Borescope inspection reveals catastrophic jet engine failure

28/08/2018

Following an emergency call to Ashtead Technology, a Skywards Aviation consultant was able to collect the latest borescope inspection technology before flying to Rwanda, Africa, in response to an urgent request for engine inspection. Skywards Aviation is EASA Part 145 approved for borescope inspections according to the Aircraft Maintenance Manual and the requirements of specific service bulletins and airworthiness directives. The company’s capabilities cover over 40 different types of engine and auxiliary power units.

Skywards Aviation is EASA Part 145 approved for borescope inspections according to the Aircraft Maintenance Manual and the requirements of specific service bulletins and airworthiness directives. The company’s capabilities cover over 40 different types of engine and auxiliary power units.On 19 February 2018, a CRJ900 jet experienced difficulties during take-off at Kigali International Airport in Rwanda. The crew suspected that an object had entered one of the jet’s engines, causing potentially serious damage, so the aircraft was grounded and an urgent call was made to Skywards to request internal inspection of the affected engine.

“In these circumstances, it is important for inspection work to be undertaken as quickly as possible,” commented Rob Ward, Managing Director of Skywards. “We knew that this engine would require a borescope with a 4 mm diameter, which we do not have in house, so we called Ashtead Technology at 8 am and by 10 am they had called back to confirm that an instrument would be ready for collection.

“We routinely hire inspection equipment from Ashtead because it provides us with access to an enormous fleet of the latest technologies. As a result, we are able to employ the best instrument for every job, without having to pass on the costs of purchase and ongoing maintenance to our customers.”

Rob collected the IPLEX NX borescope on his way to Rwanda via Gatwick Airport on 21 February 2018 and the engine inspection was undertaken the following day.

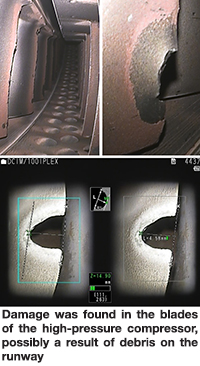

The CRJ900 jet is powered by two turbofan engines mounted on the sides of the rear section of the fuselage. The inspection took around six hours and Rob said: “It was clear that the engine had suffered catastrophic damage. Using the stereo measurement capability of the IPLEX NX, it was possible to measure the flaws and compare them with the limits specified in the maintenance manual.

“Damage was found in the blades of the high-pressure compressor. There was no evidence of a bird strike, so the damage may have been caused by a small item of debris on the runway.

Occasionally, borescope inspections find damage such as an imprint from a nut of bolt, for example, but in this instance the damage appeared to have been caused by a stone or a similar

object.”

Ashtead’s Steve Drake said: “The IPLEX NX is ideal for this type of work; it combines a high-pixel digital image sensor, an ultra-bright laser diode light system and a unique ‘image noise-reducing’ PulsarPic processor to automatically adjust light output and to deliver the clearest images possible in changeable inspection conditions. As a result, users are able to study the subtlest

defects in the darkest or most reflective places and over wide areas, producing clear, bright images.”

With wide-field stereo measurement capability, the IPLEX NX measures a range of defect characteristics, including distance, point-to-line, depth and area/lines. The instrument’s multi-spot ranging function enables real-time measurement of the distance from the scope tip to multiple points on the inspection surface. This provides surface shape information with no pause or break in the inspection.

Rob said: “The ability to take precise measurements and to support them with high-quality images and video means that our clients are able to make important decisions with the highest degree of

confidence.

“There are basically three possible outcomes from an inspection. The aircraft may be given a clean bill of health to continue flying or it may be authorised for a single flight back to base so that repairs can be undertaken. Alternatively, as was the case in Kigali, the aircraft is grounded so that the engine can be replaced.

“The repair bill for this engine is likely to exceed US$1 million, so it is extremely important that the operator is provided with accurate, clear evidence of failure. The IPLEX NX is essential for the achievement of that goal.”

www.ashtead-technology.com