using vibration statistical approach M Eltabach1 and G Govaert2 1Senlis, Cetim 2Sorbonne Universitiés |

|

| 11.30-12.00 | Tea and Coffee Break – Room: London 9 – Sponsored by SpectraQuest Inc | ||||||

| 12.00-12.20 | [120] Early detection of inter-turn stator winding short of an induction motor using an online frequency response method K Y See and S B Rathnayaka SMRT-NTU Smart Urban Rail Corporate Laboratory, Nanyang Technological University, Singapore | [121] Advanced condition monitoring of electric submersible pumps (ESPs) F J Quail Aramco Overseas Company UK Ltd | [128] Reliability

criteria and monitoring of the technical condition of powerful turbine

units with use of static and dynamic forces in support of shaft lines A I Kumenko, A V Timin, N Y Kuzminykh DYNAMICS SPC | [123] Influence of instrument channel uncertainties on monitoring systems P Crubellier Comisión Nacional de Energía Atómica THIS PAPER HAS BEEN CANCELLED AFTER THE PRINTING OF THE PROGRAMME | [124] A wireless system for conducting remote vibration monitoring using a remotely-operated deployment robot M G Lipsett, N A Olmedo and B T Tesfay University of Alberta, Canada | [125] The application of the cyclic coherence for distributed planet fault detection in planetary gears D Abboud1, M Elbadaoui1,2, S Becquerelle3 and M Lalmi3 1Safran Tech, France 2Université de Lyon, France 3Safran Transmission Systems |

|

| 12.20-12.40 | [126] Turbine generator stator part temperature monitoring based on KDE-PCA model L Jun1, Q Fang1 and W Xin2 1Shanghai Electric Power Generation Group 2Xi'an Jiaotong University | [127] Data-driven prognostics M von Plate Cassantec AG Presented by M Zvyagina | [134] Hydroelastic oscillations fuel assembly in water and liquid metal coolant V D Sizarev Joint Stock Company NA | [129] Monitoring gearbox oil viscosity by means of motor current signal analysis P V Vuuren1, F Gu2, A D Ball2 and Y Xu2 1North-West University, South Africa 2Centre for Efficiency and Performance Engineering, University of Huddersfield | [130] Vibration analysis of wind turbines D Whittle RMS Ltd | [131] Cepstral removal of resonance effects to improve the use of traditional gear diagnostic indicators under variable speed W A Smith, R B Randall, C Hu and Z Peng University of New South Wales, Australia |

|

| 12.40-13.00 | [132] Fault detection of bearing defects for ball screw-based electromechanical actuators M A A Ismail and J Windelberg German Aerospace Center (DLR) – Institute of Flight Systems | [133] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [116] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [135] Comparison of lock-in and pulse compression thermal imaging techniques for non-destructive defect detection D Roy1 and S Tuli2 1Centre for Applied Research in Electronics, India 2Bennett University, India | [136] From condition monitoring to condition/reliability improvement D Whittle RMS Ltd | [137] Non-uniform (Re) sampling for optical encoders F Bonnardot and J Al Fallah Université de Lyon, LASPI, France |

|

| 13.00-14.00 | Lunch – Room: London 9 |

||||||

| 13.30-15.30 | ICNDT Working Group Meeting – Room: Hyde Park (first floor) | ||||||

| 14.00-14.30 | Plenary Keynote Lecture [138] Aero engine health monitoring and diagnostics for smart control and fleet management within a global environment Dr P Laskaridis and Professor P Pilidis, UK Chair: Professor L Gelman Room: London 7 and 8 | ||||||

| | Session 2A – Condition monitoring and NDT methods and technologies Chair: Professor T-H Gan Room: London 7 and 8 | Session 2B – Vibration condition monitoring methods and technologies Chair: Professor V Kostyukov Room: London 1 | Session 2C – Trained structures and statistical methods in condition monitoring Chair: Professor L Kuravsky Room: London 2 | Session 2D – Signal processing: Identification, fault diagnosis and reliability for complex system monitoring – Part 2 Chair: Dr N Martin Room: London 3 | Session 2E – Vibration condition monitoring methods and technologies Chair: Dr H Chandra Room: London 4 | Session 2F – Signal processing for condition monitoring and NDT Chair: Dr K C Gryllias Room: London 5 |

|

| 14.30-14.50 | [139] Ultrasonic probe using advanced piezoelectric single-crystal gallium orthophosphate for NDT at 580°C M Kostan1, C Nageswaran2, T–H Gan1,2 and J Kanfoud1 1Brunel University London 2TWI Ltd | [140] Improving reliability of vibration spectrum identification without increasing sampling rate using a spectral interpolation algorithm V N Kostyukov and S N Boychenko DYNAMICS SPC | [141] Balancing of shafting of a test-rig using shaft displacement sensors A I Kumenko, N Y Kuz'minykh and A V Timin DYNAMICS SPC | [142] How a bearing defect modifies vibration and IAS of a rotating machine: a phenomenological overview based on experiments and models D Rémond, J-L Gomez and A Bourdon Université de Lyon | [149] Planetary gearbox fault feature extraction based on sparse decomposition under variable speed operation Y Li, K Ding and G He South China University of Technology, China | [144] Measurement of rotor forces acting on a rotor with use of magnetic bearings NTIS: new technologies for the information society – cybernetics K Kalista NTIS (New Technologies for the Information Society) – Cybernetics |

|

| 14.50-15.10 | [145] Modelling and measurement of guided wave propagation in Denso tape-coated pipes W Duan1, J Kanfoud1, T-H Gan1,2, M Deere2 and P Mudge2 1Brunel University London 2TWI Ltd, Cambridge | [146] Reducing machine downtime through vibration monitoring analysis: use case of a mechanical press machine and transfer U Martínez-de-Estarrona1, A González-González1, J C Sánchez1, D Seneviratne2 and D Galar1,2 1Tecnalia Research and Innovation, Spain 2Luleå University of Technology, Sweden | [147] On additional requirements to vibration control systems and systems for monitoring the technical state of turbo sets for thermal and nuclear power plants A I Kumenko and N Y Kuz'minykh DYNAMICS SPC | [148] Automatic track and balance of wind turbine rotors M Bertele1, C L Bottasso1, S Cacciola2 and M Domestici3 1Technische Universität, München 2Politecnico di Milano 3University of Perugia | [143] Modelling of experiment of a faulted spur gear pair A Zippo, F Pellicano and M Barbieri University of Modena and Reggio Emilia | [150] Resistant spot welding quality assessment based on novel wavelet analysis with multi-indexes S Chen, N Wu, J Hao, T Sun and L Cui Beijing University of Technology |

