Any personal information provided to or to be gathered by bindt.org and ndtnews.org is controlled primarily by The British Institute of Non-Destructive Testing, Midsummer House, Riverside Way, Bedford Road, Northampton NN1 5NX, UK.

The information we learn from customers helps us personalise and continually improve your shopping experience at bindt.org and ndtnews.org. We use the information to handle orders, deliver products and services, process payments, communicate with you about orders, products, services and promotional offers, update our records and generally maintain your accounts with us.

Information about our customers is an important part of our business and we are not in the business of selling it to others.

How Secure Is Information About Me?

- We work to protect the security of your information during transmission by using Secure Sockets Layer (SSL) software, which encrypts information you input.

- We reveal only the last five digits of your credit card numbers when confirming an order. Of course, we transmit the entire credit card number to the appropriate credit card company during order processing.

- We maintain physical, electronic and procedural safeguards in connection with the collection, storage and disclosure of personally identifiable customer information. Our security procedures mean that we may occasionally request proof of identity before we disclose personal information to you.

- It is important for you to protect against unauthorised access to your password and to your computer. Be sure to sign off when you finish using a shared computer.

The British Institute of Non-Destructive Testing

Midsummer House

Riverside Way

Bedford Road

NORTHAMPTON

NN1 5NX

United Kingdom

Tel: +44 (0)1604 438300

Fax: +44 (0)1604 438301

E-mail: info@bindt.org

Web: www.bindt.org

The British Institute of Non-Destructive Testing is a Limited Company (Reg. No. 969051, England) and a Charity (Reg. No. 260666). Registered Office: Midsummer House, Riverside Way, Bedford Road, Northampton NN1 5NX, UK.

VAT Reg. No. 581 2105 68

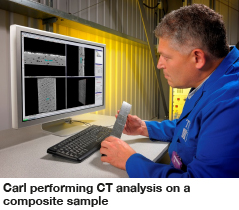

Our interviewee for this instalment of People in NDE is Carl Forrest, a Senior Technician specialising in advanced radiography at TWI Wales in Port Talbot…

Our interviewee for this instalment of People in NDE is Carl Forrest, a Senior Technician specialising in advanced radiography at TWI Wales in Port Talbot…

Comments by members

This forum post has no comments, be the first to leave a comment.