Emerson ensures product integrity with portable, high-resolution digital X-ray scanner

27/11/2025

Emerson was founded in 1890 in St Louis, Missouri, USA, as a manufacturer of electric motors and fans. Over the past 100-plus years, it has grown from a regional manufacturer into a global technology solutions powerhouse. Emerson has many subsidiaries including Emerson Automation Solutions, which was founded in 2015.

FR Tecnologías de Flujo (TF) Emerson, based in Chihuahua, Mexico, is part of Emerson Automation Solutions. TF manufactures measurement instruments that are used in a wide range of industries, such as flow measurement, density and viscosity instruments. Some of the critical industries they serve include food and beverage, life sciences, oil & gas and refining.

Welding is a core competency at Emerson and nearly all the measurement instruments FR Tecnologías de Flujo manufactures have pressure retaining welds that require non-destructive testing (NDT). The diameters of the welds range from 3 mm to 914 mm with wall thicknesses ranging from 0.2 mm to 38.4 mm.

In the past, FR Tecnologías de Flujo utilised analogue film to perform radiographic inspection. In 2010, Emerson Automation Solutions started to investigate alternatives to film radiography and, during this investigation, it came across the versatile HD-CR 35 from Dürr NDT.

The HD-CR 35 is said to be the most flexible and advanced computed radiography (CR) scanner on the market today, with the ability to provide the highest resolution images in the industrial radiography industry, it is claimed. In addition, due to its unique TreFoc technology, which offers an adjustable laser spot size, it can also provide high-contrast images when necessary. On top of this, the HD-CR 35 boasts the smallest footprint of any CR scanner currently available on the market, it is claimed, which makes it completely portable.

A demonstration of its capabilities was requested and it was found that digital radiographs acquired on the Dürr HD-CR 35, using the powerful image acquisition software D-Tect, produced images with better contrast sensitivity, which allowed greater variances in material thickness to be seen because digital radiography has a much higher dynamic range when compared to film. It was also noticed that exposure times decreased and it took much less time to scan an imaging plate than it took to process film. Based on the results of the demonstration and input from other Emerson locations, which had already been using the HD-CR 35, FR Tecnologías de Flujo decided to purchase a scanner and software. After making the transition from film to CR, TF noticed immediate improvements to throughput times and the evaluation process.

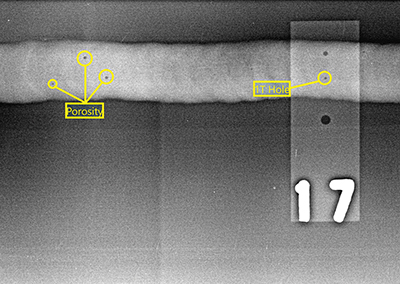

One example of how digital imaging has helped FR Tecnologías de Flujo with the evaluation process can be seen in Figure 1. In the past, while using film, the 1T hole in the image quality indicator (IQI) along with the three small pores in the groove weld may not have been detected. Now, however, it is possible to increase the probability of detection by using digital imaging filters built into the D-Tect X software along with adjusting the brightness and contrast.

| ||

| Figure 1. With film, the 1T hole in the IQI along with the three small pores in the groove weld may not have been detected |

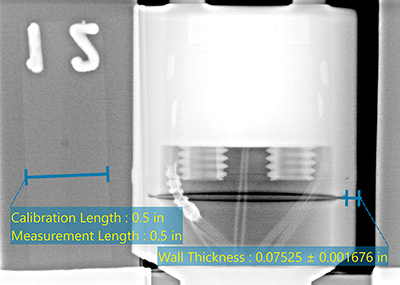

Then, using the powerful image measurement tools built into the software, it is much easier to measure and evaluate indications. With conventional radiography, inspectors needed to use magnifying glasses, or inspection loupes, and a light box in order to evaluate discontinuities. If the contrast sensitivity was poor, an indication might be missed or misinterpreted. In Figure 2, the inspector was able to use measurement tools in the software to precisely measure and evaluate the size of the discontinuities to determine whether the indications were acceptable.

| ||

| Figure 2. Measurement tools in the software precisely measure and evaluate the size of discontinuities |

Another example of how the improved contrast and superior measurement capabilities of the D-Tect X software have improved FR Tecnologías de Flujo’s inspection process can be seen with the inspection of its fork density meter. There is a small weld that is made to join the fork to the rest of the assembly. The amount of penetration is critical on these welds; if there is too much, then there is a possibility of damage to the sensitive electronics just behind the weld joint.

If there is not enough penetration, the weld does not meet design requirements. When using film, measuring the amount of penetration in a profile shot using a magnifying glass or inspection loupes is a tedious process.

Using the zoom magnifying function in the D-Tect X software, the user can simply zoom into a region of interest, as shown in Figure 3. Then, they can use either the wall thickness measurement tool or the line measurement tool to precisely measure the amount of joint penetration.

| ||

| Figure 3. The D-Tect X software allows users to zoom into regions of interest |

Since 2010, FR Tecnologías de Flujo has built three new cabinets and purchased six more HD-CR 35 scanners along with D-Tect X software. The company continues to grow and is in the process of building a new X-ray bunker to help with the backlog and to handle some of the largest instruments it manufactures. It is very happy with the quality of the digital images acquired from the HD-CR 35 scanners but, on top of that, the company has high praise for the customer support it always receives when facing difficulties.

www.duerr-ndt.com