In-service inspection of surface scabs

08/05/2017

The NDT industry has long required an inspection technique that accurately determines the condition of pipe surfaces below formed scabs. The latest pulsed eddy current (PEC) technology provides such a solution and can be applied while pipes are still in service…The objective of this qualification is to establish the capabilities of a system specific to quantifying the remaining wall thickness below surface-forming scabs, something that any robust system must be capable of doing. The Eddyfi Lyft®, a high-performance pulsed eddy current solution, is one such system.

What is Lyft?

This latest system has state-of-the art technical features and offers real-time C-scan imaging. Data acquisition is rapid, with up to 15 readings per second. The system’s functionality includes both grid mapping and dynamic scanning modes. It is also portable and user-friendly, with cables that extend up to 65 ft.

Inspection sample

The sample selected for inspection is a spool containing large areas of surface scabs, as can be seen in the image to the right.

The sample selected for inspection is a spool containing large areas of surface scabs, as can be seen in the image to the right.The area to be inspected was gridded ‘A’ to ‘I’ on the circumferential axis and ‘1’ to ‘28’ along the longitudinal axis.

The next steps were as follows:

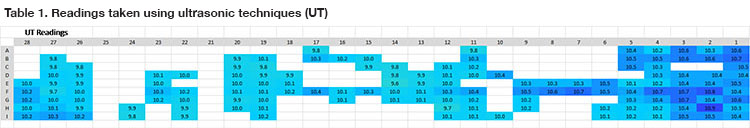

- The material thickness was measured using ultrasonic techniques (UT) in the areas where the surface condition has not been affected with surface oxidisation and a table was created (Table 1)

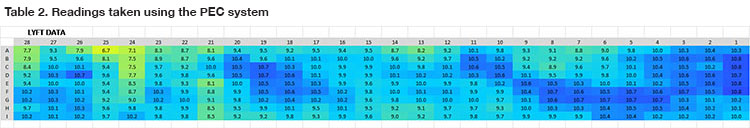

- Readings were also taken with the pulsed eddy current (PEC) system and a table was created (Table 2). Readings could be taken in every location

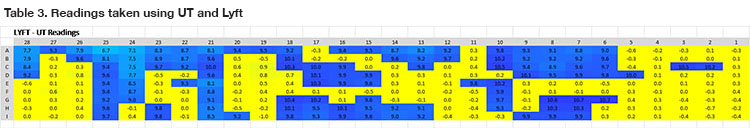

- A third table was then created by subtracting the UT readings from the Lyft readings (Table 3).

The results in Table 3 show where both a UT and Lyft reading were taken. The readings have an average variation of 0.4 mm, with the highest reading giving a variation of 0.9 mm. These areas are identified as white in Table 3.

The shaded areas in Table 3 indicate where no UT data was taken (so where a scab is present on the surface).

As the variation between UT and Lyft readings are consistent on the nominal wall thickness areas, some confidence in the accuracy of the readings below the scabs can be taken.

Conclusion

The qualification was conducted in a timely manner from start to completion. It identified that the Lyft successfully measured thicknesses in the same region where nominal wall thickness was present (no surface scabs present). This provides a degree of confidence in the readings taken from the other areas of the sample. Limitations of the PEC system always need to be considered with the results provided beneath the scabs.

The results of this research demonstrated a good foundation to allow further work to be conducted. Future work will involve the removal of scabs, allowing for remaining wall thickness to be measured with ultrasonic techniques and feeding this back to what the PEC system measured. Field trials will also be carried out, thus building confidence in the initial results of this study. Ultimately, the aim is to gain a better understanding of the relationship of surface scabs to wall thinning below the scabs.

www.tracoilandgas.com