Testing the waters: new potential for neutrons in NDT

17/01/2020

Water is the foundational substance for life. Yet, for all we depend on it, water is a thorn in our side when it gets somewhere it should not – one that can have dangerous consequences. From concrete structures to circuit boards and to everything in between, NDT professionals in just about every sector and industry need to be able to detect the unwelcome presence of water within materials and components.Due to the unique properties of neutron radiation and the way it interacts with materials, neutron imaging and activation analysis is a powerful, albeit under-explored, tool for investigating the interactions between materials and water. Neutron-producing facilities play a key role in helping NDT professionals root out the presence of moisture, as well as water-based corrosion, in their materials. With new, more accessible sources of neutron radiation on the rise, neutron-based NDT is set to grow into a more widely used tool for finding water in the materials we use to build our society.

Will Ascenzo of nuclear technology company Phoenix LLC explains…

How neutrons detect water

Neutron radiation has two main uses within the field of non-destructive testing and inspection: radiographic imaging and neutron activation analysis. In radiographic imaging with neutron radiation, referred to as neutron radiography or simply as ‘N-ray’, a beam of neutrons is shot through an object and collides with a film or digital sensor behind it to create an image of the object’s internal structure, similar to how industrial X-ray imaging works. In neutron activation analysis, the neutron radiation excites the atoms making up a given material and causes them to give off wavelengths of radiation specific to the material; by analysing the radiation produced, the material’s composition can be determined.

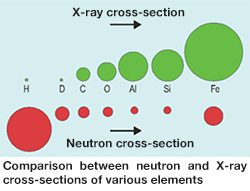

When used for radiography, neutron radiation paints a very different picture compared to X-rays. X-rays, like all other forms of electromagnetic radiation, interact with the electron cloud of the atoms they pass through. The electron cloud is the part of the atom taking up the most space, and denser and heavier elements (which have more electrons) have much larger and more populated electron clouds. As a result, electromagnetic radiation will pass more easily through atoms with smaller and sparsely populated electron clouds and less easily through heavier atoms. The attenuation rate of X-rays, or the likelihood that an X-ray will not pass through a given element, increases linearly with density.

On the other hand, neutron radiation, comprising free neutrons that are not bound up in an atomic nucleus, interacts with materials in a very different way. Neutrons are neutral particles with no charge, so they do not interact with an atom’s electron cloud. The only part of the atom they can interact with is the tiny, dense nucleus, which is packed tightly with protons and other neutrons. As a result, the attenuation rate of neutron radiation does not increase with density. Rather, the rate follows a much less linear trend but, on the whole, neutrons easily penetrate most dense materials while struggling to penetrate many lighter materials.

One of the elements that neutron radiation interacts with very strongly is hydrogen. Hydrogen is the simplest element in the universe, consisting of a single electron surrounding a single proton and neutron. X-rays will easily blast through hydrogen because there is so little to interact with, but not neutron radiation. Hydrogen-rich chemicals (including dihydrogen monoxide) therefore appear clearly and in stark contrast to surrounding materials on a neutron image, just like bones and teeth do in an X-ray taken at a dental check-up.

Water is a particular source of frustration for many conventional forms of non-destructive, non-invasive testing, since hydrogen and oxygen are such light elements that most forms of radiography and tomography cannot ‘see’ them. The same properties that make water nigh-undetectable for X-rays, however, allow neutron radiation to find traces of water and moisture with ease. This makes neutron imaging and activation analysis powerful tools for finding water, both in the world of NDT and in scientific research in general.

Water is a particular source of frustration for many conventional forms of non-destructive, non-invasive testing, since hydrogen and oxygen are such light elements that most forms of radiography and tomography cannot ‘see’ them. The same properties that make water nigh-undetectable for X-rays, however, allow neutron radiation to find traces of water and moisture with ease. This makes neutron imaging and activation analysis powerful tools for finding water, both in the world of NDT and in scientific research in general.While neutron imaging excels at detecting the presence of water within other materials, it does not perform so well when it comes to detecting the presence of other materials within water. All other non-destructive imaging techniques have their own strengths and weaknesses.

Using neutrons to see water moving through machinery

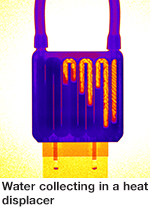

Thanks to the way neutrons interact with water, neutron imaging and neutron activation analysis can be used to see how water and other liquids behave inside objects with complicated internal structures without the need to dismantle or destroy the objects. A neutron image of a sealed device with water inside it can show where the water pools within the device.

