UKAS approval for specialist Exova NDT lab

04/07/2012

A specialist laboratory of global testing group Exova has been approved to carry out advanced, bespoke tests to the highest industry standard.The Droitwich, Worcestershire, laboratory, which specialises in

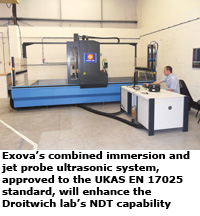

non-destructive testing, recently invested in a combined immersion and jet probe ultrasonic inspection system, which has already been approved by Nadcap and helicopter giant AgustaWestland.

non-destructive testing, recently invested in a combined immersion and jet probe ultrasonic inspection system, which has already been approved by Nadcap and helicopter giant AgustaWestland.Now the equipment has been approved to the UKAS EN 17025 standard, the main industry approval, which recognises the competency of testing and calibration laboratories.

The new approval means the cutting-edge test-frame can now be used to carry out work for customers looking for the UKAS accreditation.

The combined immersion and jet probe ultrasonic inspection system supplements and enhances the lab’s significant NDT capability. It is designed to be highly versatile and accommodate both metallic and composite materials with flat and curved surfaces and varying geometries.

The system is capable of pulse-echo immersion inspection of curved components using a multi-axis manipulator in the immersion tank. Through-transmission inspection is carried out using water jets mounted above the immersion tank.

The main system specifications include a range of 2000 mm length and 1000 mm width, with a speed of 750 mm/s and 250 mm/s. The multi-axis manipulator (immersion) has a range of 400 mm on the Z axis, 225 degrees on the T1 axis and 360 degrees on T2. Speed is 200 mm/s, 30 degrees/s and 30 degrees/s, respectively.

Exova Droitwich is part of a network of specialist NDT labs, including Dudley and Nuneaton, also in the Midlands, offering services to industry sectors including power generation, aerospace, automotive, oil & gas and defence.

The NDT facilities hold a range of national, international and prime manufacturer-based approvals, also including Rolls-Royce, BAE Systems, Goodrich and Moog.

NDT services available from Exova include:

- X-ray up to 450 kV and gamma radiography

- Magnetic particle inspection

- Liquid penetrant inspection

- Passivation

- Visual

- Ultrasonic, both contact and IUT and phased array

- Eddy current.

Barnabas Mapuranga of Exova Droitwich said: “The bespoke test-frame was a significant investment for Exova, and the quality of our work has already been recognised by Nadcap and Agusta Westland.

“This latest approval from UKAS is a further sign to our global customers that our testing services are the best available, and we look forward to working with a number of industries that will benefit from our bespoke testing.”

With over 40 years’ experience, Exova specialises in testing across nine key sectors, from food and pharmaceuticals to aerospace, oil & gas, fire, engineering and construction.

Exova operates 110 permanent facilities in 22 countries and employs more than 3,500 people throughout Europe, North America, South America, the Middle East and Asia/Asia Pacific.

www.exova.com