|

| 15.10-15.30 | [151] Digital vibration monitoring and risk analysis system for process piping A Angulo TWI | [152] Real-time monitoring on vibration-based diagnostics of reciprocating compressors V N Kostyukov and A P Naumenko DYNAMICS SPC | [153] Impact of static compliance of support and non-linearity of oil film on shafting alignments during monitoring of support misalignments A I Kumenko, N Y Kuz'minykh and A V Timin DYNAMICS SPC | [154] A telemetry monitoring system using the one-class SVM method L Chaari1,2,3, J-Y Tourneret1,2,3, S Fuertes4, G Picart4, A Ferrari5 and C Richard5 1INP-ENSEEIHT, University of Toulouse 2IRIT, Toulouse 3TeSA (Telecommunications for Space and Aeronautics Lab) 4Centre National d’Études Spatiales (CNES) 5University of Nice Sophia Antipolis | [155] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [156] A semi-supervised SVDD-based fault detection method for rolling element bearings K C Gryllias, J Qi, A R Mauricio and P-J Vandenbrande Department of Mechanical Engineering, KU Leuven |

|

| 15.30-16.00 | Tea and Coffee Break – Room: London 9 | ||||||

| 16.00-16.20 | [157] Investigation of the high-temperature performance of ultrasonic guided wave systems for in-service condition monitoring of pipework in thermal power plants A Dhutti1, T-H Gan1, 2, A Mohimi2 and J Kanfoud1 1Brunel University London 2TWI Ltd | [158] Piezoelectric-based wireless vibration characteristic research for rail base of turnout switch rail P Hu1, H Wang1, G Tian1,2, P Wang1, R Guo2, F Qiu3, Q Liu1 and W Wang1 1Nanjing University 2Newcastle University 3University of Electronic Science and Technology of China | [159] Discrepancy signal processing techniques for gearbox condition monitoring applications S Schmidt, P S Heyns and J P de Villiers University of Pretoria | [160] Dynamic factor analysis and predictive diagnosis of critical railway components A Samé1 and G Govaert2 1Université Paris-Est, France 2Heudiasyc, France | [161] A low-power wireless vibration sensing framework for machine health monitoring using a packet loss tolerant approach A Villanueva-Marcocchio1 and B Jones2 1University of Sheffield 2IEEE | [168] Multi-sensory data fusion for real-time welding defect detection: reviews and its application case Z Zhang and G Wen Key Laboratory of Education Ministry for Modern Design and Rotor-Bearing System, The Research Institute of Diagnosis and Cybernetics, Department of Mechanical Engineering, Xi’an Jiaotong University | |

| 16.20-16.40 | [163] Developments in the application of non-intrusive techniques for identifying the condition of high-voltage switchgear and cables J Butler EA Technology Ltd | [164] Diagnosis of rolling bearing defects of fan and root cause analysis H Fan and Z Xiang SKF, China | [165] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [166] Analysis of IAS for condition monitoring by means of a simplified wind turbine dynamic model J L Gomez1,2, I Khelf1,2, A Bourdon11, H Andre3, L Alloin2 and D Remond2 1Université de Lyon 2Engie Green, France 3LASPI – Université de Lyon | [167] Implementation of a null space anomaly detection method on rolling element bearings E Zugasti, U Leturiondo and O Salgado IK4-IKERLAN Technology Research Centre | [174] Thrust bearing monitoring of vertical hydro-turbine generators R Nowicki1 and N Morozov2 1GE Digital, Poland 2GE Digital, Russia |

|

| 16.40-17.00 | [169] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [170] Matching pursuit based on slip-matrix singular value decomposition for rolling bearing fault diagnosis J Xu1,2, F Cong1, S Tong1, N Tang2 and Y Zhou2 1Zhejiang University 2Institute of Thermal Science and Power Engineering, Zhejiang University | [305] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [172] Modal parameters assessment of civil engineering structures using long-range LIDAR velocimeter for SHM P Guéguen1, M Valla2, B Augère2 and D Goular2 1ISTerre, Université Grenoble Alpes 2ONERA | [173] In-service railway

track condition monitoring by analysis of axle box accelerations for

small to mid-size infrastructure operators J C Groos, P Havrila and L Schubert German Aerospace Center (DLR) – Institute of Flight Systems | [162] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION |

|

17.15-18.30 18.30-21.00 | Evening function – Available to all full-time delegates and delegates who booked the optional extra sightseeing tour at registration Two-course meal with wine Room: London 9 Tour of London (departing from the side entrance of the hotel) |

||||||

| Wednesday 14 June | |||||||

| 08.00 onwards | Registration – Room: ILEC Conference Centre Foyer | ||||||

| Training workshops – Available to all full-time delegates, those who booked daily attendance to Wednesday 14 June 2017 and exhibitors Room: Hyde Park (first floor) | |||||||

| 08.30-09.00 | Plenary Keynote Lecture [201] BINDT strategy and the NDT, CM and SHM community: 2017 update C Sinclair, CEO of BINDT, UK Chair: Professor L Gelman Room: London 7 and 8 | ||||||

| 09.00-09.15 | 15-Minute Comfort Break | ||||||

| Session 3A – Vibration diagnostics and prognostics Chair: Dr R Klein Room: London 7 and 8 |

Session 3B – Condition monitoring methods and technologies Chair: Professor L Wang Room: London 1 |

Session 3C – Signal and image processing, pattern recognition and finite element modelling for condition monitoring Chair: Professor E Juuso Room: London 2 |

Session 3D – Condition monitoring methods and technologies Chair: Professor A Hope Room: London 3 |

Session 3E – Acoustic monitoring methods and technologies Chair: I Razuvaev Room: London 4 |

Session 3F – Condition monitoring and NDT methods and technologies Chair: Dr S Kolokolnikov Room: London 5 |

