Schaeffler SpindleSense reduces machine downtime and increases utilisation of machine capacity

04/11/2019

The main spindle is crucial to the performance capability of the complete machine tool. It is at the heart of the machine and largely defines the achievable cutting capacity, surface quality and precision. In turn, the spindle bearing support is one of the most heavily loaded components because it must transmit machining forces precisely at very high speeds for long periods of time and the risk of collisions can never be ruled out. It therefore comes as no surprise that the majority of machine tool downtime can be traced back to defective spindles, particularly as a result of collisions and continuous undetected overloads. In milling operations, for example, the combination of high radial loads, long tool protrusions and high speeds leads to particularly high loads and unfavourable kinematic conditions on the spindle bearing in the vicinity of the tool. These unfavourable, and in some cases impermissible, loads occur because operators have not had a suitable tool with which to monitor borderline loads on spindle bearings. Schaeffler has now solved this problem with its new SpindleSense monitoring system.

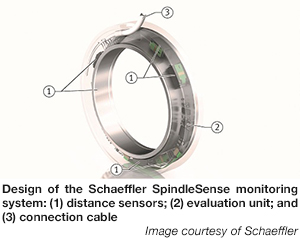

The main spindle is crucial to the performance capability of the complete machine tool. It is at the heart of the machine and largely defines the achievable cutting capacity, surface quality and precision. In turn, the spindle bearing support is one of the most heavily loaded components because it must transmit machining forces precisely at very high speeds for long periods of time and the risk of collisions can never be ruled out. It therefore comes as no surprise that the majority of machine tool downtime can be traced back to defective spindles, particularly as a result of collisions and continuous undetected overloads. In milling operations, for example, the combination of high radial loads, long tool protrusions and high speeds leads to particularly high loads and unfavourable kinematic conditions on the spindle bearing in the vicinity of the tool. These unfavourable, and in some cases impermissible, loads occur because operators have not had a suitable tool with which to monitor borderline loads on spindle bearings. Schaeffler has now solved this problem with its new SpindleSense monitoring system.The first production-ready SRS sensor ring units, including radial and axial measuring ring with an inside diameter of 70 mm, will soon be available for customers to test in practical applications. Additional sizes with 80 mm and 100 mm inside diameters will be available by the end of the year. All units have a standard width of 16 mm.

The scope of delivery includes an SST set-up service tool, with which SpindleSense can be parameterised and put into operation.

The sensor system integrated into the spindle bearing measures the displacement of the spindle shaft under load at a very high resolution and in five spatial directions: three translational and two rotatory. The sensor ring transmits an electrical warning signal to the machine’s control system if the deflections measured on the rolling elements exceed a specific threshold, which is set individually for every spindle and machine type. The threshold is based on an assessment of operation-related bearing parameters such as pressure, spin/roll ratio and cage pocket clearance, into which Schaeffler has integrated its many years of expertise in rolling bearings.

All of the software and the required algorithms are integrated into the 16 mm-wide sensor ring. No further components are required for the system. The system is locally functional and transmits an individual warning signal to the machine’s control system, which makes the following applications possible:

- Detecting a crash (collision): The sensor technology is capable of signalling an overload at a digital output within 2 ms. This allows serious subsequent damage to be minimised or even prevented through fast deactivation of the drive.

- Long-term protection for machine tool spindles: In practice, continuous mechanical spindle bearing overloads are not immediately identified. In contrast, SpindleSense immediately triggers a warning signal when the overload is parameterised accordingly. The operator can adjust the machining program right after the first manufactured part and reduce the spindle load by using a new tool or modified cutting values, or by employing a more suitable tool type. The operator thus achieves lower and less numerous peak loads and so benefits from a longer spindle operating life with fewer instances of machine tool downtime, which ultimately means more production time and reduced repair costs.

Two options are available for outputting the measured values. Variant C-A0 transmits alarm signals as soon as the individually defined limit values for the bearing load and kinematics are reached. Variant C-A1 outputs the measured radial and axial displacements, including tilting via a controller area network (CAN) bus. Machine tool and spindle manufacturers can use these displacement values to develop analysis tools for optimising the utilisation of spindle capacity, for example by visualising the deflection collective measured by the sensor ring as a load collective. The machine operator will know the degree to which the spindle capacity in each machining process is being utilised as a percentage with a high level of accuracy and will, therefore, be able to adjust the machining process even more precisely in terms of capacity utilisation and operating life for each machine. This means that harmful overloads will be prevented despite maximum spindle loads. Safe operation in the limit range allows the operator to increase their productivity and also to benefit from longer spindle operating life and less frequent periods of machine downtime.

The measured displacements that are outputted via CAN bus can also be used for zero-point compensation. This makes it possible to produce the same quality with larger cutting values or higher quality with unmodified cutting values. Monitoring of the maximum displacement can also be used for quality assurance.

Compared to mechanical systems, ie passive overload, the Schaeffler SpindleSense does not just protect the spindle in the event of a collision; it is also a revolutionary system for safely maximising the utilisation of the spindle capacity. For the first time ever, machine manufacturers can now offer their customers a highly effective tool for increasing productivity, machine availability and quality.