Industry-first LiDAR sensor drone trial conducted at Bacton Gas Terminal

02/08/2021

Working in collaboration, leading operations, maintenance and asset integrity contractor Bilfinger and leading commercial drone providers RUAS and Heliguy have completed an industry-first trial of pioneering L1 LiDAR sensor drone technology at Shell UK’s Bacton Gas Plant.

Working in collaboration, leading operations, maintenance and asset integrity contractor Bilfinger and leading commercial drone providers RUAS and Heliguy have completed an industry-first trial of pioneering L1 LiDAR sensor drone technology at Shell UK’s Bacton Gas Plant.On behalf of DJI, one of the world’s largest drone manufacturers, RUAS approached Bilfinger to source a client that could facilitate a UK-first drone inspection with its new light detection and ranging (LiDAR) sensor, the DJI Zenmuse L1.

Mounted to DJI’s latest commercial drone platform, the Matrice M300 RTK, the L1 provides real-time 3D data, efficiently capturing the details of complex structures. This comprehensive data provides highly accurate measurements for digital twin creation to enable predictive maintenance and inspection. Dr David Hall, Operations Director at Bilfinger Salamis UK, said: “We’re delighted to have collaborated with Shell UK to support the first commercial trial of this innovative technology. Bilfinger is committed to identifying and applying technical innovation with a focus on exceeding client and market expectations through investment in our people and in research and development.

“This trial has demonstrated that the Zenmuse L1 could revolutionise digital twin creation and integrity planning in the energy industry.”

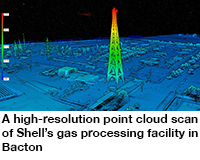

Erwin Loonen, Shell Projects and Technology, said: “Shell believes that digitalisation enables higher asset efficiency and lower human exposure. Bilfinger and partners have successfully executed a high-resolution point cloud scan of Shell’s gas processing facility in Bacton, using state-of-the-art equipment.

“The information gathered will be stored as a digital twin in our cloud environment, improving the situational awareness of our staff and contractors, enhancing logistic optimisation and enabling the use of advanced analytics to support our asset integrity strategy.”

As incumbent operations and maintenance contractor to Shell UK, Bilfinger delivers a number of advanced inspection and integrity services at Bacton Gas Plant, located 20 miles from Great Yarmouth.

Built and commissioned in 1968, Bacton is a hydrocarbon gas processing plant of strategic national importance supplying up to a third of the UK’s gas supply, as well as importing and exporting gas from Europe.

Built and commissioned in 1968, Bacton is a hydrocarbon gas processing plant of strategic national importance supplying up to a third of the UK’s gas supply, as well as importing and exporting gas from Europe.Tim Harris, Director of Operations and Compliance at RUAS, said: “The Zenmuse L1 revolutionises datasets, capturing up to 328,000 points of interest per second and generating true-colour point cloud models in real time with renders of reconstructions accurate to within 5 mm. This structural information is invaluable for creating maintenance strategies.

“This trial has shown us that a complex, large site like Bacton could be surveyed in around two hours, providing huge cost savings for operators over traditional inspection methods.”

RUAS has utilised the M300 RTK extensively over the last few months and the L1 trial was further proof of the drone’s capabilities, which include up to 55 minutes of flight time and the ability to carry up to three payloads simultaneously.

Mr Harris added: “When used in conjunction with the L1 sensor, or the DJI Zenmuse P1 45MP full-frame photogrammetry sensor, we have been able to obtain extremely useful data for our clients using the M300, even in difficult environments.

“When used in conjunction with these sensors, the endurance of the M300 RTK really does make a difference when flying over larger areas, allowing higher speed while still achieving quality imagery. This, in turn, reduces our time on site and allows us to operate more efficiently.”

www.salamis.bilfinger.com