Peak NDT receives Queen's Award for Enterprise - Innovation 2011

09/05/2011

The Queen’s Awards for Enterprise are Britain’s most coveted and prestigious awards for business performance. On 21 April 2011, on the occasion of the Queen’s birthday, Peak NDT celebrated at its premises in Derby as it was announced that the world leading developer and manufacturer of conventional and phased array ultrasonic inspection equipment is among the elite group of companies to have won a Queen’s Award.

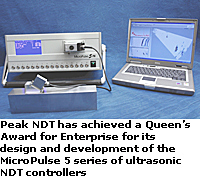

The Queen’s Awards for Enterprise are Britain’s most coveted and prestigious awards for business performance. On 21 April 2011, on the occasion of the Queen’s birthday, Peak NDT celebrated at its premises in Derby as it was announced that the world leading developer and manufacturer of conventional and phased array ultrasonic inspection equipment is among the elite group of companies to have won a Queen’s Award.The announcement in the London Gazette was as follows: ‘An Innovation Award is made to Peak NDT for the design and development of the MicroPulse 5 series of ultrasonic NDT controllers’.

Co-founder and Operations Director of Peak NDT, Andy Whittle, said: “We are thrilled to be receiving this award as recognition of the excellent and sustained innovative work that has been put in by all of the staff at Peak NDT over the last few years. The Queen’s Awards are extremely prestigious and highly recognised both here in the UK and internationally. Winning the award will provide a significant boost to the company’s profile and reputation, as well as further raising awareness of our world-class products.

“Worldwide, phased array inspection techniques are becoming increasingly utilised in a broader range of inspection applications, providing large and continuing opportunities for innovation and growth. These applications are also driving demands for increased capability and continued product innovation. In the near future, we will be launching a further version of the MicroPulse 5, specifically optimised for full matrix capture techniques (MicroPulse FMC), and we are continually working to increase the number of array channels available, with already the possibility of controlling 1024 active elements. We have purposefully developed our equipment in a modular manner that enables customers to increase rapidly their array channel capability. Our approach to an open command and data structure gives the customer complete freedom of choice in the user interface (software) to control the instrument, as well as maintaining compatibility with existing industry standard software packages.”

Technical Director, Alison Whittle, said: “Winning this Queen’s Award will provide all of us at Peak NDT a significant boost in confidence and additional impetus and encouragement to build on the successes that we have been achieving as a team over recent years.”

Peak NDT is a world leading designer and manufacturer of conventional ultrasonic and phased array inspection control equipment used in advanced engineering sectors such as aerospace and power generation. In 2003, backed by a DTI SMART award, the company launched the development of its MicroPulse 5 series of controllers and from the outset the aim was to develop a highly capable and flexible instrument that would be at the forefront of the NDT industry. The initial phase of development was completed in 2006, with systems entering the market at this time. As well as being the principal system for the automated ultrasonic inspections carried out by EDF Energy on all the UK’s civil nuclear power generation plant, MicroPulse 5 systems are now in regular use across a number of other industry sectors with a range of leading NDT inspection companies: at aerospace OEMs and overhaul and repair companies; within high-value manufacturing production inspection systems; and are being utilised at a number of world leading research institutes. Peak NDT prides itself on its engagement with its customers, developing flexible solutions to meet their current needs whilst working closely with them to identify their future potential requirements. As such, Peak NDT is continually investing in and developing further the capability of its equipment. The MicroPulse FMC is a direct result of this.

As a consequence of the sustained business growth, Peak NDT has recently moved into new purpose-built facilities in Derby, providing the company with increased development and production capacity. All of Peak NDT’s products are designed and manufactured at these facilities.

www.peakndt.com