With the generation of a high enough neutron flux, or the number of neutrons produced per second, neutron imaging can even be used to create videos of the movement of water through complex devices. For example, at the Paul Scherrer Institute (PSI) researchers used the facility’s powerful neutron source to take a neutron video of a pot of boiling coffee, providing a clear picture of the coffee-brewing process in a way no other form of non-invasive inspection can provide. Taking videos with neutrons requires a very high neutron flux to produce each frame in a reasonable time and currently can only be carried out at research facilities such as PSI, which can produce massive numbers of neutrons per second. However, it is also possible to use this technology to image the inner workings of other devices, such as a running engine block. Should neutron videos become more practical in the future, they could be used to examine the motion of fluids through hydraulics and other mechanical devices.

Using neutrons to find water in electronics and semiconductors

Water and electronics do not mix. Expose a circuit board to water and you not only end up with the metals comprising the board corroding due to water’s chemical properties, but also with the possibility of a short circuit due to water’s high conductivity. Few things can kill an electronic device as effectively as water can.

Neutron radiation is used during quality assurance in electronics and semiconductor manufacturing to detect any amounts of moisture that may have become trapped within the device during the bonding process or before the device was fully sealed and packaged. Moisture that becomes trapped in an electronic device can cause immediate bricking of the device, in the case of an electrical short, or lead it to a slower death as corrosion grows on the electronic components and eventually renders the device non-functional.

Neutron radiation is used during quality assurance in electronics and semiconductor manufacturing to detect any amounts of moisture that may have become trapped within the device during the bonding process or before the device was fully sealed and packaged. Moisture that becomes trapped in an electronic device can cause immediate bricking of the device, in the case of an electrical short, or lead it to a slower death as corrosion grows on the electronic components and eventually renders the device non-functional.Neutron imaging is useful for manufacturers of electronic devices of all kinds, especially ‘rugged’ devices. Electronics for use in the field are made with tough, durable, waterproof casing to protect their delicate circuitry from physical shock, temperature and humidity extremes and, of course, water. Developing rugged devices is a process of trial and error. When testing these devices, neutron radiation can be used to find evidence of water leaking through the outer casing and leaving residue on the circuitry within.

Using neutrons to inspect bridge structures

Neutron radiation has great potential for use in concrete inspection, though issues with portability have limited its use in the past. Concrete is a relatively porous material that water can penetrate; reinforced concrete, which has material such as rebar embedded within so as to improve the structure’s low tensile strength and ductility, can become weakened by water exposure. Though the materials in concrete have high neutron cross-sections, water has an even higher cross-section, which helps NDT professionals in civil infrastructure assess the service life and durability of reinforced concrete structures.

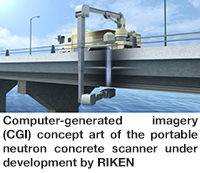

In Japan, NDT professionals are developing a means to use neutron generators to assess water damage to civil infrastructure, especially bridges. Water damage or, more specifically, saltwater damage, is of special concern in the coastal areas of the island nation. Saltwater is much more corrosive than freshwater. When saltwater penetrates the concrete structures of roads and bridges, the salt will remain behind and may corrode the reinforcing material within the concrete, weakening the entire structure. Early in 2019, Japanese engineers developed a compact neutron source that could be used to non-destructively inspect the nation’s infrastructure for salt incursion and the resulting corrosion. They continue to work on further miniaturising the technology so it can be conveniently used in the field.

In Japan, NDT professionals are developing a means to use neutron generators to assess water damage to civil infrastructure, especially bridges. Water damage or, more specifically, saltwater damage, is of special concern in the coastal areas of the island nation. Saltwater is much more corrosive than freshwater. When saltwater penetrates the concrete structures of roads and bridges, the salt will remain behind and may corrode the reinforcing material within the concrete, weakening the entire structure. Early in 2019, Japanese engineers developed a compact neutron source that could be used to non-destructively inspect the nation’s infrastructure for salt incursion and the resulting corrosion. They continue to work on further miniaturising the technology so it can be conveniently used in the field.Using neutrons in other fields

Non-invasive, non-destructive means of inspection, such as neutron imaging and neutron activation analysis, are useful not just to NDT professionals but also to researchers in other fields. For example, 3D neutron tomography was recently used to great effect to map the flow of water through a plant’s roots. Neutrons and their unique affinity with water have also helped scientists unlock the mysteries of how tempering chocolate works and what makes limoncello cloudy by helping them examine these materials on a molecular level.

