Lubrication Analysis

What it is ...

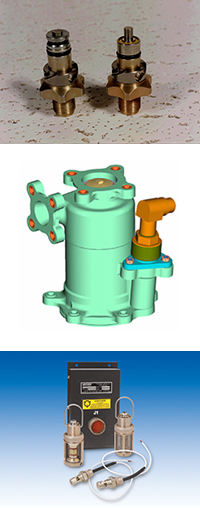

This method is used in systems employing petroleum-based or synthetic fluids such as lubricants or working media (hydraulic systems) and is based on analysing the condition of the fluid and the wear debris entering the circulating fluid system. The analysis of the fluid condition identifies the changes in the properties of the fluid and ingress of contaminants for example dirt, water or oxidised fluid products. This enables the analyst to predict the onset of wear of particular components. Wear debris analysis studies the wear metals present in the fluid to predict the type of wear, for example sliding wear or fatigue, it’s likely cause and severity; allowing a reasonable prognosis to be made. Technologies exist to allow the health of the lubricant and analysis of the wear particles both offline in a laboratory, and online in real time on the machine being monitored.

This method is used in systems employing petroleum-based or synthetic fluids such as lubricants or working media (hydraulic systems) and is based on analysing the condition of the fluid and the wear debris entering the circulating fluid system. The analysis of the fluid condition identifies the changes in the properties of the fluid and ingress of contaminants for example dirt, water or oxidised fluid products. This enables the analyst to predict the onset of wear of particular components. Wear debris analysis studies the wear metals present in the fluid to predict the type of wear, for example sliding wear or fatigue, it’s likely cause and severity; allowing a reasonable prognosis to be made. Technologies exist to allow the health of the lubricant and analysis of the wear particles both offline in a laboratory, and online in real time on the machine being monitored.Wear debris analysis techniques include studying the wear particles under magnification to identify:

- Shape

- Size

- Number of particles

- Type

- Chemistry

- Morphology and condition of particles.

- Viscometry

- Particle sizing

- FTIR

- ICP

- Image analyser

- Ferrography

- AAS

- XRF

- SEM.