Computed radiography to increase efficiency in heat exchanger inspection

08/09/2020

OK CONTROL Srl, a service company located in Schio, Italy, has always strived to make quality an ultimate priority since its beginnings in 2002. OK CONTROL is capable of performing visual, penetrant, magnetic, ultrasonic and radiographic testing inspections, both in-house or on-site at the customer’s location.Over the years, OK CONTROL has specialised in a number of very specific and unique applications and through this has developed techniques in which digital radiography plays a crucial role.

For example, a customer manufacturing cooling systems used in nuclear plants requested that OK CONTROL inspect heat exchangers, which contain tubesheets. The tubes themselves ranged from 18 mm to 28 mm in diameter and it was the tube-to-tubesheet welds that required inspection.

The solution developed by OK CONTROL could only be made possible using imaging plates (IPs) or traditional films, as they are flexible and can be customised in size and shape.

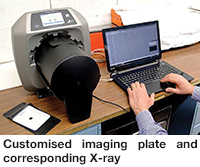

The solution developed by OK CONTROL could only be made possible using imaging plates (IPs) or traditional films, as they are flexible and can be customised in size and shape.OK CONTROL used a rod anode for panoramic X-ray in combination with customised IPs, which allowed the rod anode to be inserted through the IP and then inside the tube. Since the X-ray source also emits radiation backwards, the IP is able to expose and the welds around the rod anode can be analysed. This is the only way to inspect these kinds of weld and using computed radiography (CR) improved the efficiency considerably due to the reduced exposure time and an extremely fast workflow. Furthermore, since the inspector obtains the image directly by on-site scanning of the IP, CR allows the customer to receive quick feedback.

Through the use of the DÜRR NDT CR 35 and HD-CR 35 systems, OK CONTROL has increased its efficiency drastically, with the number of projects also increasing. Umberto Zambotto, Founder of OK CONTROL, commented on what he appreciates about the CR systems: “The speed of execution, monitored area limitation, no production stops, no use of chemical products, immediate results, excellent image quality and of course the productivity: we performed digital X-ray with CR on tube-to-tubesheet welds at a speed of 600 joints per day.”

www.okcontrollinondistruttivi.com