USL gets bigger and spreads wider

11/03/2008

For more than 15 years, Ultrasonic Sciences Ltd (USL) has successfully installed custom ultrasonic inspection systems in many countries. In recent months, the scale and geographic range of these systems has increased dramatically, with large installations in China, Russia and Romania and smaller units in Australia, Ireland and the USA. In this way, USL is sailing against the wind as far as UK-based manufacturing is concerned, although it is noticeable that some of the numerous parts which go into these systems are marked 'Made in China'!

For more than 15 years, Ultrasonic Sciences Ltd (USL) has successfully installed custom ultrasonic inspection systems in many countries. In recent months, the scale and geographic range of these systems has increased dramatically, with large installations in China, Russia and Romania and smaller units in Australia, Ireland and the USA. In this way, USL is sailing against the wind as far as UK-based manufacturing is concerned, although it is noticeable that some of the numerous parts which go into these systems are marked 'Made in China'!The most recent of these is a delivery to an aerospace composites manufacturer in Harbin, China. The size of this system is illustrated in the photograph (Figure 1)

where a 13-tonne consignment of the major structural parts is being loaded at the USL factory for delivery. The system is a 17-axis scanner for inspection of double curved, complex geometry composite components manufactured for Airbus, Boeing and other aircraft makers. The overall size of the assembled machine is 11 x 3 x 4.5 m, capable of inspecting parts within a scan volume of 8 x 1.5 x 3 metres using a squirter technique in both through-transmission and pulse echo modes. Similar systems have been supplied in the last few years to customers in the UK and Netherlands (Figure 2) and this will continue following other orders received since the beginning of 2008.

where a 13-tonne consignment of the major structural parts is being loaded at the USL factory for delivery. The system is a 17-axis scanner for inspection of double curved, complex geometry composite components manufactured for Airbus, Boeing and other aircraft makers. The overall size of the assembled machine is 11 x 3 x 4.5 m, capable of inspecting parts within a scan volume of 8 x 1.5 x 3 metres using a squirter technique in both through-transmission and pulse echo modes. Similar systems have been supplied in the last few years to customers in the UK and Netherlands (Figure 2) and this will continue following other orders received since the beginning of 2008.Pre-delivery acceptance tests witnessed by the customer at the USL factory showed the capability of the system in comparison with their existing scanner, which was supplied a short time ago by a major NDT equipment supplier. This prompted them to make a comment to USL's Chinese engineer that "If our XXX system is a child, then the USL system is an idol".

Although this is a large system, it does not approach the size of an immersion scanner installed in China in the final quarter of 2007 (Figure 3). This is over 23 m long and 6 m wide and is used for inspection of aerospace quality aluminium plate at Southwest Aluminium in Chongqing. Currently this operates with 16 ultrasonic channels but it has the built-in capability to increase to 32 channels as the factory throughput increases. In common with other USL systems for plate inspection, it incorporates USL PC-based ultrasonics with exceptional sensitivity, near-surface resolution and immunity to external noise.

Although this is a large system, it does not approach the size of an immersion scanner installed in China in the final quarter of 2007 (Figure 3). This is over 23 m long and 6 m wide and is used for inspection of aerospace quality aluminium plate at Southwest Aluminium in Chongqing. Currently this operates with 16 ultrasonic channels but it has the built-in capability to increase to 32 channels as the factory throughput increases. In common with other USL systems for plate inspection, it incorporates USL PC-based ultrasonics with exceptional sensitivity, near-surface resolution and immunity to external noise. The probe manipulator maintains the correct beam incidence by actively adapting the probe angles during scanning to follow undulations in the surface of the plate. The system also adjusts the delay and width of the monitor gates according to the instantaneous measured thickness – otherwise known as 'elastic gates'.

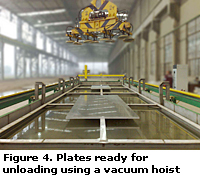

One newer feature in this system is a motorised lift assembly which raises the bed of the scanner so that tested plate is above the water level. With a load capacity of more than 10 tonnes, this permits simple loading and unloading of plates using a vacuum hoist (Figure 4). Due to the size of this scanner, it was not practicable to build the main structure in the UK and ship it to the

One newer feature in this system is a motorised lift assembly which raises the bed of the scanner so that tested plate is above the water level. With a load capacity of more than 10 tonnes, this permits simple loading and unloading of plates using a vacuum hoist (Figure 4). Due to the size of this scanner, it was not practicable to build the main structure in the UK and ship it to the customer. Accordingly, it was built on-site in China to designs provided by USL. The multi-axis scanning bridge, manipulators, electronics and associated components were shipped from the UK and assembled on to the pre-manufactured structure by USL engineers over a two-week period.

A similar, but slightly smaller, system was installed during 2007 at another aluminium manufacturer in Romania. This followed a multi-channel immersion testing installation for titanium plate at VSMPO in Russia, which is the world's largest manufacturer of titanium alloy products.

These deliveries have helped USL increase turnover in a single year by almost 50%, and this is compared with the previous year, which was already a record.

www.ultrasonic-sciences.co.uk