ACPD

Alternating Current - Potential Drop

AC-PD – Alternating Current - Potential Drop – is an electrical-magnetic NDT method where an electric current is passed between two contacts placed on the component under test. The presence of a defect between the contacts increases the electrical resistance and hence there is a change in potential (voltage) when compared to a defect free part of the component. This change is used to detect and size defects.

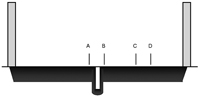

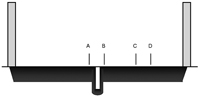

The current can be direct current (DC-PD) or alternating current as in AC-PD. Alternating current flows close to the surface of the component due to the skin effect as shown in Figure 1 and the depth of penetration depends on the AC frequency. When a defect extends below the depth of penetration, the current flows down the faces and under the defect as shown in Figure 2.

Figure 1

Figure 2

The difference in potential measured between two points separated on the surface by a known distance and placed across the crack (A-B) will be greater than the potential difference between two points separated by the same distance and placed on good material (C-D) due to the greater current path. The depth of the crack can be predicted by comparing the ratios of the PD between A-B and C-D. However, the shape of the crack, the length to depth ratio and the presence of any other cracks close by need to be taken into consideration when predicting the size from the AC-PD measurement.

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org

The current can be direct current (DC-PD) or alternating current as in AC-PD. Alternating current flows close to the surface of the component due to the skin effect as shown in Figure 1 and the depth of penetration depends on the AC frequency. When a defect extends below the depth of penetration, the current flows down the faces and under the defect as shown in Figure 2.

Figure 1

Figure 2

The difference in potential measured between two points separated on the surface by a known distance and placed across the crack (A-B) will be greater than the potential difference between two points separated by the same distance and placed on good material (C-D) due to the greater current path. The depth of the crack can be predicted by comparing the ratios of the PD between A-B and C-D. However, the shape of the crack, the length to depth ratio and the presence of any other cracks close by need to be taken into consideration when predicting the size from the AC-PD measurement.

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org