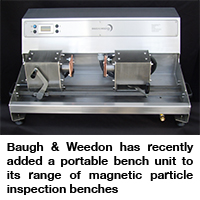

Baugh & Weedon introduces new portable MPI bench unit

12/08/2015

Baugh & Weedon has announced the introduction of a new portable bench unit (PBU) to its exisitng range of magnetic particle inspection (MPI) benches.Baugh & Weedon is renowned within the NDT market, particularly the aerospace industry, for providing very reliable and high-quality MPI benches (with outputs of up to 10,000 A), so it was natural it developed a small table-top unit to complete its MPI bench family.

From the outset, Baugh & Weedon was keen that the PBU ‘ticked all of the boxes’ for the majority of its customers. Therefore, its development team ensured that it fully researched the market and focused on gathering detailed feedback from key potential customers.

The time taken to execute diverse in-depth market research, combined with the due care and diligence given to the R&D process, has resulted in a product that Baugh & Weedon believe is the best and most up-to-date portable MPI bench currently on the market.

In fact, the company sold its first batch of production units before official marketing of the product had even started. This included multiple PBUs sold to one of the top Formula 1 racing teams in the country and another to a North American training institute. The latter was a first for Baugh & Weedon as it had not previously sold MPI benches to the USA.

The PBU only requires a 13 A supply for operation. It offers both AC and HWDC waveforms as standard and uses Baugh & Weedon’s current pre-selection system to set magnetising levels, with a working range of 100 A to 1000 A. The PBU also incorporates shot-time selection and a built-in demagnetising cycle.

Physically, the PBU is a compact design with an integral power pack and a clamping length of up to 350 mm. It is designed and manufactured in the UK by an extremely experienced team and made from the highest quality materials.

A selection of coils for clamping between head and tailstock are offered (including the option of a manual 90° coil rotation feature), while further options are also available. These include the provision of a FWDC waveform with associated low-frequency demagnetisation cycle and flux flow magnetising via coils mounted in the head and tailstocks.

In terms of innovation, two aspects of the PBU design set it apart from the competition. These are the ability to add an inking system to the unit, offering maximum flexibility to the inspector, and the use of a gas spring to provide the clamping pressure on the headstock, which ensures optimum electrical contact with the component under test.

Finally, the PBU is offered at a great price, making it the perfect mix of high performance, guaranteed quality and value for money.

www.bw-nde.com