New subsea technology revealed by industry leaders

06/11/2008

AGR Field Operations and flexlife Ltd have formed a partnership to provide a ground-breaking new application which could revolutionise the subsea sector of the oil and gas industry.

AGR Field Operations and flexlife Ltd have formed a partnership to provide a ground-breaking new application which could revolutionise the subsea sector of the oil and gas industry.The application, developed over two years, has a 100% success rate and will help prevent the failure of flexible risers and flexible flow lines, thereby minimising lost production and associated environmental impact of a leak. The daily cost of lost production resulting from a riser failure has been estimated at between €1m and €3m.

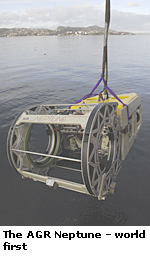

Aberdeen-based flexlife devised the patented solution to scan flexible risers in situ and detect annulus flooding anywhere along their length – the first time in the 40 year history of unbonded flexible pipe that this has been achieved – while AGR Field Operations has the ROV capability to deliver it through the Neptune system.

AGR Field Operations, a division of the AGR Group, is a global provider of a wide range of services to the oil and gas industry. The business focuses on the management systems, procedures and state-of-the-art technologies to attain and maintain prescribed levels of technical integrity of oil and gas industry assets.

"AGR Field Operations is proud to have developed the ROV-deployable Neptune system, a world first that can deliver a range of truly innovative subsea inspection solutions," said AGR Field Operations Executive Vice President Åge Landro.

"AGR Field Operations is proud to have developed the ROV-deployable Neptune system, a world first that can deliver a range of truly innovative subsea inspection solutions," said AGR Field Operations Executive Vice President Åge Landro."The joint objectives of AGR Field Operations and flexlife are to field the first subsea inspection application that can be used for the reliable, in-situ annulus examination of flexible risers and flowlines for the detection of flooding and to reduce or eliminate hydrocarbon leaks and spillage from offshore FPSO oil production facilities due to a breach of flexible risers or flexible flowlines resulting from in-service failure."

flexlife director Carl-Petter Halvorsen said: "This is the first time it has been possible to scan any flexible pipe in situ without access to the end fitting, meaning any potential failures can be identified and dealt with more quickly than was possible previously. Neptune is fast, reliable and can go down to 6,000 m, so the technology can go anywhere in any environment meaning the potential cost savings and environmental benefits are immense.

"flexlife was established to create solutions to the most common failures in flexible risers. The technology is a step change for the industry and we are delighted to be working in partnership with AGR Field Operations to enable us to deliver solutions immediately for clients globally. We believe that the Neptune system and development of this technology is such a breakthrough that the traditional approach of vacuum testing might be rendered obsolete."