More China successes for USL

19/09/2012

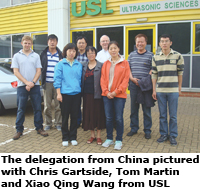

In recent months, delegations of Chinese customers have visited Ultrasonic Sciences Ltd (USL) to carry out pre-delivery acceptance testing on its ultrasonic inspection systems. The most recent group, from AVIC International Aero-Development Corporation in Shenyang, are shown in the picture together with Chris Gartside, Tom Martin and Xiao Qing Wang from USL. The tests were completed and the pre-acceptance document was signed during a nine-day visit. This followed hot-on-the-heels of a visit by a group from a different manufacturer in the same city, which is a major centre for aerospace manufacturing in China.

Both customers have purchased large, multi-axis squirter machines from USL for inspection of complex composite parts, the larger of the two machines having a scan volume of 8 x 2 x 3 m. These are now in transit to China, where they will be installed by USL engineers.

Another six similar machines are already under construction at the USL factory, with three of these also destined for users in China. The others will go to composite manufacturing companies in the UK, The Netherlands and Japan. The first two of these are repeat customers who are already users of similar systems from USL.

Whilst most of the recent USL systems have been for inspection of composites, other applications are not ignored. Currently, USL is building immersion systems for inspection of titanium alloy plate, aluminium alloy plate and semiconductor materials, as well as supplying PC-based ultrasonic instrumentation for original equipment manufacturers.

Other current work includes integration of a USL ultrasonics and thickness measurement package with an industrial robot in a dimensional inspection cell. This follows successful implementation of a robot-based C-scan system for inspection of composite propeller blades in conjunction with an aerospace company in the USA.

www.ultrasonic-sciences.co.uk