RFEC

Remote Field Eddy Current

RFEC – Remote Field Eddy Current – is an electromagnetic technique particularly suited to the examination of ferromagnetic tubes from the inner surface. An exciter coil generates a magnetic field on the inside of the tube which in turn generates eddy currents within the tube wall. The frequency is selected so that the skin depth is approximately equal to the wall thickness and so eddy currents are generated throughout the wall.

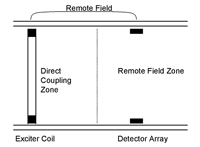

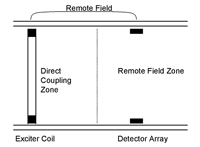

The tubular geometry means that the eddy currents at the inner surface rapidly cancel the magnetic field from the exciter coil within the direct coupling zone. But the eddy currents at the outer surface of the tube generate a magnetic flux which then becomes the main field at a distance two or more tube diameters along the tube from the exciter coil – in the remote field zone.

A sensor placed in the remote field zone detects the flux from the eddy currents in the tube wall. Defects at both the inner and outer diameter of the tube are detected by modifications to this flux providing an inspection of the full wall thickness.

The RFEC technology has many advantages including:

For more information on RFEC see:

Insight Vol 48 No 3, March 2006, pp 181–183.

ASM Handbook Vol 17, Nondestructive Evaluation and Quality Control, ASM International.

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org

The tubular geometry means that the eddy currents at the inner surface rapidly cancel the magnetic field from the exciter coil within the direct coupling zone. But the eddy currents at the outer surface of the tube generate a magnetic flux which then becomes the main field at a distance two or more tube diameters along the tube from the exciter coil – in the remote field zone.

A sensor placed in the remote field zone detects the flux from the eddy currents in the tube wall. Defects at both the inner and outer diameter of the tube are detected by modifications to this flux providing an inspection of the full wall thickness.

The RFEC technology has many advantages including:

- A simple exciter coil that can be less than one-third of the pipe diameter and does not need to be close to the wall.

- Simple and small sensor coils that do not need to contact the wall. Thus, the diameter of the coil array can be easily adjusted to match the pipe diameter yet pass through a small opening.

- Sensor coils close to the pipe wall provide sensitivity and accuracy comparable to standard Magnetic Flux Leakage (MFL) inspection tools. General pipe corrosion of 10% of the wall thickness or less is detected and measured with commercial units.

For more information on RFEC see:

Insight Vol 48 No 3, March 2006, pp 181–183.

ASM Handbook Vol 17, Nondestructive Evaluation and Quality Control, ASM International.

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org