Session 3G – Condition monitoring methods and technologies Chair: Dr M Papaelias Room: London 6 | |

| 09.15-09.35 | [202] An analytical model for rolling element/spall interaction in bearing inner race E Madar1, G Kogan1, J Bortman1 and R Klein2 1Ben-Gurion University of the Negev, Israel 2RK Diagnostics, Israel | [203] Electrostatic monitoring of tribo-contacts: then and now H Powrie, L Wang and R Wood University of Southampton | [107] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [205] Development of a safety monitoring system for large gantry cranes K Ding, N Zhao, H Wang, Y Zhang and Y He China Special Equipment Inspection and Research Institute | [206] Application of acoustic emission in integrated structural health monitoring systems: Problems, solutions and results I Razuvaev Alcor Corp | [207] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [208] Evaluation of damage mechanics of industrial wind turbine gearboxes V J Junior1, J Zhou1, S Roshanmanesh1, F Hayati2, S Hajiabady1, X Y Li1, H Dong1 and M Papaelias1 1School of Metallurgy and Materials, University of Birmingham 2School of Engineering, University of Birmingham |

| 09.35-09.55 | [209] Vibration analysis of a double cardan shaft M Battat1, R Klein1,2 and J Bortman1 1Ben-Gurion University of the Negev, Israel 2RK Diagnostics, Israel | [210] Condition monitoring of PTFE composite material bearings through wearing simulation K Yang and Y Gao Wuhan University of Technology, China | [211] Steel grade-specific stress predictions to support roller leveller maintenance R-P Nikula and K Karioja University of Oulu | [212] Review of condition indicators for transformers in marine applications S Bhandari1, M Chai1, S Aravinth1, S K Panda1, N Sivakumar2 and A K Gupta2 1National University of Singapore 2Rolls-Royce Singapore Pte Ltd | [213] The advanced acoustic emission technique for condition monitoring of industrial facilities T B Petersen, V V Shemyakin, A B Samokhvalov and V Y Chernigovsky DIAPAC Ltd | [214] Novel active ultrasonic reflectometry measurement technology for monitoring the condition and performance of hydrodynamic bearings P Harper Tribosonics Ltd | [215] Indicative bearing fault analysis of wind turbine generator bearings using tower vibration E Mollasalehi University of Calgary |

| 09.55-10.15 | [216] Phase editing for enhanced diagnosis of bearing faults under variable speed conditions L Barbini1, M Eltabach2 and J L duBois1 1Mechanical Engineering, University of Bath 2CETIM, Senlis, France | [217] Early failure detection for bearings in electrical environments M Zuercher1, V Heinzler1, E Schlücker1, K Esmaeili2, T J Harvey2, W Holweger2 and L Wang2 1Institute of Process Machinery and Systems Engineering, Germany 2University of Southampton | [218] Crusher wear monitoring in the IoT framework A Koistinen, J Laurila and E Juuso University of Oulu | [356] Data analytics for condition monitoring on-board container ships M Chai1, S Bhandari1, S K Panda1, D Wu2, X Qing Chen2 and W Ping Koh2 1National University of Singapore 2Singapore Technologies Marine Ltd | [220] Acoustic emission source location at industrial structures monitoring A B Samokhvalov DIAPAC Ltd | [221] Direct load measurement of a wind turbine high-speed shaft bearing in the field G Nicholas1, T Howard1, R Dwyer-Joyce1, J Wheals2 and D Benchebra2 1The University of Sheffield 2Ricardo Innovations Ltd, Midlands Technical Centre | [222] Task-specific condition monitoring of industrial CT systems using dedicated data quality measures T Schönfeld and M Bartscher Physikalisch-Technische Bundesanstalt, Germany |

| 10.15-11.30 | Exhibitors' Spotlight Session with Tea, Coffee and Exhibition – Room: London 9 | ||||||

| 11.30-13.30 | Lubrication Analysis Workshop Steve Greenfield – Room: Hyde Park (first floor) | ||||||

| 11.30-11.50 | [223] Clearance influence on vibrations of gear systems I Dadon1, N Koren1, J Bortman1, R Klein2 and M G Lipsett3 1Ben-Gurion University of the Negev, Israel 2RK Diagnostics, Israel 3University of Alberta, Canada | [224] Advanced signal processing techniques for wind turbine gearbox bearing failure detection K Esmaeili1, M Zuercher2, L Wang1 , T J Harvey1 and W Holweger3 1University of Southampton 2Process Machinery and System Engineering, Germany 3Schaeffler Technologies, Germany | [225] Advanced data analysis in condition-based operation and maintenance E K Juuso University of Oulu | [226] Correlation-based condition monitoring of a roller chain T Kärcher and G Schullerus Reutlingen University | [227] Investigation of AE signal propagation in vessels and tanks in operation A Kamyshev, I Razuvaev and E Suchkov Alcor Corp | [228] Invited overview presentation Training of shape memory effect for actuation and structural applications Professor R Fu | [229] Initial steps towards an automated system for monitoring the TIG welding process D Bacioiu1, G Melton2, M Papaelias1 and R Shaw2 1University of Birmingham 2TWI Ltd |

| 11.50-12.10 | [230] High-definition gearbox monitoring C Larsson SPM Instrument | [231] Design of miniature viscosity sensors based on a single-chip microcomputer K Yang1,2, X Zeng1 and X Sun2 1Reliability Engineering Institute, Wuhan University of Technology 2National Engineering Research Center for Water Transport Safety, Wuhan University of Technology | [232] Transient dynamic finite element modelling of flexible rotor systems with non-linear fluid film bearings and faults P S Heyns, A Krüger and A J Oberholster University of Pretoria | [175] Parametric optimization of TIG welding process parameters in low-alloy steel sheets A I Butt, I Saleem and K Nasim National Engineering and Scientific Commission, Islamabad | [234] Application of acoustic emission method to diagnose damage in pneumatic cylinders H Mahmoud1, F Vlasic2, P Mazal1 and M Jana3 1Brno University of Technology, Brno, Czech Republic 2Center of Technical Diagnostic ZD Rpety – DAKEL, Czech Republic 3Poličské Strojírny a.s., Policka, Czech Republic | [235] Using ultrasound to improve lubrication practices C Hallum UE Systems UK & Ireland | [236] Welding quality monitoring using acoustic emission techniques M Xing1, M Papaelias1, Z Huang1, G Melton2 and R Shaw2 1University of Birmingham 2TWI Ltd |

| 12.10-12.30 | [237] The novel higher-order technique and the wavelet spectral cross-covariance for gearbox vibration condition monitoring L Gelman1, K Solinski2, B Shaw3 and M Vaidhianathasamy3 1Cranfield University 2Meggitt Sensing Systems Switzerland 3Newcastle University | [238] Integrated smart bearings for next generation aero-engines. Part 1: Development of a sensor suite for automatic bearing health monitoring I Bashir1, L Wang1, T J Harvey1, B Zaghari2, A S Weddell2 and N M White2 1National Centre for Advanced Tribology at Southampton (nCATS), University of Southampton 2Electronics and Computer Science, University of Southampton | [239] High-frequency transformer modelling using state space representation for FRA studies A Abu-Siada Curtin University of Technology, Australia | [374] Successful detection of CUI via electrical impedance spectroscopy on an industrial scale G Diamond Inspection Technologies Ltd | [241] Condition monitoring method of satellite flywheel system based on acoustic parameter fusion T He1, H Wang2, W Liu1, Q Pan1 and Q Tao2 1School of Transportation Science and Engineering, Beihang University 2Beijing Institute of Control Engineering | [242] Training of NDT personnel in the field of condition monitoring and technical diagnostics based on the metal magnetic memory method S Kolokolnikov and A Dubov Energodiagnostika Co Ltd, Moscow, Russia | [243] Effective automated analysis of acoustic emission signals N Angelopoulos and M Papaelias University of Birmingham |

