LRUT

Long-Range Ultrasonic Testing

LRUT – Long-Range Ultrasonic Testing – is a method for the rapid screening of pipework for corrosion and erosion. The technique differs from conventional ultrasonic testing in that it uses plate or Lamb waves instead of bulk waves and the frequency is in the order of kHz rather than MHz. Plate waves penetrate the whole thickness of the plate and the ratio of plate thickness to the ultrasonic wavelength is such that the waves on the two surfaces interact.

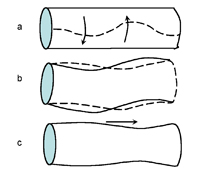

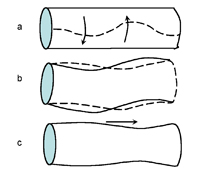

When generated in pipes these plate waves are known as guided waves. There are different modes of guided wave and the Figure shows three main ones. Wave (a) is a torsional wave, in which the pipe twists in one direction and then the next. Wave (b) is a flexural wave, and wave (c) is a longitudinal wave, which travels as a bulge in the pipe wall.

Guided waves are known as dispersive because the velocity of the wave mode changes with frequency. A pulse contains a range of different frequencies and the higher frequencies will travel faster than the lower ones. The velocity also depends upon the wave mode, the pipe diameter and the pipe thickness.

The signals are displayed in a conventional A-scan display but because of the different wave modes and the different velocities the received signal can be complicated and require careful analysis.

LRUT is used for the detection of both internal and external corrosion/erosion in pipes which can be thermally insulated, coated or buried. It can also detect corrosion under pipe supports, hidden welded joints and irregularities in girth weld shape.

For more information on LRUT see:

http://www.imperial.ac.uk/ndt/public/publications/LongRange_GW_Review.pdf

http://www.lrucm.eu.com/publications/lrut_new_markets_for_new_technology.pdf

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org

When generated in pipes these plate waves are known as guided waves. There are different modes of guided wave and the Figure shows three main ones. Wave (a) is a torsional wave, in which the pipe twists in one direction and then the next. Wave (b) is a flexural wave, and wave (c) is a longitudinal wave, which travels as a bulge in the pipe wall.

Guided waves are known as dispersive because the velocity of the wave mode changes with frequency. A pulse contains a range of different frequencies and the higher frequencies will travel faster than the lower ones. The velocity also depends upon the wave mode, the pipe diameter and the pipe thickness.

The signals are displayed in a conventional A-scan display but because of the different wave modes and the different velocities the received signal can be complicated and require careful analysis.

LRUT is used for the detection of both internal and external corrosion/erosion in pipes which can be thermally insulated, coated or buried. It can also detect corrosion under pipe supports, hidden welded joints and irregularities in girth weld shape.

For more information on LRUT see:

http://www.imperial.ac.uk/ndt/public/publications/LongRange_GW_Review.pdf

http://www.lrucm.eu.com/publications/lrut_new_markets_for_new_technology.pdf

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org