New features added to condition monitoring system

18/02/2020

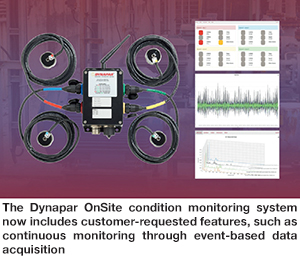

Dynapar has introduced upgrades to its Dynapar OnSite™ condition monitoring system, offering greater flexibility, compatibility and adaptability to help users successfully anticipate breakdowns and plan maintenance schedules accordingly.The OnSite system was designed to track machine condition and combine high-quality vibration data with ease of use and scalability. More than just an alarm, the OnSite system provides cost-effective vibration analysis tools to keep the rotating assets of the machine operating at full capacity. This powerful cloud-based tool provides users with the capability to be proactive, rather than reactive, by delivering 24/7 remote condition monitoring.

Users wanted the Dynapar OnSite condition monitoring system to have the option to monitor real-time data continuously and adapt to their quickly changing applications. In response, Dynapar developed event-based data acquisition technology. This new feature allows users to configure the OnSite system with application-specific triggers or thresholds. The OnSite system continuously listens for vibrations, temperatures or speed events once per minute. When a threshold is met or exceeded, the system will respond by sending data to the cloud, where it is compared to user-created alarm levels. If an alarm condition is reached, the systems notifies users via email or SMS.

To provide more flexible connection options, especially for applications where wireless connections may not be an option, the Dynapar OnSite system is now capable of transmitting condition monitoring data from the user’s machine to its cloud-based portal by wired Ethernet. A wired network provides security, convenience and reliability through physically connecting the OnSite system to the network. Dynapar also offers users data communication via wireless network options such as Wi-Fi and cellular.

The OnSite system measures vibration and temperature using four vibration sensors. It can also connect to any quadrature encoder, integrating speed to provide real-time running conditions and rotational frequency data for vibration analysis of rotating assets. Based on popular demand, the OnSite system is now compatible with a variety of input devices such as laser tachs and proximity switches, in addition to standard quadrature encoders. These external devices are used to capture speed, which is integrated with vibration and temperature data to provide the most accurate depiction of the machine’s condition.

Vibration data can now be displayed in velocity root mean square (VRMS) in addition to acceleration, allowing users to set categories of alarms based on the ISO 10816 vibration severity standard. This feature provides users with guidance for quickly creating alarms for rotating assets.

Additional upgrades include improved alarm configuration options. New configurations consist of compound alarms and tiered notifications for vibration, speed and temperature conditions. Users of the OnSite system are now able to configure custom alarm templates that can be copied and pasted to other assets. Traditionally, only the more critical assets, such as turbines and large generators, received 24/7 condition monitoring. However, rotating assets such as motors, pumps and fans are what keep cooling towers, air handlers, blowers, conveyors, overhead cranes and other kinds of machinery in business. Each asset must be in pristine condition to keep the whole operation running smoothly. No matter the size or function, if these assets fail unexpectedly they can potentially stop production. The Dynapar OnSite system enables organisations to monitor virtually any asset of interest, avoiding unscheduled downtime with remote condition monitoring.

Additional upgrades include improved alarm configuration options. New configurations consist of compound alarms and tiered notifications for vibration, speed and temperature conditions. Users of the OnSite system are now able to configure custom alarm templates that can be copied and pasted to other assets. Traditionally, only the more critical assets, such as turbines and large generators, received 24/7 condition monitoring. However, rotating assets such as motors, pumps and fans are what keep cooling towers, air handlers, blowers, conveyors, overhead cranes and other kinds of machinery in business. Each asset must be in pristine condition to keep the whole operation running smoothly. No matter the size or function, if these assets fail unexpectedly they can potentially stop production. The Dynapar OnSite system enables organisations to monitor virtually any asset of interest, avoiding unscheduled downtime with remote condition monitoring.