| 12.30-12.50 | [244] Online real-time monitoring system through using adaptive angular-velocity VKF order tracking T-C Yeh and M C Pan National Central University, Taiwan | [245] Integrated smart bearings for next-generation aero engines. Part 2: Energy harvesting and wireless communication development B Zaghari1, A Weddell1, N White1, I Bashir2, T J Harvey2 and L Wang2 1Electronics and Computer Science, University of Southampton 2National Centre for Advanced Tribology at Southampton (nCATS), University of Southampton | [246] Advanced prognostics based on intelligent data analysis E K Juuso University of Oulu | PLEASE NOTE THE BELOW PAPER HAS BEEN ADDED TO THE PROGRAMME [176] Decarburisation in low carbon alloy steels and optimisation of heat treatment parameters A Butt, I Saleem and K Naseem National Engineering and Scientific Commission, Islamabad | [248] Preliminary investigation of slurry pipe local motion due to particles near the pipe wall C Ying and M Lipsett University of Alberta, Canada | [249] Application of ultrasound technology in condition monitoring P Holstein and C Probst SONOTEC | |

| 12.50-14.00 | Lunch and Exhibition – Room: London 9 and ILEC Conference Centre Foyer |

||||||

| 14.00-14.30 | Plenary Keynote Lecture [251] The role of computational science and engineering in condition monitoring Professor D Drikakis Chair: Professor L Gelman Room: London 7 and 8 |

||||||

| 14.30-14.45 | 15-Minute Comfort Break |

||||||

| 14.30-16.30 | Vibration Analysis Workshop Dean Whittle – Room: Hyde Park (first floor) | ||||||

| | Session 4A – Condition monitoring methods and technologies Chair: I Petrunin Room: London 7 and 8 | Session 4B – Condition monitoring methods and technologies Chair: Professor S Noroozi Room: London 1 | Session 4C – Condition monitoring methods and technologies Chairs: Professor S Lahdelma and K Karioja Room: London 2 | Session 4D – Condition monitoring methods and technologies monitoring Chair: Professor M Lipsett Room: London 3 | Session 4E – Condition monitoring methods and technologies – Acoustic emission Chair: I Razuvaev Room: London 4 | Session 4F – Structural health monitoring Chair: Professor E Hristoforou Room: London 5 | Session 4G – Condition monitoring methods and technologies Chair: Dr M Papaelias Room: London 6 |

| 14.45-15.05 | [252] Identification of multi-faults in rotor-bearing system using spectral kurtosis and EEMD X Gong1, B Zhao1, A Georgiadis2, W Du1 and Z Xiao1 1Zhengzhou University of Light Industry, China, 2Leuphana University of Lüneburg, Germany | [253] Visualising kinematics of an elastic Ossur ESR prosthetic foot using novel low-cost optical tracking systems S Noroozi1, N Aslani1, P Sewell1, A Ong2 and M Khoo2 1Bournemouth University 2Department of Mechanical Engineering, University of Malaya | [254] Methods for automatic condition monitoring K Karioja University of Oulu | [255] Integrated generator rotor and stator winding condition monitoring M Sasic, J Letal and G C Stone Iris Power – Qualitrol, Canada | [256] Application of acoustic emission for evaluating the technical condition of equipment in the process of RBI A Miseiko Aegis Scientific and Technical Center LLC | PLEASE NOTE THE BELOW PAPER HAS NOW BEEN CANCELLED [257] Invited overview presentation Stress tensor distribution monitoring in ferromagnetic steels P Vourna1, A Ktena2 and Ε Hristoforou1 1Laboratory of Electronic Sensors, National Technical University of Athens 2Department of Electrical Engineering, Technological Educational Institute (TEI) of Sterea Ellada, Greece | [258] Increasing the reliability, availability, maintainability and safety of railway network operations through effective remote condition monitoring E H Gunel1, P Yilmazer1, U Bicer1, B B Altintas1, A Amini2, P Vallely2,3, Z Huang2, F P Garcia Marquez4, S Kaewunruen2 and M Papaelias2 1Turkish State Railway Research and Technology Centre, Turkey 2University of Birmingham 3Network Rail Infrastructure Limited 4ETSII, Universidad de Castilla-La Mancha, Ciudad Real |

| 15.05-15.25 | [259] Detection and diagnosis of rail surface defects using signal and image processing techniques A K Ng1, L Martua1, J Yebra2 and G Sun2 1Singapore Institute of Technology 2Land Transport Authority, Singapore | [260] Monitoring the suitability of the fit of a lower-limb prosthetic socket using an artificial neural network in commonly encountered walking conditions P Davenport1, S Noroozi1, P Sewell1 and S Zahedi2 1Bournemouth University 2Chas A Blatchford and Sons Ltd | [261] Axle mounted piezoelectric energy harvester for continuous energy harvesting from rotation and vibration M Leinonen, J Palosaari, J Juuti and H Jantunen Microelectronics Research Unit, University of Oulu | [262] Multiple physical signal-based performance degradation prediction of slewing bearing H Wang1, B Zhang1, R Hong1, X Gao2 and B Pang3 1School of Mechanical and Power Engineering, Nanjing Tech University 2Shanghai OujiKete Slewing Bearing Co Ltd 3Luoyang LYC bearing Co Ltd | [263] Low-speed bearing condition monitoring with acoustic emission techniques F Alshammari Cranfield University | [271] In-situ inspection of composite isolators in 500 kV live overhead transmission lines by computed radiography H Fujiwara1, A H Shinohara1, E J Silva Jr1, G J V Xavier1, H B D T Lott Neto2, P R R Britto2 and M A B Fontan2 1UFPE – Federal University of Pernambuco, Brazil 2STN – Sistema de Transmissão do Nordeste SA | [265] Wayside detection of axle bearing faults in rolling stock through correlation signal processing Z Huang1, M Papaelias1 and Z Q Lang2 1University of Birmingham 2University of Sheffield |

