Computed radiography ideal for flash X-ray applications

29/09/2025

Fisica is a world-leading manufacturer of flash X-ray systems that address a wide variety of industrial and research applications. Flash X-ray is used when it is necessary to examine fast-moving, visually obscured objects, or to observe the effects of an event or impact that is too fast for the human eye.

| ||

| The Scan-X system offers a mobile and rugged solution for demanding NDT environments |

Fisica’s flash X-ray systems produce a single, extremely short and high-powered X-ray pulse that can be used to effectively stop the motion of a fast-moving object and allow its internal structure to be imaged and analysed. X-ray pulser voltages of 150 kV, 300 kV, 450 kV and 1.2 MV are available, with pulse widths from 20 ns to 70 ns, which offer the flexibility to address a wide variety of applications for both commercial and government entities.

Past applications have included the inspection of helicopter blades while spinning, munitions in flight, impact events such as car crashes and bulletproof vests being struck, and even evaluation of space shuttle tiles being struck by hypervelocity objects.

| ||

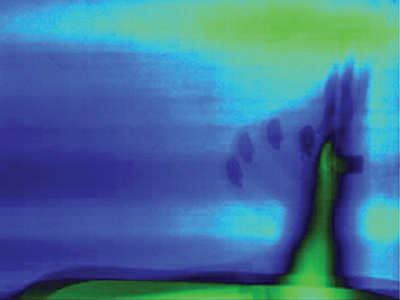

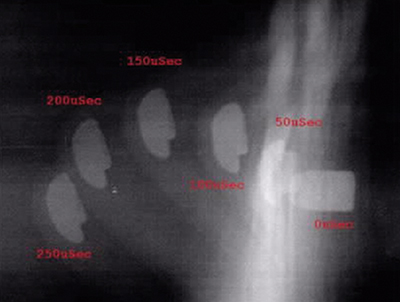

| Imaging example: the images above show a sequence of six exposures, taken 50 µs apart, on a single CR plate, of a 30-06 bullet (moving right to left) striking a bulletproof (Kevlar) vest. The exposures were created using 150 kV pulsers. Each X-ray pulse lasted 70 ns |

Fisica usually uses computed radiography (CR) to capture images because of its numerous advantages over film and digital radiography (DR). Specifically, the time to acquire an image is much shorter than it would be using film and no darkroom or chemicals are required.

This means that imaging can be carried out in the field and the results are available almost immediately. In addition, digital images are easily manipulated to enhance details and make accurate measurements of objects in the image. CR plates, unlike films, also accept multiple X-ray exposures.

Computed radiography has advantages over DR in typical flash X-ray applications because the image capture medium is often at risk from shock or high-velocity debris, may need to be bent and shaped to fit a specific need and always needs to have a very high sensitivity due to the short X-ray pulses. The imaging plates (IPs) used in CR are extremely inexpensive compared to a digital detector array (DDA), are more rugged and are available in a wide variety of sizes, sensitivities and resolutions.

Fisica uses both the Dürr NDT ScanX Discover HC and HR CR scanners to digitally capture X-ray images and then display them digitally on a monitor for evaluation.

ScanX HC is said to be ideally suited for this application because of its ability to deliver high-contrast images and the flexibility given to the user to directly manipulate and control the internal functions of the scanner. For example, the photomultiplier tube (PMT) inside the scanner can be explicitly controlled to provide the maximum amplification of the image captured on the imaging plate. Flash X-ray pulsers generally produce lower X-ray doses than standard NDT applications, which in turn means a relatively low exposure on the imaging plate. Having the ability to vary the PMT to amplify this faint signal is key to capturing good-quality images. This is only possible using the superior signal-to-noise ratio of the ScanX HC PMT, it is claimed.

Some flash X-ray applications involve very fast-moving objects and/or longer objects. To effectively image these, long imaging plates are often used to better image the objects in flight. The ScanX HC can scan imaging plates up to 14" (35 cm) wide and imaging plates up to 60" (150 cm) long are routinely scanned by the ScanX HC. Under extreme circumstances, plates that are over 100" (250 cm) have been successfully scanned.

In addition to the ScanX CR system, Dürr NDT offers a variety of CR, DR and software products to the non-destructive testing (NDT) industry. Dürr NDT is proud to partner with Fisica and to provide solutions that address the unique requirements of flash X-ray applications.