Phoenix on board as Schiehallion inspection gets underway

04/08/2011

Equipment produced by Phoenix Inspection Systems is being used for testing one of the world’s largest floating oil production facilities.

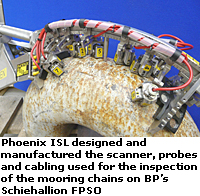

Equipment produced by Phoenix Inspection Systems is being used for testing one of the world’s largest floating oil production facilities.The system is being used to inspect the mooring chains on BP’s floating production, storing and offloading (FPSO) vessel in the Schiehallion oilfield, 175 miles west of the Shetlands. Phoenix was contracted to design and manufacture a scanner, probes and cabling by TWI (The Welding Institute), which has developed the inspection protocol and is responsible for carrying out the testing.

The Schiehallion FPSO is one of the largest vessels of its type in the world, with a processing capacity of around 200,000 barrels a day and a storage capacity of around 950,000 barrels. Oil and gas produced from the 42 subsea wells in the Schiehallion field are piped to the FPSO for processing and then offloaded onto a shuttle boat for delivery to the Sullom Voe terminal.

The vessel, which was built at Harland and Wolff in Belfast, has been in service since 1998. The inspection is part of a wider maintenance programme.

The FPSO is anchored by 14 mooring chains, each 6.25 inches in diameter, to piles in the seabed below. Together they represent the largest studless mooring chain link ever produced. The chains are due for replacement but must first be inspected to ensure they can be safely removed. The inspection is focusing on the point where the chains fix onto the ship. The whole operation is taking place underwater, with the equipment being carried by divers and fixed into position.

Phoenix Project Manager Chris Gregory has made two trips to the Schiehallion to oversee the implementation of the Phoenix equipment. He said: “We are pleased to be working once again alongside TWI, which is renowned worldwide for its expertise. This project posed a number of challenges in terms of equipment design as all kit must be capable of operating underwater in the harsh environment of the North Sea, yet small enough to be transported by divers and quick to assemble and fit into position.”

Karl Quirk, Managing Director of Phoenix Inspection Systems, added: “This is one of a number of high-profile sub-sea projects we have worked on which demonstrate Phoenix’s problem-solving capabilities. Others include making underwater probes for the rescue operation following the sinking of the Prestige off the coast of Spain in 2002, and producing equipment and inspection design for a complex project to test a production manifold for Shell in the Norwegian Sea in 2004.”

www.phoenixisl.co.uk