| 15.25-15.45 | [266] Effects of gear manufacturing errors on rack and pinion steering meshing D Marano1, A Piantoni1, L Tabaglio1, M Lucchi1, M Barbieri2 and F Pellicano2 1ZF TRW 2University of Modena and Reggio Emilia Presented by A Zippo | PLEASE NOTE THE BELOW PAPER HAS NOW BEEN CANCELLED [267] Condition monitoring of a compressor motor unit: an investigation of abnormal high-pitch noise A Ghaffar1, A Rahman1, S Mahathir2, S Mohd al-Attas2, S Noroozi3 and M Dupac3 1University of Malaysia Pahang 2Quadrant 2 Technologies 3Bournemouth University | [268] Signal processing applications based on real and complex order derivatives J Laurila1 and S Lahdelma2 1University of Oulu 2Tirriäisentie, Oulu, Finland | [269] Investigating the diagnostic capabilities of monitored system parameters to support improvements in conveyor operation and maintenance O F Gebler1, B Hicks1, A Harrison1 and M Barker2 1University of Bristol 2Stirling Dynamics | [270] Acoustic monitoring of subsea blowout preventers using mixtures of hidden Markov models M Svensén1, D S Hardwick1, H E G Powrie1, G K Nielsen2 and Y Villanger2 1GE Aviation Digital 2Naxys AS | [264] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [272] Remote condition monitoring of railway axle bearings based on data fusion from several sensors E Giannouli1,2, Z Huang1, A Amini1, P Vallely1,3, S Soua2,4, F P G Marquez5 and M Papaelias1 1University of Birmingham 2National Structural Integrity Research Centre 3Network Rail Infrastructure Limited 4TWI Limited, Cambridge 5ETSII, Universidad de Castilla-La Mancha |

| 15.45-16.15 | Tea, Coffee and Exhibition – Room: London 9 and ILEC Conference Centre Foyer | ||||||

| 16.15-16.35 | [273] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [274] In-line water quality monitoring system (IWQMS) K Abuowda1, A A Issa2, A Hamid Soliman3 and H H Aly3 1Bournemouth University 2Al-Azhar University 3Staffordshire University | [275] An improved blade forced response model for non-intrusive blade vibration monitoring and signal simulation P S Heyns and C B Church University of Pretoria | [276] A strategy for the selection of condition monitoring methods T-H Pham1, J Windelberg1, S Ferreiro2 and I Bravo-Imaz2 1German Aerospace Center (DLR) – Institute of Flight Systems 2Intelligent Information Systems, Spain | [277] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [278] Evaluation of reinforced concrete of foundations and concrete towers of transmission lines 230 kV by a high-energy computed radiography system with betatron A H Shinohara1, J F A G Wavrik1, H Fujiwara1, V S Barros1, P Regis1, H J Khoury1, P I Sá2 and E Garcez2 1UFPE – Federal University of Pernambuco, Brazil 2CHESF – Companhia Hidrelétrica do São Francisco, Brazil | [279] Integrating remote condition monitoring of railway infrastructure with high-speed inspection P Vallely1, 2 and M Papaelias1 1University of Birmingham 2Network Rail Infrastructure Limited |

| 16.35-16.55 | [280] Improving damage diagnosis of gearboxes run in non-stationary conditions by novel adaptation of spectral kurtosis and technology parameters L Gelman and S Kolbe Cranfield University | PLEASE NOTE THIS PAPER HAS NOW BEEN CANCELLED [281] Sensor technology development for use in condition monitoring M Koohgilani1 and K Maynard2 1Bournemouth University 2UKTA | [282] A case study of image data processing in automated ultrasonic testing-based aerospace composites inspection G Feng1, J Sun1, A Y B Chong1, J Kanfoud1, T-H Gan1, M Kimball2, M Al Rashed2, L M Vega2, A Garcia2 and G S Virk2 1Brunel Innovation Centre, Cambridge 2Innovative Technology and Science Limited, Cambridge | [283] How system observability affects fault classification accuracy and implications for sensor selection and placement for condition monitoring M Lipsett University of Alberta, Canada | [284] Acoustic vibration monitoring T Murphy Reliability Team Limited | [285] Case study involving failure of titanium impellers in a hydrogen environment M Dobrotvorskii CJSC NPO Lencor | [286] Remote condition monitoring of the structural integrity of rails and crossings S Shi1,2, Z Huang1, S Kaewunruen3, P Vallely1, S Soua2,4 and M Papaelias1 1School of Metallurgy and Materials, University of Birmingham 2National Structural Integrity Research Centre, Cambridge 3School of Engineering, University of Birmingham 4TWI Limited, Cambridge |

| 16.55-17.15 | [287] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [288] Condition monitoring through the ages M Koohgilani Bournemouth University | [289] An adaptive thresholding segmentation method of ferrographic image for oil condition monitoring B Xu1, G Wen1,2, Z Zhang1 and F Chen1 1The Research Institute of Diagnosis and Cybernetics, Xi’an Jiaotong University 2School of Mechanical Engineering, Xinjiang University | [290] Condition monitoring of railway overhead lines: correlation between geometrical parameters and performance parameters M Carnevale1, A Collina1 and M Palmiotto2 1Dipartimento di Meccanica, Politecnico di Milano 2Rete Ferroviaria Italiana SpA | [291] Using ultrasound to solve problems on assets that do not rotate T Murphy Reliability Team Limited | [292] Advantages of scanning methods in NDT G Por, M Agocs, E Kocso and J Molnar University of Dunaujvaros | [293] Operational safety assessment research of the rail system Y Qin Beijing Jiaotong University |

| 17.15-17.35 | [294] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [295] An investigation into the effect of boundary conditions on the mechanical characteristics of an energy storing and returning prosthetic foot subjected to non-destructive testing J Hawkins, S Noroozi, M Dupac and P Sewell Bournemouth University | [296] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [297] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [298] Monitoring of the injection moulding process of polymers with acoustic emission sensors T Kek and J Grum Faculty of Mechanical Engineering, University of Ljubljana | [299] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [300] Application of AE technology in continuous monitoring of pipelines of power units operating at high temperatures B E Paton, L M Lobanov, A Ya Nedoseka, S A Nedoseka, O S Milenin and E O Paton Electric Welding Institute of the NAS of Ukraine |

| 17.35-18.35 | ISCM Annual General Meeting – Room: Hyde Park (first floor) |

||||||

| Free evening for delegates to arrange their own activities (no evening meal will be included in today's programme) |

|||||||

| Thursday 15 June | |||||||

| 08.00 onwards | Registration – Room: ILEC Conference Centre Foyer | ||||||

| 09.00-09.30 | Plenary Keynote Lecture [301] Study on condition monitoring of major mechanical systems based on health management Professor G Shen and Professor L Yuan, China Chair: Professor L Gelman Room: London 7 and 8 | ||||||

| 09.30-09.45 | 15-Minute Comfort Break | ||||||

| Session 5A – Sensors and actuators for condition monitoring Chair: Professor J Bortman Room: London 7 and 8 |

Session 5B – Structural health monitoring Chair: Professor L Cheng Room: London 1 |

