XRF

X-Ray Fluorescence

XRF – X-Ray Fluorescence – is an analysis technique used in Positive Material Identification (PMI) equipment. X-rays are fired from the XRF equipment at the component requiring analysis.

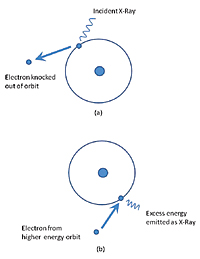

XRF – X-Ray Fluorescence – is an analysis technique used in Positive Material Identification (PMI) equipment. X-rays are fired from the XRF equipment at the component requiring analysis. The incident X-rays knock low-energy electrons out of their orbit around the atoms, as shown in (a) in the Figure. This leaves the atom unstable so the removed low-energy electron is replaced by a higher energy electron and the excess energy is given out as X-rays, as shown in (b). The emitted X-rays are detected by a detector in the XRF equipment. The equipment is arranged so that the X-rays transmitted by the XRF equipment are incident on the component but do not affect the detector.

Each chemical element emits an X-ray with a unique energy value. So, by measuring the energies of the X-rays received at the detector, the specific elements generating the X-rays can be identified. The composition of the elements in the component can be calculated by measuring the number of X-ray signals received at each particular energy level. Once the element composition of the component is identified, it is a simple computer look-up task to identify the alloy grade.

For more information on XRF see:

http://www.innovx.com/en/technology/fluorescence

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org