Keeping the lights on and preventing failures with the FLIR Si124

23/11/2022

SPI Inspections, which operates in Canada and China, provides its customers with utility system and infrastructure inspections, relying on the company’s extensive experience in the field and advanced inspection technology. The team uses unmanned aerial vehicles (UAVs), FLIR thermal cameras and other high-tech equipment to deliver qualified inspection services, independent verification of construction standards and monitoring of power systems.

Recently, the team at SPI Inspections test-ran the new FLIR Si124 acoustic imaging camera. Built with 124 microphones, the Si124 produces a precise acoustic image that visually displays ultrasonic information in real time on top of a digital camera picture. This allows the user to visually pinpoint the source of the sound.

The founders of SPI Inspections have more than 100 years of combined experience working with utility systems, from building power lines to inspecting substations. “We have been around the block a few times,” said Elton Hunter, Field Manager at SPI. “Our background is basically power, from where it is made in the generating facility to where the meter is; either the meter on your home or the meter on your business.”

“We have really assisted our customers,” he continued. “Our goal is to make their systems work better, safer and to be more reliable.” The team at SPI Inspections found the FLIR Si124 to be an invaluable asset in detecting partial discharge, a sign of approaching or imminent failure in power infrastructure.

The journey of electricity, from power plant to lightbulb, presents plenty of opportunities for failure if infrastructure is not properly maintained. SPI uses its extensive experience to recognise when an element needs maintenance, aided by advanced technology. “We bring a lot of technological tools to the trade,” Elton continued.

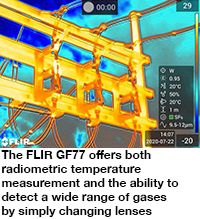

Among the tools in their arsenal is the FLIR GF77 gas detection camera, which allows sulphur hexafluoride (SF6) leaks to be spotted in electrical installations, as well as for hot spots to be detected. The GF77 is a multi-use camera that can detect a range of gases just by changing out the lens. When equipped with an HR lens, the camera can visualise sulphur hexafluoride, while an LR lens allows the camera to see methane, ethylene, ammonia and other gas emissions. The camera is also calibrated for temperature, so it functions as a standard thermography camera used to reveal a wide range of utility issues.

Having relied on FLIR gas detection cameras for previous inspections, the SPI team was excited to get its hands on the Si124 to see what it could do. Though acoustic imaging cameras are often used to locate pressurised leaks in compressed air systems, the Si124 is also a very effective tool for detecting partial discharge in high-voltage systems.

Partial discharge, caused by a breakdown in electrical insulation, can be detected when the air around the breakdown becomes ionised, creating a phenomenon called ‘corona’. Corona can be quickly detected using acoustic imaging and is identified by a ‘meatball’ of sound in the image. “For us, that is invaluable,” said Elton.

The team had previously been using ultraviolet technology to detect corona and was pleased to find that the Si124 achieved about the same result for a fifth of the price. “The Si124 basically does the same job and it is very easy to use,” explained Brett Fleming, Corporate Manager at SPI Inspections.

Because so much of their work is carried out in the field, it is important to the team at SPI Inspections that their tools are ready for the job. “It is very user friendly,” said Elton about the Si124. “Within half a dozen hours, we were very confident working with it.”

“The camera has wonderful clarity for us in the field,” Elton continued. He said his team appreciated the quality of the images, ease of download to a laptop or the cloud and the functionality of the user interface. “We are guys that have been in construction for 40-plus years; we have got arthritis and big swollen hands from hitting hammers and stuff. The user interfaces – the keys and the touch boards – are very user friendly. We found them very easy to work with.”

The Si124 made it much easier to spot failures from the ground. During their test run of the camera, they found a failure on a power line 220 ft up in the air, which is a difficult issue to detect. “With our drones we could, but we wouldn’t have known where to look,” said Elton. “Because of our field experience we were able to pick it out and zoom in on it, then we knew that there was a bit of a problem up there.”

“That’s a US$25 million failure on a line that is only five years old,” he remarked. With the Si124 they were able to catch the problem early, before the cost to fix it became nearly that high.

Electrical substations and other utility infrastructure present numerous hazards for workers and inspectors. When the team confronted a particularly dangerous area inside the substation where a capacitor bank had come down, they were required to stay outside the chain-link fence enclosing the area. They were pleased to find that the Si124 could look through the fence to assess the situation.

“We were able to walk right up and we could look through the chain-link fence. Because there are 124 microphones on the front of the camera and then one little tiny camera, that camera was able to look right through that two-by-two inch square and keep our people safe, which is a huge advantage for us being in the field,” Elton explained.

SPI’s goal during inspections is to catch issues before they are allowed to escalate too far. Spotting partial discharge and corona early with tools like the Si124 helps them to anticipate any failures and keep the lights on for their clients. “It allows us to preemptively prognosticate what is happening in our power line,” said Elton. “So instead of there being a catastrophic failure and then an outage and a repair, we can go in ahead of time and we can tell them: ‘You are going to have a problem with this if you do not fix it.’”

Unplanned outages can be prevented with regular inspection and maintenance. “If we do our jobs right, nobody ever knows we are out there. The customer does not know we are there; we do our job, we make recommendations and then through planned outages or regular maintenance they can repair something.”