Session 5C – Condition monitoring methods and technologies – Stress/strain analysis Chair: D Whittle Room: London 2 |

Session 5D – Maintenance Chair: Dr J Yebra Room: London 3 |

Session 5E – Vibration condition monitoring methods and technologies Chair: Dr J Liska Room: London 4 |

Session 5F – NDT methods and technologies Chair: Dr H Chandra Room: London 5 |

Session 5G – Signal processing: Identification, fault diagnosis and reliability for complex system monitoring – Part 3 Chair: Dr N Martin Room: London 6 | |

| 09.45-10.05 | [302] Energy harvesting for wireless and autonomous load monitoring sensor G Bastard1 and Y Hebrard2 1Safran Aircraft Engines 2SKF Aerospace | [303] & [330] Invited overview presentation Guided wave approach for structural health monitoring L Cheng Polytechnic University, Hong Kong | [311] On-stream optical measurement to monitor creep strain J W Noteboom and H J M Hulshof DEKRA Solutions BV, The Netherlands | [171] Beyond traditional condition monitoring – combining efficiency and performance indicators with typical condition monitoring parameters K Daskalakis James Fisher Mimic | [306] Rotating blades state evaluation using relative rotor vibration measurements considering the impact of operating conditions V Vasicek, J Liska and J Jakl NTIS – European Centre of Excellence, University of West Bohemia, Pilsen | [307] Automated detection of welding defects in pipelines from radiographic double wall double images N Boaretto and T Centeno Federal Institute of Santa Catarina (IFSC), Brazil | [315] Early fault detection thanks to distributed optical fibre sensors E Buchoud, J-M Hénault, S Desforges and F Martinot EDF R&D, France |

| 10.05-10.25 | [309] A wireless rolling bearing cage temperature sensor for aerospace transmission diagnostic application Y Hebrard SKF Aerospace | [304] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [312] Determination of the optimal maintenance threshold and periodicity of condition monitoring V Ulansky1 and A Raza2 1National Aviation University, Kiev 2DOPA, Overseas Projects and Maintenance | [313] Measurement and evaluation of shaft torsional vibrations to reveal the excitation sources of the rotating blades J Jakl, J Liska, S Kunkel and J Strnad NTIS – European Centre of Excellence, University of West Bohemia, Pilsen | [314] Ultrasonic guided wave technique for the size and depth estimation of delamination-type defects in structural health monitoring of composite structures V Samaitis and L Mažeika Ultrasound Research Institute, Kaunas University of Technology | [322] New cepstral techniques for operational modal analysis R B Randall and W A Smith University of New South Wales, Australia |

|

| 10.25-10.45 | [316] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [310] Non-linear methods for rapid go/no-go monitoring N T Sewell, J C S Wright and J R Wright Theta Technologies Limited | [318] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [319] Development of a Bayesian network (BN) model to estimate health factors for predictive maintenance strategy of large two-stroke marine engines M Usman1,3, D Shorten2 and Z Yang3 1Lloyd's Register EMEA, Global Technology Centre, Southampton 2Optimain, UK Ltd 3Liverpool Logistics Offshore and Marine Research Institute | [320] Engine condition and performance monitoring using cylinder head stress wave analysis M Cox Practice Care Maintenance Services Ltd | [321] New trends of NDT-based condition monitoring of industrial and power plants F Niese, P Jäckel, U Rabe, H-G Herrmann and K Szielasko Fraunhofer Institute for Nondestructive Testing IZFP | |

| 10.45-11.45 | Tea, Coffee and Exhibition – Room: London 9 and ILEC Conference Centre Foyer | ||||||

| Session 6B – Structural health monitoring Chair: D Whittle Room: London 1 |

Session 6C – Condition monitoring methods and technologies – Stress/strain analysis Chair: Dr S Ganeriwala Room: London 2 |

Session 6D – Predictive maintenance and condition monitoring Chair: Dr J Yebra Room: London 3 |

Session 6E – Vibration condition monitoring methods and technologies Chair: Professor A Hope Room: London 4 |

Session 6F – Condition monitoring methods and technologies Chair: Dr H Chandra Room: London 5 |

|||

| 11.45-12.05 | [324] Structural health monitoring of composite pressure vessels using guided ultrasonic waves Y Lugovtsova and J Prager Bundesanstalt für Materialforschung und – prüfung (BAM) | [325] Location of impact on composite plates using the piezoelectric rosettes technique A Razzini, V Lopes Jr and V Rosa UNESP – São Paulo State University | [326] Identification of damage ignition time with high accuracy using a CUSUM chart: four case studies B Al-Najjar and H Algabroun Linnaeus University, Sweden | [327] Blade synchronous frequencies identification based on non-uniform Fourier transform of multisampling data L Yue and H Liu College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing | [334] Control and instrumentation in renewable fuel production I Petrunin, H Chandra and L Gelman Cranfield University | ||

| 12.05-12.25 | [336] Simulation and big data analysis for SHM systems: fractal approach V Vengrinovich1,2, D Vintov1, V Ryabtsev3 and A Nichanovich1 1Institute of Applied Physics, National Academy of Sciences of Belarus 2Tomsk National Research State University 3Belarus State Technical University | [331] Investigation into the cause of cab mounting bolt failures on a track renewal train M Cox Practice Care Maintenance Services Ltd | [332] Improving reliability with CBM Y Wang and G Rolfe SKF (UK) Ltd | [333] High-definition gearbox monitoring C Larsson SPM Instrument | [340] Concept and experience of wire rope condition monitoring D Slesarev1, D Sukhorukov1, I Shpakov1 and C Bonetti2 1Intron Plus, Moscow, Russia 2VisionTek, Brescia, Italy | ||

| 12.25-12.45 | [317] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [427] Using residual analysis for the detection of faults in unsteadily operating rolling element bearings D Helm and M Timusk Laurentian University, Canada | [338] Universal health and usage monitoring system (HUMS) enterprise solution W Y Yeo Singapore Technologies Kinetics Ltd | [339] Algorithms for refinement of the shaft rotational speed for solving the problems of vibration diagnostics of rotary equipment Y Aslamov, I Davydov, A Zolotarev and A Aslamov VibroBox | [328] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | ||

| 12.45-14.00 | Lunch and Exhibition – Room: London 9 and ILEC Conference Centre Foyer |

||||||

| 12.45-14.00 | International Scientific Advisory Committee Lunch: By invitation only – Room: London 7 and 8 | ||||||

| 14.00-14.30 | Plenary Keynote Lecture [341] Structural health monitoring: new paradigms for aerospace and process industries using guided ultrasonic waves Professor K Balasubramaniam, India Chair: Professor L Gelman Room: London 7 and 8 |

