AUT

Automated Ultrasonic Testing

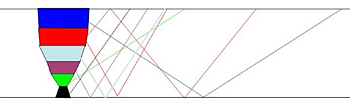

AUT – Automated Ultrasonic Testing – is a generic term which relates to the computerised collection of ultrasonic data, although, the three letter acronym AUT is now used to refer specifically to the automated ultrasonic inspection of pipe girth welds. Such systems have two sets of ultrasonic probes scanned circumferentially on either side of the weld. The sets of probes are selected to provide coverage of specific zones of the weld and the fusion face as shown in the figure below.

Both pulse echo and pitch catch mode can be utilised and more recently phased array probes have been used to provide the different beam angles.

The zones are typically of the order of a few millimetres. The data collected is usually displayed in strip form with the central column showing the root signals. The columns either side show the signals from each zone going up from the root to the cap on the respective side of the weld. In the absence of specific sizing techniques, a measure of the through wall size of an indication can be obtained by assessing the number of zones in which the signal is observed.

Many NDT equipment manufacturers produce AUT systems and give descriptions on their websites. ASTM International, originally known as the American Society for Testing and Materials (ASTM), has an active standard for AUT.

For more information on AUT see:

ASTM E1961-16 Standard Practice for Mechanized Ultrasonic Testing of Girth Welds Using Zonal Discrimination with Focused Search Units.

'Improved focusing for thick-wall pipeline girth weld inspections using phased arrays', M Moles, S Labbé and J Zhang, Insight, Vol 47 No 12, December 2005, pp 769-776.

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org

Both pulse echo and pitch catch mode can be utilised and more recently phased array probes have been used to provide the different beam angles.

The zones are typically of the order of a few millimetres. The data collected is usually displayed in strip form with the central column showing the root signals. The columns either side show the signals from each zone going up from the root to the cap on the respective side of the weld. In the absence of specific sizing techniques, a measure of the through wall size of an indication can be obtained by assessing the number of zones in which the signal is observed.

Many NDT equipment manufacturers produce AUT systems and give descriptions on their websites. ASTM International, originally known as the American Society for Testing and Materials (ASTM), has an active standard for AUT.

For more information on AUT see:

ASTM E1961-16 Standard Practice for Mechanized Ultrasonic Testing of Girth Welds Using Zonal Discrimination with Focused Search Units.

'Improved focusing for thick-wall pipeline girth weld inspections using phased arrays', M Moles, S Labbé and J Zhang, Insight, Vol 47 No 12, December 2005, pp 769-776.

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org