EMAT

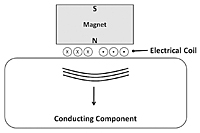

EMAT – Electromagnetic Acoustic Transducer for the contactless generation of ultrasonic waves. An EMAT comprises a magnet and an electrical coil (see the Figure). When a current is passed through the coil, eddy currents are induced in the component under test. The static magnetic field exerts a force on the eddy currents. If the current passing through the coil is an alternating current, then both the eddy currents and the force will change direction with the change in the current. The oscillating force causes the particles of the component to oscillate, generating an acoustic wave which then propagates through the component. For the EMAT to work, the component needs to be of electrically conducting material.

EMAT – Electromagnetic Acoustic Transducer for the contactless generation of ultrasonic waves. An EMAT comprises a magnet and an electrical coil (see the Figure). When a current is passed through the coil, eddy currents are induced in the component under test. The static magnetic field exerts a force on the eddy currents. If the current passing through the coil is an alternating current, then both the eddy currents and the force will change direction with the change in the current. The oscillating force causes the particles of the component to oscillate, generating an acoustic wave which then propagates through the component. For the EMAT to work, the component needs to be of electrically conducting material.EMATs have a number of advantages based on their ability to generate ultrasound in a component without the need for couplant. They can be used on components at high temperature and to inspect moving components. They can inspect through coatings and do not need surface preparation. EMATs can be designed to excite complex wave patterns and polarisations that would be difficult to realise with fluid-coupled piezoelectric probes. In particular, they can generate horizontally polarised (SH) shear waves. SH waves do not mode convert when striking surfaces that are parallel to the direction of polarisation and do not suffer the same distortion as the common, piezoelectric transducer generated, vertically polarised (SV) shear waves when propagating through austenitic material.

EMATs require strong magnetic fields and large currents, which has meant that the transducers have tended to be large compared to piezoelectric transducers. They also have to be designed for the particular application. EMAT efficiencies are also lower than piezoelectric transducers and so the sound beam is a lot weaker. However, the potential advantages have stimulated ongoing research to try to overcome these disadvantages.

For more information on EMATs see:

http://www2.warwick.ac.uk/fac/sci/physics/research/ultra/research/emat/

and

http://www.ndt-ed.org/EducationResources/CommunityCollege/Ultrasonics/EquipmentTrans/emats.htm

What the hec?! articles are not intended to be the definitive account on the topic or acronym in question. Readers’ comments and contributions are welcomed. Email: ndtnews@bindt.org