||||||

| 14.30-17.00 | Presidents and CEOs of the ISCM Liaison Members Meeting: By invitation only – Room: Hyde Park (first floor) |

||||||

| 14.30-14.45 | 15-Minute Comfort Break | ||||||

| | Session 7A – Sensors and actuators for condition monitoring Chair: Dr G Zusman Room: London 7 and 8 | Session 7B – Condition monitoring methods and technologies Chair: Professor P Trampus Room: London 1 | Session 7C – Instrumentation for condition monitoring Chair: Dr J Yebra Room: London 2 | Session 7D – Predictive maintenance and condition monitoring Chair: Dr J Yebra Room: London 3 | Session 7E – Vibration condition monitoring methods and technologies Chair: Professor A Hope Room: London 4 | Session 7F – NDT and CM methods and technologies Chair: Dr S Kolokolnikov Room: London 5 | |

| 14.45-15.05 | [342] The effective monitoring of key rotor parameters with a smart energy harvesting device for AC machines S Tvorić, A Elez and A Kapović KONČAR | [343] Contribution of CM and NDE to asset management P Trampus University of Dunaújváros | [344] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [345] A decade of points condition monitoring: the Balfour Beatty rail experience T A Bradbeer Balfour Beatty Rail | [346] Sparse wavelet decomposition of signals for solving vibration diagnostics problems Y Aslamov, I Davydov, A Zolotarev and A Aslamov VibroBox | [347] Airborne ultra-broadband NDT with an optical microphone and a thermoacoustic emitter T Herbst Xarion Laser Acoustics GmbH | |

| 15.05-15.25 | [348] A comparative study on the use of different methods for gravitational acceleration cancellation providing pure tangential acceleration for condition monitoring Z Mones, G Feng, F Gu and A D Ball University of Huddersfield | [349] Research on condition monitoring based on health management of large amusement rides Y Liu1,2, G Shen3, Z Zhao1 and Y Shen3 1Wuhan University of Technology 2Qinzhou University, Qinzhou 3China Special Equipment Inspection and Research Institute, Beijing | [350] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [351] The shift to unattended measurement of track geometry D Thompson Balfour Beatty Rail | [352] Resolving structural vibration issues on a multi-stage pump M Shalabi and N Peton GE Oil & Gas – Bently Nevada | [359] Monitoring of risks based on early

diagnostics of equipment and structures metal state in stress

concentration zones – the sources of damage development A Dubov and S Kolokolnikov Energodiagnostika Co Ltd | |

| 15.25-15.45 | [354] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [355] Experimental results from condition monitoring of railway infrastructure and rolling stock F Cangioli, M Carnevale, S Chatterton, A De Rosa and L Mazzola Dipartimento di Meccanica, Politecnico di Milano, Italy | [219] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [357] Utilising holistic condition monitoring on MV/HV motors to reduce unplanned downtime M Foxall1, L Dodd1, A Mellor2 1High Voltage Partial Discharge Ltd 2Pragmatic Maintenance and Reliability Ltd | [358] Application of wavelet packet transform and envelope analysis to non-stationary vibration signals for the fault diagnosis of a reciprocating compressor U E Ogbulafor, G Feng, Z Mones, A D Ball and F Gu University of Huddersfield | [365] High-energy 3D computed tomography (CT) metrology and inspection: one operation B Ingham Rolls-Royce plc | |

| 15.45-16.15 | Tea, Coffee and Exhibition – Room: London 9 and ILEC Conference Centre Foyer | ||||||

| 16.15-16.35 | [360] Two-wire IEPE or CLD electronics interface sensors with integrated mechanical transducing and temperature monitoring capability G Zusman Vibration Measurement Solutions | [361] A novel decision support model for the composite repair decision process S Thyagarajan1 and V Gollnick2 1German Aerospace Center (DLR) – Institute of Flight Systems 2TUHH Institute of Air Transportation Systems | [362] Improving the measuring accuracy of voltage unbalance for electrical condition monitoring D Makov, A I Antonjuk and O V Polishchuk National Technical University of Ukraine | [369] The

tribodiagnostics of the technical condition of aviation reducers on

stages of surface fatigue wear of their details by ferrography L Shabalinskaia, V V Golovanov, E S Bubnova and A O Melnikov Central Institute of Aviation Motors named after P I Baranov | [364] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [371] Analysis of geomaterials using frequency-modulated continuous wave radar in the K-band J Blanche1,2, D Flynn1, H Lewis2, G Couples2 and R Cheung3 1Institute of Sensors, Signals and Systems, Heriot-Watt University, Edinburgh 2Institute of Petroleum Engineering, Heriot-Watt University 3Scottish Microelectronics Centre, University of Edinburgh | |

| 16.35-16.55 | [366] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [367] Developing a condition-based maintenance concept for fatigue-driven failure of structural parts H Meyer1, S Thyagarajan1 and V Gollnick2 1German Aerospace Center (DLR) – Institute of Flight Systems 2TUHH Institute of Air Transportation Systems | [368] Condition monitoring of a mechanical indexing system with artificial neural networks M Tiboni and C Remino Università degli Studi di Brescia, Italy | PLEASE NOTE THE BELOW PAPER HAS NOW BEEN CANCELLED [375] A practical methodology to allow a ship operator to transition from a planned preventative maintenance culture to one based primarily on risk D C Shorten Optimain Limited | [370] Vibration analysis for wind turbine bearing condition monitoring using wavelet filtering method X Tang1 and L Zhang2 1Huazhong University of Science and Technology, China 2University of Manchester | [377] Magnetic signal variation in the deformation zone of tubular tower B Hu and G Shen China Special Equipment Inspection and Research Center (CSEI) | |

| 16.55-17.15 | [372] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [373] An approach for condition monitoring of rolling stock sub-systems: A case study on HVAC D Seneviratne1, U Martínez-de-Estarrona2, D Galar1,2 and J C Sánchez2 1Luleå University of Technology, Sweden 2Tecnalia Research and Innovation, Spain | [240] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [363] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [376] MBVI systems: why does the world really need yet another condition monitoring technique – and what should we do about it? G Walker Artesis LLP | [353] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | |

| 19.30 for 20.00 | Pre-dinner drinks – Room: ILEC Conference Centre Foyer Conference dinner – Room: London 8 and 9 |

||||||

| Friday 16 June | ||||||

| 08.00 onwards | Registration – Room: ILEC Conference Centre Foyer | |||||

| 09.00-09.30 | Plenary Keynote Lecture [401] A review of high-temperature hydrogen attack (HTHA) modelling, prediction and non-intrusive inspection in refinery applications T Armitt, Lavender NDT International Chair: Professor A Hope Room: London 7 | |||||

| 09.30-09.45 | 15-Minute Comfort Break | |||||

| Session 8A – Condition monitoring and NDT methods and technologies Chair: Professor L Gelman Room: London 7 |

