Process monitoring for press-hardening production lines from AP&T

20/03/2023

When metal manufacturer AP&T needed an automated solution to monitor the heat distribution during the shaping and pressing of vehicle parts, it turned to Termisk Systemteknik. The answer was a non-contact temperature monitoring solution using thermal imaging cameras from Teledyne FLIR.

Sweden-based AP&T supplies production solutions to manufacturers worldwide, including automation, presses, furnace systems and tooling, for the manufacturing of press-hardened vehicle parts for the automotive industry.

Car manufacturers are using lighter sheet materials, such as aluminium and thinner steel, to form robust parts for car body frames. When pressed, these lighter materials still produce a strong body frame that meets the required safety standards, without adding unnecessary weight to the build of a car, which can drain both fuel and battery life.

AP&T needed a solution to measure and monitor sheet materials before and after pressing. It is necessary to guarantee even heat distribution from the furnace before the sheets are pressed and an exact placement of the sheets, as well as ensuring that there are no hot spots after the sheets are cooled in the press tool.

If any of these three conditions are not met, the required mechanical properties of the safety-relevant components will not be reached. This causes rejected parts, wasted materials and additional manufacturing time. Also, the press tool itself might be

damaged.

In order to save car manufacturers time and money by preventing defect-pressed parts, AP&T reached out to Swedish thermal imaging integrator Termisk.

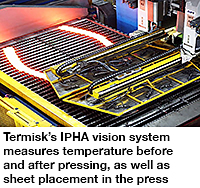

Termisk designed an infrared press-hardening analysis (IPHA) vision system that can measure the three main factors affecting sheet pressing quality: temperature before and after pressing and sheet placement in the press.

Using Teledyne FLIR thermal imaging cameras mounted to the sides of press machines, the IPHA system measures the temperature of metal sheets using the Teledyne FLIR A70 smart sensor camera (previously A315) or the Teledyne FLIR A615 camera, depending on the required image quality.

The IPHA system features a Teledyne FLIR thermal imaging camera on each side of the press with wide-angle lenses. The set-up ensures the temperature is measured accurately for the whole surface area of the 3D-shaped sheet material.

The process is automated, so once pieces are inside the press, the press-line controller system signals to the IPHA system to take an image and analyse it. Once the positioning and temperature are determined as being acceptable, a signal is sent back to the press line to proceed.

Similarly, it then measures the sheet temperature and inspects heat distribution after pressing, once the shaped part is cooled. Unless there are any issues or alarms raised, there is minimal interference needed from an operator.

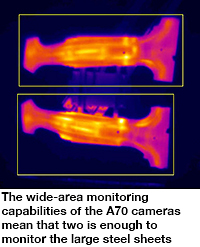

The high-resolution thermal images make it quick and easy to identify hot spots and measure the areas where the material has not reached the correct temperatures.

The system makes tool pressing and changeovers quick and simple too. The software allows manufacturers to preset temperature analysis parameters for the different pressing tools used. This allows the IPHA system to reconfigure quickly during changeovers.

Teledyne FLIR’s A70 image streaming camera is said to be ideal for advanced condition monitoring. In this case, the Teledyne FLIR A70 is capable of monitoring the temperature and heat distribution on steel sheets, even with raised parts, using non-contact temperature sensors.

The wide-area monitoring capabilities of the A70 cameras mean that two cameras (one on each side of the press) is enough to monitor the large steel sheets. The cameras will alert operators to any issues so they can investigate and rectify them immediately to prevent wasted materials and additional production time.

For sites that require higher thermal imaging quality, the Teledyne FLIR A615 camera is a powerful alternative to the A70 in IPHA. Offering the same non-contact temperature measurement, the A615 provides higher accuracy and can detect temperature differences even at long distances.

Termisk has now implemented at least 40 IPHA systems for pressed part manufacturer AP&T worldwide. The thermal imaging solution can be installed on new lines or retrofitted to existing lines.