Study benchmarks capabilities of Dolphitech’s ultrasonic platform

12/04/2022

A recent capability study was carried out by Dolphitech with the aim of providing insight into how effective the company’s Dolphicam2 ultrasonic platform is when inspecting composites on aircraft. Using a carbon fibre- reinforced polymer (CFRP) panel representative of the solid laminate composites on commercial aircraft such as the Boeing 787 and Airbus A350, the study was used to benchmark the capabilities of Dolphitech’s NDT platform.

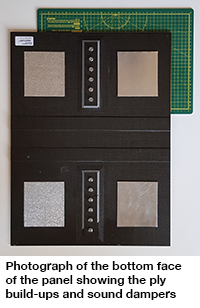

The inspection panel was made to the specification of a Federal Aviation Administration (FAA) NDI Proficiency Specimen 2A and featured various manufacturing flaws typical of aerospace composites; as such, it can be used to assess the performance of NDT equipment. The panel was a 24-ply co-cured substructure (16-ply skin with 8-ply stiffeners and built-up pads). The sample was designed to include a wide range of common flaws in this relatively compact inspection sample.

The Dolphicam2, used with a TRM-CI 5 MHz transducer, was able to successfully inspect the specimen, with all the manufactured flaws clearly resolved and characterised. The flaws were categorised as missing sealant, pillow inserts, Dremel cut, flat-bottomed holes, prepreg backing and grease.

The time and cost savings enabled by the Dolphicam2 are demonstrated by this ability to characterise such a wide range of flaw types with a single set-up. The TRM-CI 5 MHz transducer is versatile and well-suited for many aerospace applications featuring thin to moderate thicknesses of both composites and metals.

www.dolphitech.com