Session 8B – Vibration condition monitoring methods and technologies Chair: Professor A Hope Room: London 1 |

Session 8C – Condition monitoring methods and technologies – Lubrication analysis Chair: S Greenfield Room: London 2 |

Session 8D – Acoustic emission for condition monitoring and NDT Chair: I Razuvaev Room: London 3 |

Session 8E – Infrared thermography for condition monitoring and NDT Chair: C Pearson Room: London 4 |

Session 8F – NDT methods and technologies Chair: T Armitt Room: London 5 | |

| 09.45-10.05 | [402] Novel vibration condition monitoring of gearboxes H Chandra1, L Gelman1, D Manning-Ohren2 and M Patel2 1Cranfield University 2ERIKS | [403] A study of bearing fault diagnosis using deep belief networks T R Lin and K Yu School of Mechanical Engineering, Qingdao University of Technology | [404] Overview of oil debris condition monitoring, early failure detection (EFD) S Greenfield Eaton Aerospace | [405] Invited overview presentation Future direction of acoustic emission method for the integrated structural health monitoring systems I Razuvaev Alcor Corp, Russia | [439] Introduction to thermography for condition monitoring C Pearson Sustainable Construction Group | [407] State-of-the-art prediction and NDE techniques for high-temperature hydrogen attack in piping and equipment T Armitt1, M Nugent2, T Silfies2 and J Dobis2 1Lavender International 2The Equity Engineering Group |

| 10.05-10.25 | [414] Calibration of a reinforced concrete bridge using deep learning D Darsono and M Torbol Ulsan National Institute of Science and Technology, South Korea | [409] ISO standards in vibration analysis S Mills Spectrum CBM | [410] An introduction to offline oil laboratory analysis S Greenfield1 and R Cutler2 1Eaton Aerospace 2Alcontrol | [411] Low-speed bearings T Bradshaw Mistras Group Ltd | [440] Imaging using drones R Faulkner iRed Ltd | [413] Simultaneous multi-mode and disperse ultrasonic guided waves signal analysing using the morphological component analysis (MCA) method X Li, W Guo and X Li University of Electronic Science and Technology of China |

| 10.25-10.45 | [408] Invited overview presentation Current and future directions in non-linear ultrasonic inspection Professor K Balasubramanian | [415] Detecting rolling element bearing defects D Whittle RMS Ltd | [416] An introduction to online oil quality sensor applied to modern gas turbine engine S Greenfield Eaton Aerospace | [417] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [441] Introducing equine thermography E Hall Thermographer, Equine Specialist | [419] High-temperature corrosion monitoring of industrial boilers J Noteboom and M P De Jong DEKRA – MTI |

| 10.45-11.15 | Tea and Coffee – Room: London 9 | |||||

| Session 9A – Condition monitoring methods and technologies Chair: Professor L Gelman Room: London 7 |

Session 9B – Vibration condition monitoring methods and technologies Chair: Professor A Hope Room: London 1 |

Session 9C – Condition monitoring methods and technologies – Lubrication analysis Chair: S Greenfield Room: London 2 |

Session 9D – Acoustic emission for condition monitoring and NDT Chair: K Kirk Room: London 3 |

Session 9E – Infrared thermography for condition monitoring and NDT Chair: C Pearson Room: London 4 |

Session 9F – NDT methods and technologies Chair: T Armitt Room: London 5 | |

| 11.15-11.35 | [420] Detection of flow separation effects in gas turbines using the higher-order spectra L Gelman1, C Parrish1, I Petrunin2 and M Walters2 1Cranfield University 2Rolls-Royce | [421] Using shaft centre line analysis to identify bearing faults based on case studies J Sykes AV Technology | [422] Investigation of process fluid contamination as a potential cause for oil degradation and varnish build-up in a gas compressor lubricating system D Korachkin Swansea Tribology Services Ltd | [423] Analysis of acoustic emission data for structural health monitoring of engineering geometries A A Ghouri and K J Kirk University of the West of Scotland | [442] Thermography as part of the BRE environmental assessment method (BREEAM) C Pearson Sustainable Construction Group | [425] Characterisation and modelling of magnetic domain wall dynamics using reconstituted hysteresis loops from Barkhausen noise B Ducharne1, M Q Le1, G Sebald1, P J Cottinet1, D Guyomar1 and Y Hebrard2 1INSA LYON-LGEF 2SKF Aerospace |

| 11.35-11.55 | [426] Novel vibration diagnosis of deep foundation concrete piles L Gelman and S Kirlangic Cranfield University | [337] Visualising vibration: a ‘game changer’ for troubleshooting, diagnostics and RCA K Gallant RMS Ltd | [428] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [429] Acoustic emission-based condition monitoring technique for power electronic devices used in solar power systems A Badawood1, M Alrweg1, H Musaad1, P Bolourinejad1, A Albarbar1 and C Batunlu2 1Manchester Metropolitan University 2Middle East Technical University, Turkey | [436] Infrared licensing and certification agency (ILCA) and United Kingdom Thermography Authority (UKTA) Bruce Arnold Inspexions | [431] Monitoring of corrosion damage using ultrasonic guided wave tomography Z Fan, J Rao and M Ratassepp School of Mechanical and Aerospace Engineering, Nanyang Technological University |

| 11.55-12.15 | [432] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [433] Diagnosis and treatment of stray current in electric motors, fans, pumps and gearboxes R Thompson Eriks UK | [434] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [435] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [430] THIS SLOT IS AVAILABLE FOR A LATE SUBMISSION | [437] Detection of bond defects in cold roll bonded Al/Al-Sn/Al/steel sheets using Lamb-type guided wave EMATs P J Tallafuss1, A Rosochowski1, S Campbell2 and A R Camacho3 1University of Strathclyde, Glasgow 2MAHLE Engine Systems UK Ltd, Kilmarnock 3Innerspec Technologies Europe S L, 28802 Alcala de Henares, Madrid |

| 12.15-12.45 | Plenary Keynote Lecture [438] Condition monitoring for Industry 4.0 Professor R Smid, Czech Republic Chair: Professor L Gelman Room: London 7 and 8 |

|||||

| 12.45-13.15 | Panel Session |

|||||

| 13.15-13.30 13.30 | Conference Close and Awards Presentation – Room: London 7 Lunch – Room: London 9 |

|||||

The British Institute of Non-Destructive Testing, Midsummer House, Riverside Way, Bedford Road, Northampton NN1 5NX, UK.

Tel: +44 (0)1604 438300; Fax: +44 (0)1604 438301; Email: wccm@bindt.org