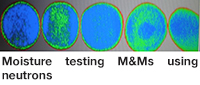

Non-invasive, non-destructive means of inspection, such as neutron imaging and neutron activation analysis, are useful not just to NDT professionals but also to researchers in other fields. For example, 3D neutron tomography was recently used to great effect to map the flow of water through a plant’s roots. Neutrons and their unique affinity with water have also helped scientists unlock the mysteries of how tempering chocolate works and what makes limoncello cloudy by helping them examine these materials on a molecular level.Soon after Mars began producing pretzel M&Ms, customers began to complain that the candy was turning stale very quickly. Food goes stale due to exposure to moisture, so a few neutron imaging professionals ran an experiment in which quantities of M&Ms were parcelled out in various environments and imaged after a set period of time, comparing the results to a control group. What the team discovered was that M&Ms of certain colours turned stale more quickly than others; it was determined that certain dyes were letting more moisture into the chocolate and pretzel within than others.

The past (and future) of neutrons in NDT

Neutron imaging, the major usage of neutron radiation in the field of NDT, was developed within the same decade as the discovery of the neutron in 1932. However, sources of neutron radiation were hard to come by and it was not until the 1950s that technology progressed to the point at which neutron images could actually provide a degree of clarity that made them useful for industrial NDT.

However, easily accessible sources for neutron radiation remained scarce. While X-ray technology improved by leaps and bounds over the decades following the discovery of X-rays and was quickly adopted by medical professionals and industrial NDT professionals, neutron radiography and neutron activation analysis lagged far behind. In order to be performed in a timely fashion, neutron radiography requires a source with a high neutron flux or number of free neutrons produced per second. The necessary neutron flux has, until recently, been achievable only through the use of nuclear fission reactors available for research and commercial use, radioisotopes that emit massive number of neutrons such as californium-252 or via massive accelerator facilities such as the Spallation Neutron Source at Oak Ridge National Laboratory or SINQ at PSI.

Portable neutron sources, which are electrically driven and rely on fusion reactions, have existed for decades, but they have low neutron fluxes that render them impractical for neutron imaging and for NDT in the field. However, over the past few years, progress has been made in the realm of electrically driven and fusion-based reactors that is making neutrons more accessible for NDT professionals than ever before.

The compact neutron source being developed by engineers at RIKEN in Japan to test for salt corrosion, for instance, will make it possible to use neutron activation analysis on infrastructure without the need to remove samples of concrete from the structure and test them in a laboratory. US-based nuclear technology company Phoenix LLC has spent years developing compact, high-flux neutron generators that can be used for neutron imaging, among other uses for neutrons in NDT. Phoenix recently broke a record for neutrons created by a sustained nuclear fusion reaction using its neutron source and recently opened the Phoenix Neutron Imaging Center (PNIC), a first-of-its-kind imaging facility that will provide both neutron and X-ray imaging and computed tomography without requiring the use of a fission reactor.

The compact neutron source being developed by engineers at RIKEN in Japan to test for salt corrosion, for instance, will make it possible to use neutron activation analysis on infrastructure without the need to remove samples of concrete from the structure and test them in a laboratory. US-based nuclear technology company Phoenix LLC has spent years developing compact, high-flux neutron generators that can be used for neutron imaging, among other uses for neutrons in NDT. Phoenix recently broke a record for neutrons created by a sustained nuclear fusion reaction using its neutron source and recently opened the Phoenix Neutron Imaging Center (PNIC), a first-of-its-kind imaging facility that will provide both neutron and X-ray imaging and computed tomography without requiring the use of a fission reactor.All of the entities working on developing stronger, more convenient sources for neutron radiation are working towards the same goal – to make neutron-based methods of inspection more easily usable and readily available to the world. Though neutron imaging and neutron activation analysis have existed for decades, neutron-based methods of non-invasive inspection are still immature in many ways. Neutrons still have many unexplored and under-explored novel applications within the realm of NDT. By developing new technologies to provide neutron-based tools to researchers and NDT professionals, we can further explore the practical possibilities of neutrons in research and development, quality assurance, failure analysis, infrastructure stress testing and beyond.

https://phoenixwi.com