Condition Monitoring

Certification Services Division

What is condition monitoring?

Techniques collectively referred to as condition monitoring (CM) have a common objective of indicating the early signs of deterioration or malfunction, and wear trending in structure, plant and machinery through surveillance, testing and analysis.

Certification of competence in condition monitoring

Why do I need a certificate of competence?

One of the many benefits of the scheme will be to confer wider recognition of personnel who contribute to effective plant asset management and condition-based management and predictive maintenance.

The qualification will also facilitate compliance with ISO 9001:2000, Quality management systems – Requirements for training and qualification of personnel.

Independent certification enhances confidence in competence!

Who is providing certification for condition monitoring personnel?

The British Institute of Non-Destructive Testing (BINDT) has developed a scheme for the certification of competence of personnel engaged in various condition monitoring disciplines as part of the internationally recognised PCN Scheme.

The resulting certification will comply with the requirements of international standard ISO 18436.

When and where are examinations available?

Examinations are widely available through the existing network of PCN Authorised Qualifying Bodies and Examination Centres, and at the premises of selected organisations currently offering condition monitoring training.

What condition monitoring technologies will be covered?

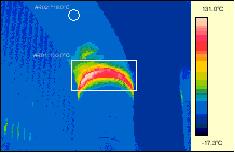

Qualification examinations being offered cover vibration analysis, acoustic emission, infrared thermography and lubrication analysis.

Successful candidates will be issued PCN certificates of competence at one of three levels in each of the technologies offered.

Category 1 practitioners are certified to ISO 18436/4 Field or ISO18436/5 Lab and are thus qualified to supervise industrial machinery lubrication, lubricant sampling and basic lubricant testing and analysis according to established and recognised procedures.

Category 2 is the minimum standard to undertake all competencies of Category 1 (Field and Lab) and, additionally, to schedule and direct machinery lubricant management and lubricant analysis according to established and recognised procedures.

Category 3 is the highest standard one can be certified to ISO 18436/4 Field or ISO18436/5 Lab for programme managers, diagnosticians and prognosticians, to perform all competencies specified for Category 2 (Field and Lab) and, additionally, to manage and implement lubricant condition monitoring programmes.

Techniques collectively referred to as condition monitoring (CM) have a common objective of indicating the early signs of deterioration or malfunction, and wear trending in structure, plant and machinery through surveillance, testing and analysis.

Certification of competence in condition monitoring

Why do I need a certificate of competence?

One of the many benefits of the scheme will be to confer wider recognition of personnel who contribute to effective plant asset management and condition-based management and predictive maintenance.

The qualification will also facilitate compliance with ISO 9001:2000, Quality management systems – Requirements for training and qualification of personnel.

Independent certification enhances confidence in competence!

Who is providing certification for condition monitoring personnel?

The British Institute of Non-Destructive Testing (BINDT) has developed a scheme for the certification of competence of personnel engaged in various condition monitoring disciplines as part of the internationally recognised PCN Scheme.

The resulting certification will comply with the requirements of international standard ISO 18436.

When and where are examinations available?

Examinations are widely available through the existing network of PCN Authorised Qualifying Bodies and Examination Centres, and at the premises of selected organisations currently offering condition monitoring training.

What condition monitoring technologies will be covered?

Qualification examinations being offered cover vibration analysis, acoustic emission, infrared thermography and lubrication analysis.

Successful candidates will be issued PCN certificates of competence at one of three levels in each of the technologies offered.

Category 1 practitioners are certified to ISO 18436/4 Field or ISO18436/5 Lab and are thus qualified to supervise industrial machinery lubrication, lubricant sampling and basic lubricant testing and analysis according to established and recognised procedures.

Category 2 is the minimum standard to undertake all competencies of Category 1 (Field and Lab) and, additionally, to schedule and direct machinery lubricant management and lubricant analysis according to established and recognised procedures.

Category 3 is the highest standard one can be certified to ISO 18436/4 Field or ISO18436/5 Lab for programme managers, diagnosticians and prognosticians, to perform all competencies specified for Category 2 (Field and Lab) and, additionally, to manage and implement lubricant condition monitoring programmes.

|  |