FCC and BCC

Face Centred Cubic and Body Centred Cubic

FCC – Face Centred Cubic – and BCC – Body Centred Cubic – are descriptions of the arrangement of atoms in crystal structures. Most metal and alloys are crystalline, which means that their atoms arrange themselves in an ordered pattern.

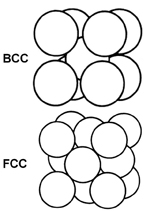

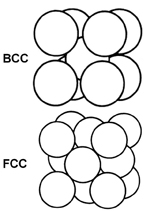

Ferritic steels can contain several phases, including ferrite, pearlite and martensite, and all of these phases have the crystal structure of BCC, ie one atom at the eight corners of a cube and one in the centre of the cube. Austenitic steels have austenite as their primary phase, with the smallest building block of the crystal structure of FCC, ie one atom at the eight corners of a cube and one in the centre of each of the six faces. The unit groupings of BCC and FCC are shown in the picture. This is the smallest representation of a repeated pattern.

Ferritic steels can contain several phases, including ferrite, pearlite and martensite, and all of these phases have the crystal structure of BCC, ie one atom at the eight corners of a cube and one in the centre of the cube. Austenitic steels have austenite as their primary phase, with the smallest building block of the crystal structure of FCC, ie one atom at the eight corners of a cube and one in the centre of each of the six faces. The unit groupings of BCC and FCC are shown in the picture. This is the smallest representation of a repeated pattern.

The structure of the atoms affects the properties of the material, for example FCC metals and alloys have very good ductility. Each crystal (grain) has its own ordered array of atoms and where the grains interact with each other there is a mismatch between the ordered atoms producing a grain boundary. The crystal structure contains imperfections, such as point defects (for example solute atoms, vacancies) and dislocations, and these govern many of the properties of the material.

Alloying and processing (heat treatment, rolling etc) can be used to modify the crystal structure and produce material with the desired properties. For example, the addition of >11% chromium to iron will dramatically improve its corrosion resistance (ie passive); this group of materials are know as stainless steels. Stainless steels can be ferritic (BCC), austenitic (FCC), martensitic (BCC) or a combination of two structures (duplex). Alloying elements can be added to promote FCC (for example nickel) or BCC structures (for example chromium).

Stainless steels have a wide range of properties. Austenitic stainless steels are easy to fabricate and weld, have excellent corrosion resistance, are non-magnetic, exhibit good ductility and toughness with moderate strength and good creep resistance. Ferritic stainless steels have good corrosion resistance, are moderate to form and weld, have moderate mechanical properties and are magnetic.

The sound and electro-magnetic properties are governed by the microstructure and care has to be taken in choosing the most appropriate NDT method to inspect a material and using the correct material properties, for example ultrasonic velocity.

For more information on BCC and FCC see:

W D Callister, Materials Science and Engineering: An Introduction, 8th Edition, 2010, Wiley.

Thanks to D Ludlow for his contribution to this text.

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org

Ferritic steels can contain several phases, including ferrite, pearlite and martensite, and all of these phases have the crystal structure of BCC, ie one atom at the eight corners of a cube and one in the centre of the cube. Austenitic steels have austenite as their primary phase, with the smallest building block of the crystal structure of FCC, ie one atom at the eight corners of a cube and one in the centre of each of the six faces. The unit groupings of BCC and FCC are shown in the picture. This is the smallest representation of a repeated pattern.

Ferritic steels can contain several phases, including ferrite, pearlite and martensite, and all of these phases have the crystal structure of BCC, ie one atom at the eight corners of a cube and one in the centre of the cube. Austenitic steels have austenite as their primary phase, with the smallest building block of the crystal structure of FCC, ie one atom at the eight corners of a cube and one in the centre of each of the six faces. The unit groupings of BCC and FCC are shown in the picture. This is the smallest representation of a repeated pattern.The structure of the atoms affects the properties of the material, for example FCC metals and alloys have very good ductility. Each crystal (grain) has its own ordered array of atoms and where the grains interact with each other there is a mismatch between the ordered atoms producing a grain boundary. The crystal structure contains imperfections, such as point defects (for example solute atoms, vacancies) and dislocations, and these govern many of the properties of the material.

Alloying and processing (heat treatment, rolling etc) can be used to modify the crystal structure and produce material with the desired properties. For example, the addition of >11% chromium to iron will dramatically improve its corrosion resistance (ie passive); this group of materials are know as stainless steels. Stainless steels can be ferritic (BCC), austenitic (FCC), martensitic (BCC) or a combination of two structures (duplex). Alloying elements can be added to promote FCC (for example nickel) or BCC structures (for example chromium).

Stainless steels have a wide range of properties. Austenitic stainless steels are easy to fabricate and weld, have excellent corrosion resistance, are non-magnetic, exhibit good ductility and toughness with moderate strength and good creep resistance. Ferritic stainless steels have good corrosion resistance, are moderate to form and weld, have moderate mechanical properties and are magnetic.

The sound and electro-magnetic properties are governed by the microstructure and care has to be taken in choosing the most appropriate NDT method to inspect a material and using the correct material properties, for example ultrasonic velocity.

For more information on BCC and FCC see:

W D Callister, Materials Science and Engineering: An Introduction, 8th Edition, 2010, Wiley.

Thanks to D Ludlow for his contribution to this text.

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org