TWI Yorkshire opens doors to new generation of engineers

14/08/2008

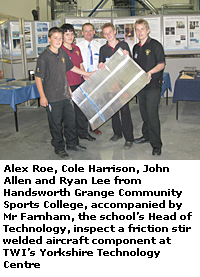

TWI's Technology Centre on Rotherham's Advanced Manufacturing Park has opened its doors to a potential new generation of engineers and technologists, hosting visits by local students from nearby Handsworth Grange Community Sports College and a second group from Sheffield Hallam University organised by The Industrial Trust.

TWI's Technology Centre on Rotherham's Advanced Manufacturing Park has opened its doors to a potential new generation of engineers and technologists, hosting visits by local students from nearby Handsworth Grange Community Sports College and a second group from Sheffield Hallam University organised by The Industrial Trust.TWI's Yorkshire Technology Centre, a state-of-the-art research facility dedicated to developing new materials joining and processing techniques, also provides the high quality professional training vital to ensuring that businesses establish and maintain a competitive edge in global markets. TWI Yorkshire thus presented an ideal venue for the students to learn not only about the latest technical developments in materials science but also how they could take up careers in engineering and play a part in helping drive forward the region’s manufacturing industry.

After hearing about TWI's history and the wide range of processes and products that have benefited from the application of advanced technical know-how, the students were given a tour of the engineering laboratory where they were able to see for themselves the latest developments in manufacturing.

A process which gained particular attention was the use of lasers to grow engineering components from metal powder rather than the traditional means of machining them from solid ingots. The new process is far less wasteful of material, using only the minimum amount of metal and energy required to create a part and producing no machining scrap; cost and environmental benefits that were quickly recognised by the students.

Equally impressive were TWI Yorkshire's Friction Stir Welding capabilities, a revolutionary metal joining process used to fabricate parts as diverse as space rockets, high-speed trains and the new Eclipse jet aircraft.