OMS completes pipe end measurement surveys for GRTgaz

05/09/2012

Specialist pipe measurement technology company for the oil & gas industries Optical Metrology Services (OMS) Ltd has successfully completed a series of pipe measurement surveys for GRTgaz, France’s largest natural gas operator.GRTgaz operates an

d markets natural gas to the public distribution systems in France and to consumers (industrial customers). GRTgaz operates more than 32,000 km of steel pipelines and 26 compressor stations and is currently implementing the Artere des Hauts de France II project, which involves the installation of pipelines linking an LNG terminal at Dunkerque to the existing

d markets natural gas to the public distribution systems in France and to consumers (industrial customers). GRTgaz operates more than 32,000 km of steel pipelines and 26 compressor stations and is currently implementing the Artere des Hauts de France II project, which involves the installation of pipelines linking an LNG terminal at Dunkerque to the existing gas distribution network in France.

As part of the preparation for this project, GRTgaz contracted OMS to conduct pipe measurement surveys in two separate locations in France: Campagne les Wardrecques and Arques. The objective of the measurement surveys was to identify the proportion of pipes whose out-of-roundness tolerance was greater than 6 mm (ie out of their manufacturing specification), which could later result in pipe fit-up delays and welding issues.

The surveys were carried out in three separate mobilisations during November 2011, February 2012 and April 2012. OMS measured a sample of 450 pipe ends during the first survey, 900 during the second and 108 pipe ends during the third survey. Pipe end dimensions measured included inside diameter, outside diameter, wall thickness and out-of-roundness tolerance (6 mm).

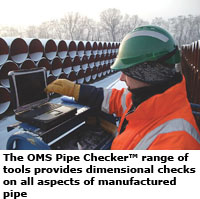

For end dimensioning of pipes, OMS utilised its own automatic Pipe Checker™ laser measurement tool, which is capable of measuring more than 2000 IDs and 2000 ODs. The tool is accurate to 0.05 mm and enables just two OMS staff to measure a minimum of 200 pipe ends in a single shift. This meant less time on site, minimising project delays and costs for the customer and reducing pipe fit-up and welding issues.

Dr Richard Gooch, Director of Technology at OMS, commented: “The pipes were stacked outside in sub-zero temperatures, which presented our two inspectors with logistical challenges. Prior to measurements being taken, the pipe ends had to be cleared of snow, ice, dust and debris, as temperatures dropped as low as minus 15 degrees Centigrade during the first two surveys. We also had to use mobile access platforms in order to provide our inspectors with safe access and a stable working platform for measuring the higher pipes in the stacks.”

OMS inspectors maintained a paper record of all measurements as well as digital measurement data,

which was archived directly to a laptop computer and filed under the pipe number for traceability. The measuring tools were calibrated before measurements were taken and then checked for correct calibration after measuring. Results from all three pipe surveys were presented to GRTgaz, which indicated what proportion of pipe ends were within the 6 mm out-of-roundness tolerance and

which were outside of this specification.

www.omsmeasure.com